Ultraviolet light-heat dual-curing primer for vacuum coating of vehicle headlight and application method

A dual-curing and vacuum coating technology, applied in coating, surface pretreatment, and devices for coating liquid on the surface, etc., can solve the problems of large internal stress, poor adhesion, unsatisfactory heat resistance, etc. The effect of bonding density, improving adhesion and reducing internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 Preparation of isocyanate-modified modified acrylic resin containing carbon-carbon double bond and hydroxyl group

[0027] Specific steps are as follows:

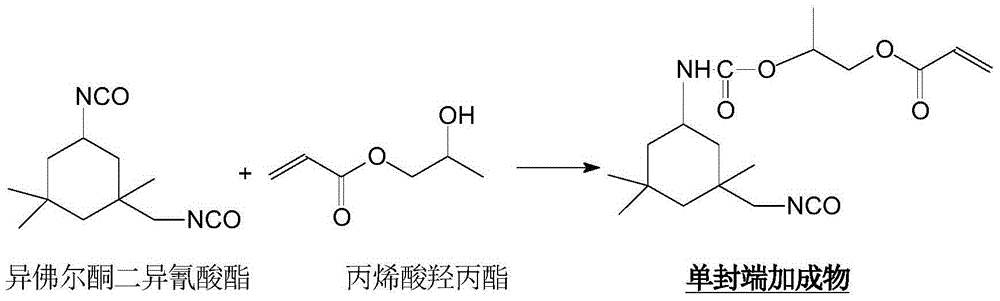

[0028] ① Synthesis of single-capped adducts

[0029] Add 55.5g of isophorone diisocyanate, 30g of dehydrated toluene, 0.1g of polymerization inhibitor p-hydroxyanisole, and 0.05g of catalyst dibutyltin dilaurate into the reaction flask, raise the temperature to 50°C, and start dropping 39g of hydroxypropyl acrylate The mixture of ester and 64.5g dehydrated toluene was added dropwise in 1 hour, kept at 50°C for 2 hours, raised to 60°C for 1 hour, continued to heat up to 70°C for 1 hour, added 0.05g of catalyst dibutyltin dilaurate and raised to 80°C After keeping warm for 1 hour, cool down to below 50°C, and the product is a single-capped adduct, which is stored for future use;

[0030] The reaction formula involved in the above synthesis is as follows:

[0031]

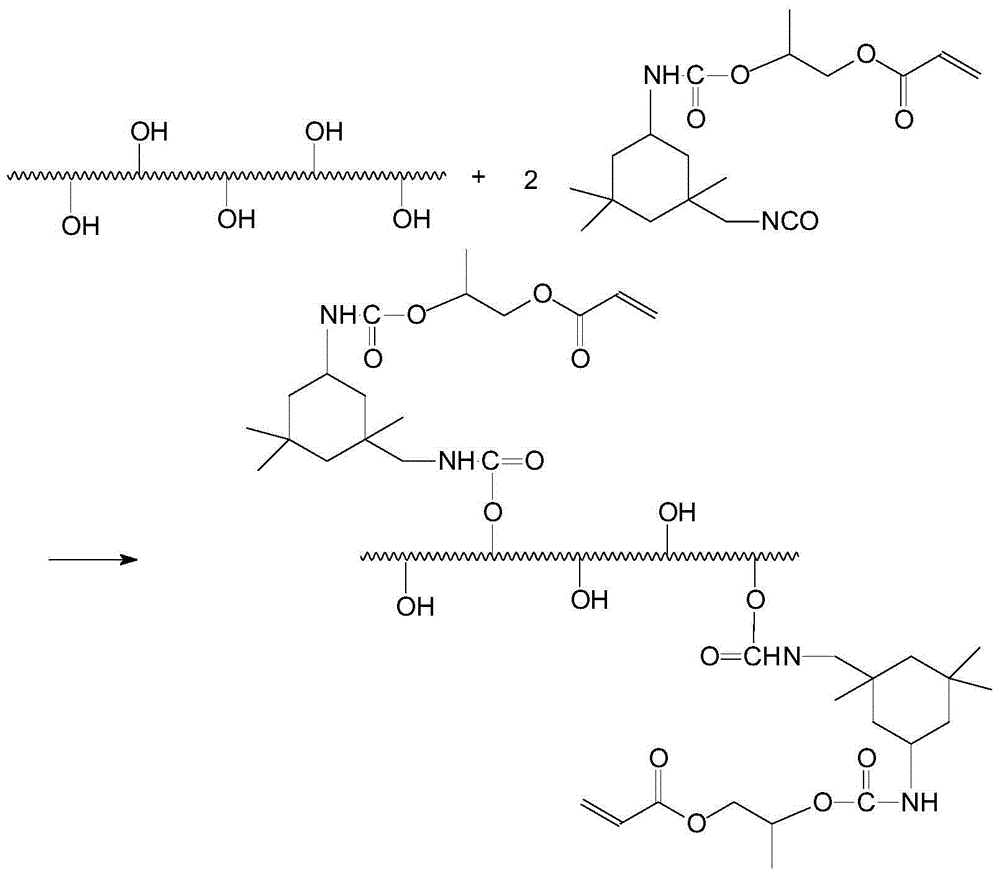

[0032] ② Synthesis of isocyanate-modif...

Embodiment 2

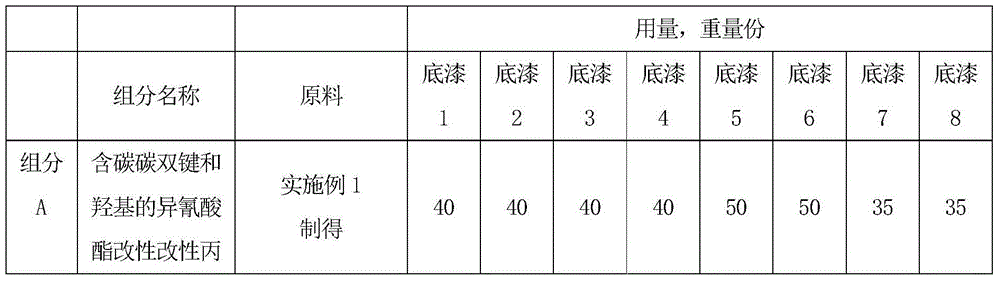

[0037] Example 2 Preparation of UV-heat dual curing primers 1-8

[0038] The ultraviolet-heat dual curing primer of the present invention is composed of component A and component B, and the component A is composed of 35 to 70 parts by weight of isocyanate-modified acrylic resin containing carbon-carbon double bonds and hydroxyl groups, and containing carbon-carbon double bonds 5-20 parts by weight of oligomers, 10-50 parts by weight of compounds containing at least 2 (meth)acryloyl groups, 2-5 parts by weight of photoinitiators, 10-40 parts by weight of solvents, organic silicon or fluorocarbon The leveling agent is composed of 0.1 to 3 parts by weight, and the sum of the above components is 100 parts by weight;

[0039] ① See Table 1 for the specific formulations of primers 1-8.

[0040] Table 1

[0041]

[0042]

[0043] Note 1: The total of each component A of primers 1 to 8 is 100 parts by weight; The molar ratio of -NCO groups contained in the polyfunctional isoc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com