Method for preparing strawberry type inorganic particle-polyurea composite microspheres and super-hydrophobic coating thereof

A technology of inorganic particles and composite microspheres, applied in polyurea/polyurethane coatings, coatings, microsphere preparation, etc., can solve the problems of complex system components, cumbersome process steps, and long reaction time, and achieve the effect of simple system components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] At room temperature, 14.6 g of water and 70.4 g of acetonitrile were added to a 120 mL reaction flask, followed by the addition of 5.0 g of an aqueous dispersion of silicon dioxide (the amount of silicon dioxide was 2.0 g, and the particle size was 160 nm) and 10.0 g Methylcyclohexyl diisocyanate monomer. After the system was mixed evenly, the reaction bottle was sealed and placed in a constant temperature water bath at 50°C for 60 minutes. The product was put into a centrifuge tube and centrifuged at 8000r / min for 4min, the obtained solid was washed twice with acetonitrile and then dried in an oven at 100°C for 2h to obtain strawberry-type silica-polyurea composite microspheres.

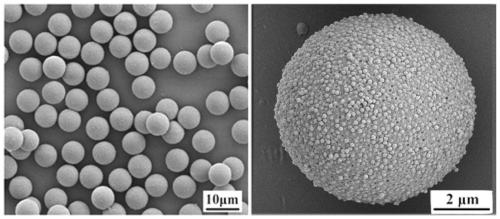

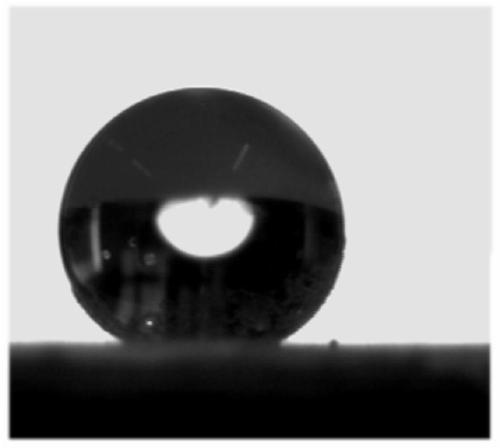

[0048] The yield of the obtained strawberry microspheres was 87.67%, the average particle size of the microspheres was 6.78 μm, and the polydispersity coefficient of the particle size was 1.006. The scanning electron microscope images of the microspheres are as figure 1 As shown, the left p...

Embodiment 2

[0051] At room temperature, 3.8g of water and 51.2g of acetonitrile were added to a 120mL reaction flask, followed by the addition of 15.0g of an aqueous dispersion of silicon dioxide (the amount of silicon dioxide was 6.0g, and the particle size was 340nm) and 30.0g Isophorone diisocyanate monomer. After the system was evenly mixed, the reaction bottle was sealed and placed in a constant temperature water bath at 70°C for 40 min. The product was subjected to suction filtration, and the obtained solid was washed twice with acetonitrile and then dried in an oven at 80° C. for 4 hours to obtain strawberry-shaped silica-polyurea composite microspheres.

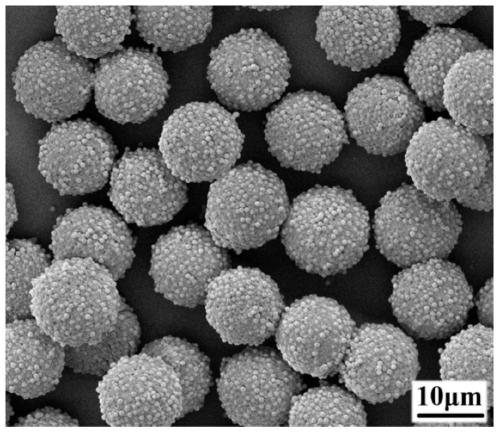

[0052] The productive rate of gained strawberry type microsphere is 94.97%, and the average particle diameter of microsphere is 12.85 μ m, and particle diameter polydispersity coefficient is 1.010; The scanning electron micrograph of microsphere is as follows: image 3 shown.

[0053] The obtained strawberry-shaped microspheres...

Embodiment 3

[0055] At room temperature, 14.3g of water and 63.2g of acetonitrile were added to a 120mL reaction flask, followed by the addition of 2.5g of an aqueous dispersion of silicon dioxide (the amount of silicon dioxide was 1.0g, and the particle size was 160nm) and 20.0g 4,4'-dicyclohexylmethane diisocyanate monomer. After the system was uniformly mixed, the reaction bottle was sealed and placed in a constant temperature water bath shaker at 30° C. to react at 140 osc / min for 120 min. Put the product into a centrifuge tube and centrifuge at 12000r / min for 2min. The obtained solid was washed twice with acetonitrile and dried in an oven at 80°C for 4h to obtain strawberry-type silica-polyurea composite microspheres.

[0056] The yield of the obtained strawberry microspheres was 92.55%, the measured average particle size of the microspheres was 10.13 μm, and the polydispersity coefficient of the particle size was 1.008.

[0057] The strawberry-shaped microspheres were bonded to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| viewing angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com