Transformer substation oil shortage equipment monitoring system based on wireless intelligent sensor

An equipment monitoring system and smart sensor technology, applied in signal transmission systems, instruments, etc., can solve the problems of sensor installation location restrictions, complex installation organization, cumbersome operation steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

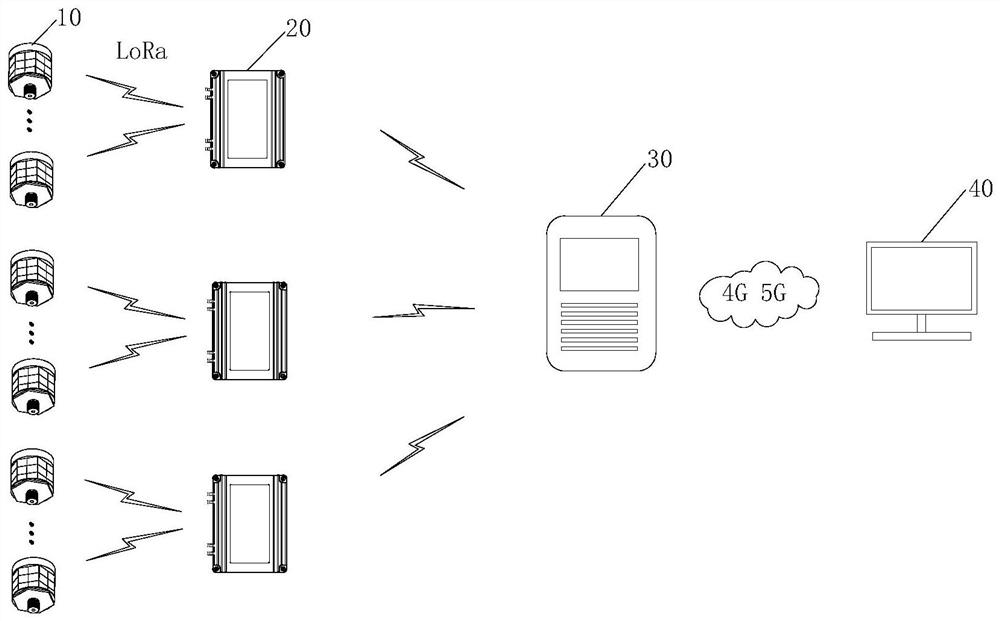

[0044] Such as Figure 1-11 As shown, it shows a specific embodiment of the present invention, as shown in the figure, the substation oil-less equipment monitoring system based on wireless smart sensors disclosed by the present invention includes:

[0045] - The front-end collection terminal 10 is used to collect the temperature and pressure detection data of the oil-less equipment in the substation and transmit them through the wireless module;

[0046] - The repeater 20 communicates wirelessly with the front-end collection terminal, receives data collected by multiple front-end collection terminals and performs remote transmission;

[0047] - The wireless communication gateway 30 receives the information transmitted by the repeater and uniformly transmits the grid communication module to the remote monitoring center 40;

