Method for preparing ultra-pure hydrogen

An ultra-pure and high-purity technology, applied in chemical instruments and methods, hydrogen separation, hydrogen/synthesis gas production, etc., can solve the problems of complex process, large investment, and high cost, and achieve simple process, high process efficiency, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

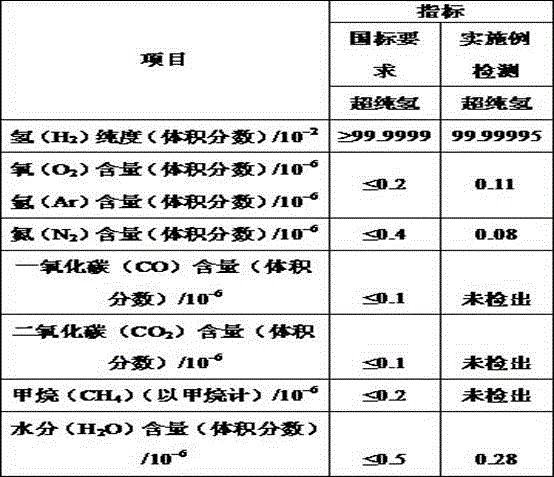

[0031] Through the above-mentioned production equipment, the preparation of high-purity oxygen is carried out according to the following process:

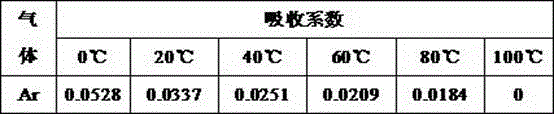

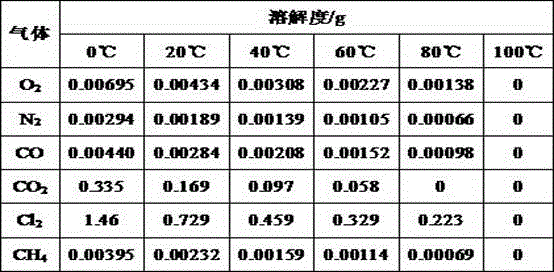

[0032] (1) Preheating: put 2m under normal pressure 3 The demineralized water in the demineralized water tank is heated to 100°C for 15 minutes to dissolve Ar and N in the water 2 , CO, CO 2 、CH 4 and Cl 2 remove all;

[0033] (2) Pressure maintenance: Introduce high-purity oxygen into the demineralized water tank preheated in step (1) to maintain pressure. The pressure is 0.3MPa. Oxygen's pressure-holding effect, avoiding Ar, N in the air 2 , CO, CO 2 、CH 4 and Cl 2 Dissolve again in demineralized water.

[0034] (3) Electrolysis: The demineralized water cooled to 30°C in step (2) is passed into the water electrolysis hydrogen production device for electrolysis to produce electrolytic hydrogen. After testing, there are impurities such as water and carbon dioxide in it.

[0035] (4) Catalytic deoxygenation: The electrolyt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com