Dynamic variable procedure ferrite rolling method based on endless rolling

An endless rolling, ferritic technology, applied in metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of limited production capacity, free switching of conventional austenite rolling, etc., to improve the surface quality , Improve the economic benefit of the enterprise and reduce the effect of the temperature rise of the roll

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

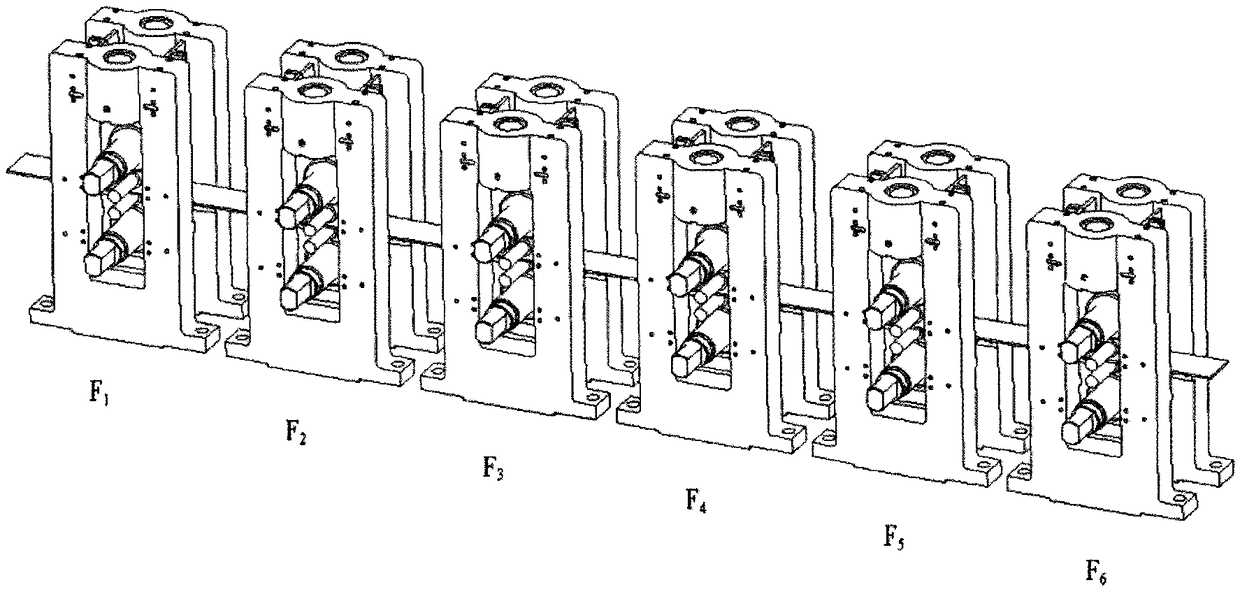

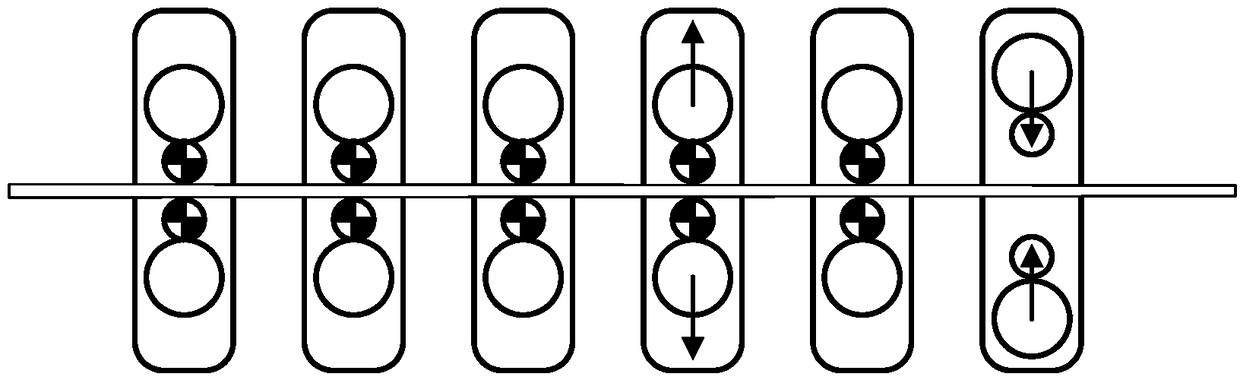

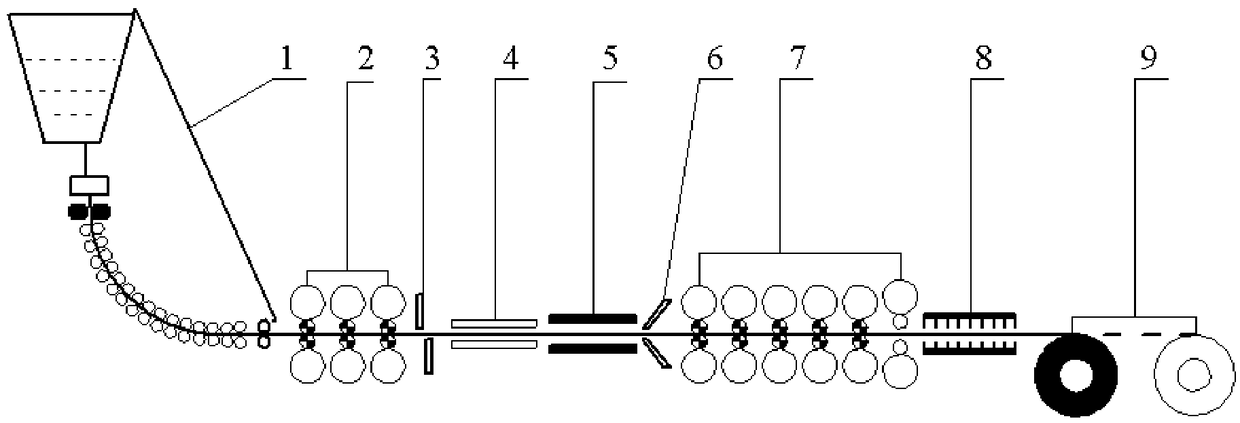

[0042] In the first embodiment of the present invention, a method of ferrite rolling based on the dynamic variable schedule of endless rolling of the present invention, when performing conventional endless austenitic rolling in endless rolling, the The strip, the exit temperature of the strip passing through the third stand of the rough rolling unit is 930°C, and the temperature is raised to 1050°C by induction heating, the cooling channel is not opened, and the microstructure of the strip is austenite before entering the finish rolling unit. Rolling by the finishing mill, the temperature of the last stand of the finishing mill is 840°C, and the temperature of the laminar flow cooling channel drops to 610°C. frame, the microstructure is austenitic, and austenitic rolling is carried out. When the rolls of the finishing rolling mill are worn out, the dynamic variable-schedule downstream adjustment or counter-current adjustment is adopted to change the rolls online without stoppi...

Embodiment 2