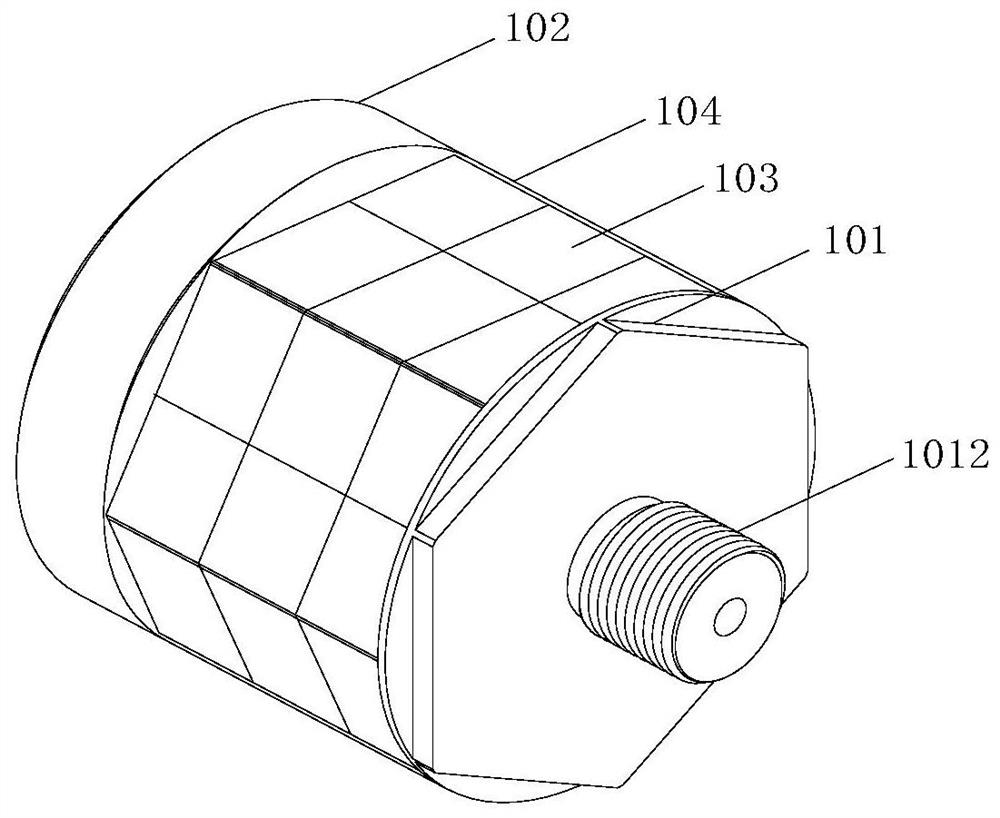

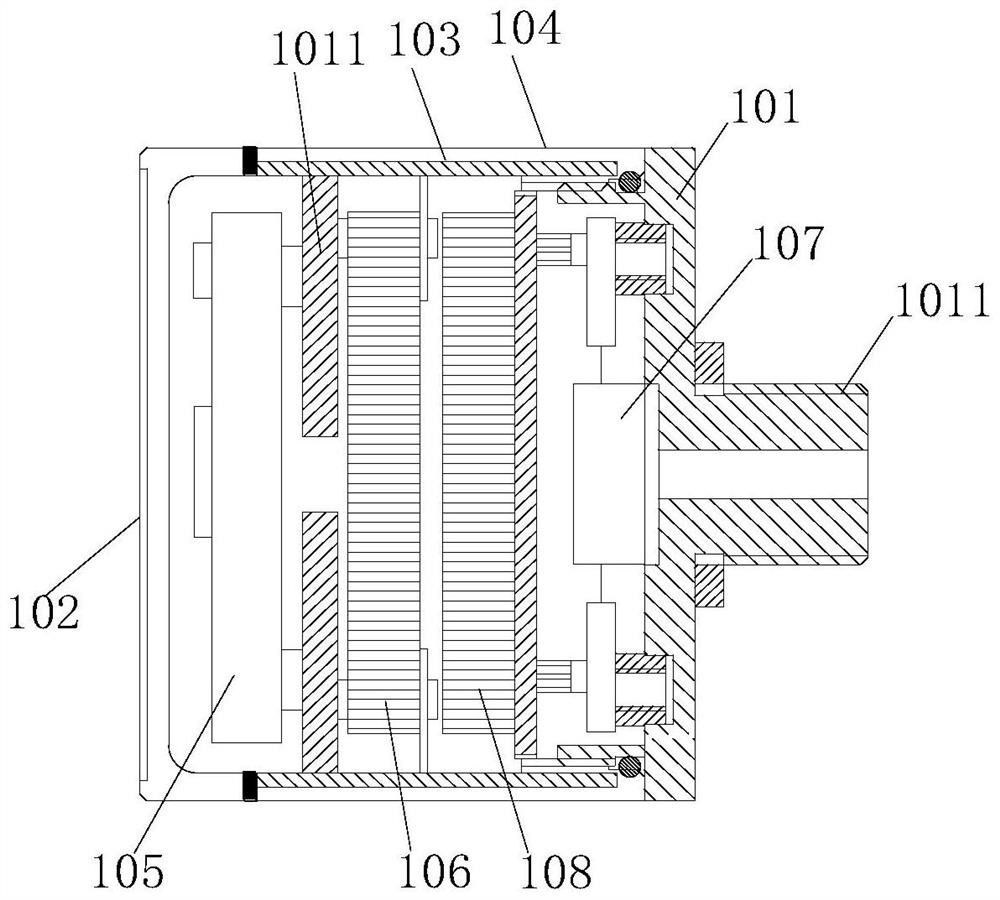

[0048] The front-end acquisition terminal 10 includes: an installation housing 101, and a barrier 1011 is arranged inside the installation housing 101, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com