Method for producing MnO through reducing roasting of MnO ore by utilizing wood chips

A technology of manganese oxide and manganese monoxide, which is applied in the fields of metallurgy and chemical industry, can solve the problems of high equipment operation and maintenance costs, high production energy consumption, etc., and achieve the effects of high equipment operation and maintenance costs, high production energy consumption, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

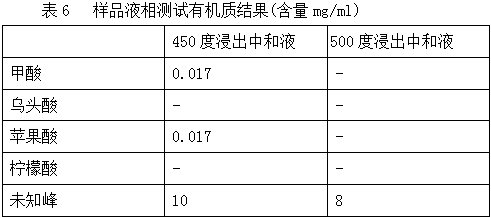

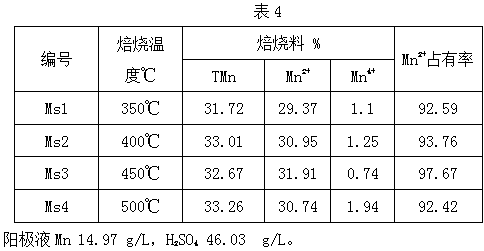

Examples

Embodiment 1

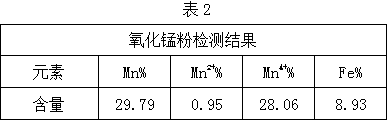

[0022] A method for producing manganese monoxide by reducing and roasting manganese oxide ore with sawdust, comprising the following steps:

[0023] (1) manganese oxide ore and sawdust are pulverized respectively through 10 mesh sieves; described manganese oxide ore is pyrolusite; the weight percentage of moisture in the described sawdust is 15%;

[0024] (2) Mix the pulverized manganese oxide ore and wood chips evenly to obtain a mixed material, and the amount of wood chips is 30% of the weight of the manganese oxide ore;

[0025] (3) Put the mixed material into the rotary roasting kiln and roast at 300°C for 70 minutes,

[0026] The roasted material enters the cooling kiln through the unloading device, and is cooled to within 100°C in an air-isolated environment to obtain the roasted material containing MnO.

Embodiment 2

[0028] A method for producing manganese monoxide by reducing and roasting manganese oxide ore with sawdust, comprising the following steps:

[0029] (1) manganese oxide ore and sawdust are pulverized respectively through a 50 mesh sieve; described manganese oxide ore is manganese ore and black manganese ore; the weight percentage of moisture in the described sawdust is 24%;

[0030] (2) Mix the pulverized manganese oxide ore and wood chips evenly to obtain a mixed material, and the amount of wood chips is 34% of the weight of the manganese oxide ore;

[0031] (3) Put the mixed material into the rotary roasting kiln and roast at 400°C for 60 minutes,

[0032] The roasted material enters the cooling kiln through the unloading device, and is cooled to within 100°C in an air-isolated environment to obtain the roasted material containing MnO.

Embodiment 3

[0034] A method for producing manganese monoxide by reducing and roasting manganese oxide ore with sawdust, comprising the following steps:

[0035] (1) manganese oxide ore and sawdust are pulverized respectively through 100 mesh sieves; described manganese oxide ore is brown manganese ore, hydromanganese ore and metamanganate; the weight percentage of moisture in the described sawdust is 30%;

[0036] (2) Mix the pulverized manganese oxide ore and wood chips evenly to obtain a mixed material, and the amount of wood chips is 36% of the weight of the manganese oxide ore;

[0037] (3) Put the mixed material into the rotary roasting kiln and roast at 500°C for 45 minutes,

[0038] The roasted material enters the cooling kiln through the unloading device, and is cooled to within 100°C in an air-isolated environment to obtain the roasted material containing MnO.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com