[0045]In the second embodiment of the present invention, a ferrite rolling method based on endless rolling dynamic variable schedule of the present invention, when conventional endless austenitic rolling is carried out in endless rolling, through continuous casting For the strip at 1500°C, the outlet temperature of the strip passing through the third stand of the rough rolling unit is 950°C, and the temperature is raised to 1100°C by induction heating, the cooling channel is not opened, and the microstructure of the strip is austenite before entering the finish rolling unit , enter the finishing rolling unit for rolling, and finally the strip passes through the finishing rolling unit with a temperature of 860°C at the end stand, and the temperature drops to 630°C after being cooled in the laminar flow cooling channel. The final stand of the unit has an austenitic microstructure and is subjected to austenitic rolling. When the rolls of the finish rolling unit are worn, the dyna...

Embodiment 3

[0048] In the third embodiment of the present invention, a method of ferrite rolling based on dynamic variable schedule of endless rolling of the present invention, when conventional austenitic rolling is performed in endless rolling, after continuous casting at 1500°C Strip, the exit temperature of the strip through the third stand of the rough rolling unit is 970°C, and the temperature is raised to 1150°C by induction heating, the cooling channel is not opened, the microstructure of the strip is austenite before entering the finishing Rolling in the rolling mill, the temperature of the strip at the end stand of the finishing mill is 880°C, and the temperature in the laminar flow cooling channel drops to 650°C. The microstructure is austenitic, and austenitic rolling is performed. When the rolls of the finishing rolling mill are worn out, the dynamic variable-schedule downstream adjustment or counter-current adjustment is adopted to change the rolls online without stopping th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com