Method for continuous production of N-methylisopropanolamine

A technology of methyl isopropanolamine and monomethylamine, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of amino hydroxyl compounds, etc., and can solve problems such as the inability to meet the demand for N-methyl isopropanolamine , to achieve the effect of saving manpower, low production cost and improving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

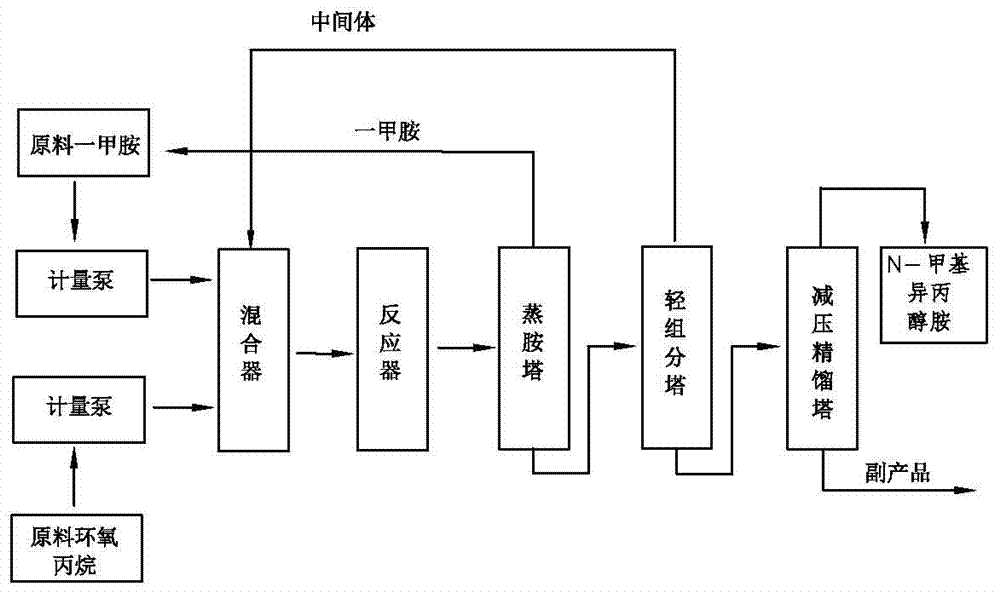

[0027] A method for the continuous production of N-methylisopropanolamine in the present embodiment, such as figure 1 shown, including the following steps:

[0028] Step 1, feeding: feed propylene oxide and monomethylamine into the mixer respectively through a metering pump, wherein the molar ratio of propylene oxide to monomethylamine is 1:1.1;

[0029] Step 2, mixing: adjusting the temperature of the mixer to 10°C and the pressure to 3.5MPa, and mixing monomethylamine and propylene oxide in the mixer to obtain a uniformly mixed mixture;

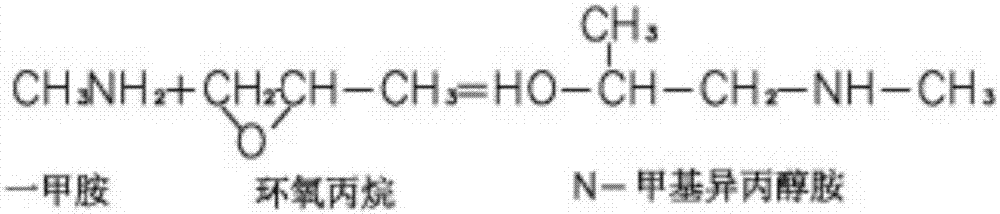

[0030] Step 3, reaction: pump the mixture obtained in step 2 into the reactor, then adjust the temperature of the reactor to 110°C, and the pressure to 3.5MPa, and allow the mixture to fully react in the reactor, the reaction time is 5min, Obtain the first crude product containing N-methylisopropanolamine; Wherein, the reaction formula of propylene oxide and monomethylamine is:

[0031]

[0032] Step 4, removing monomethylamine: the fi...

Embodiment 2

[0036] A method for the continuous production of N-methylisopropanolamine in the present embodiment, such as figure 1 shown, including the following steps:

[0037] Step 1, feeding: feed propylene oxide and monomethylamine into the mixer respectively through a metering pump, wherein the molar ratio of propylene oxide to monomethylamine is 1:1.3;

[0038] Step 2, mixing: adjusting the temperature of the mixer to 30°C and the pressure to 5.0MPa, and mixing monomethylamine and propylene oxide in the mixer to obtain a uniformly mixed mixture;

[0039] Step 3, reaction: continuously enter the mixture obtained in step 2 into the reactor, then adjust the temperature of the reactor to 130°C, and the pressure to 5.0MPa, and allow the mixture to fully react in the reactor, the reaction time is 2min, Obtain the first crude product containing N-methylisopropanolamine; Wherein, the reaction formula of propylene oxide and monomethylamine is:

[0040]

[0041] Step 4, removing monomethy...

Embodiment 3

[0045] A method for the continuous production of N-methylisopropanolamine in the present embodiment, such as figure 1 shown, including the following steps:

[0046] Step 1, feeding: feed propylene oxide and monomethylamine into the mixer respectively through a metering pump, wherein the molar ratio of propylene oxide to monomethylamine is 1:1.2;

[0047] Step 2, mixing: adjusting the temperature of the mixer to 15°C and the pressure to 4.0MPa, and mixing monomethylamine and propylene oxide in the mixer to obtain a uniformly mixed mixture;

[0048] Step 3, reaction: continuously enter the mixture obtained in step 2 into the reactor, then adjust the temperature of the reactor to 120°C, the pressure to 4.0MPa, and allow the mixture to fully react in the reactor, and the reaction time is 3.5min , obtain the first crude product containing N-methylisopropanolamine; Wherein, the reaction formula of propylene oxide and monomethylamine is:

[0049]

[0050] Step 4, removing monome...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com