Environment-friendly pervious concrete for roads as well as preparation method and application thereof

A permeable concrete and environmentally friendly technology, applied in the field of concrete, can solve the problems of polluting surrounding water sources, affecting vegetation growth, occupying land, etc., and achieves the effects of light weight, low cost and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The raw material composition of solid waste-based sulfoaluminate cementitious material: 38 parts of waste rock powder, 17 parts of desulfurized gypsum, 12 parts of steel slag, and 33 parts of aluminum slag.

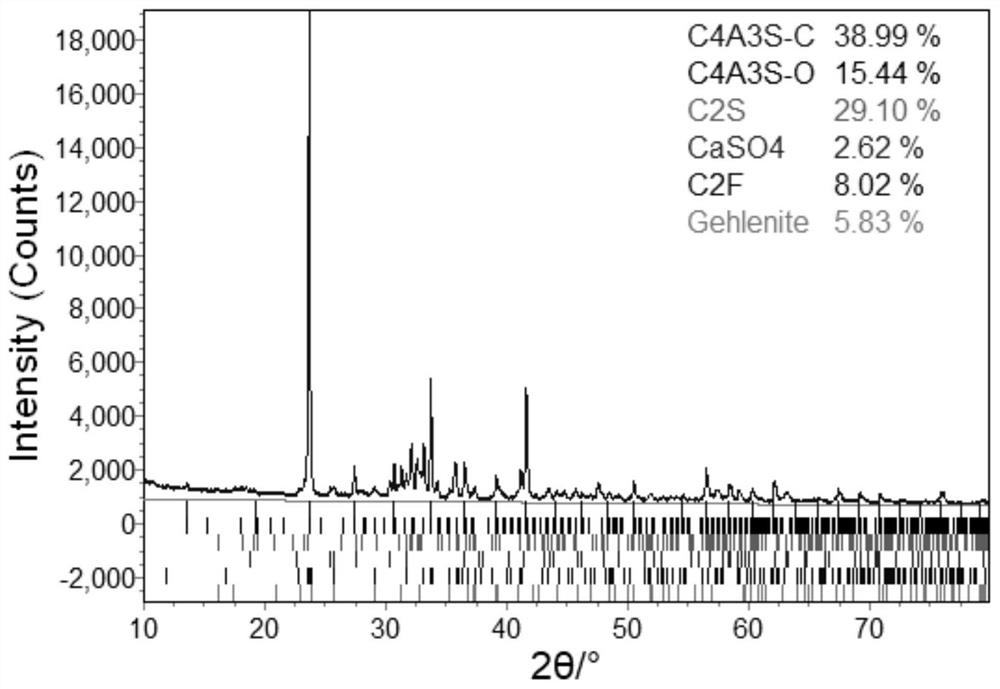

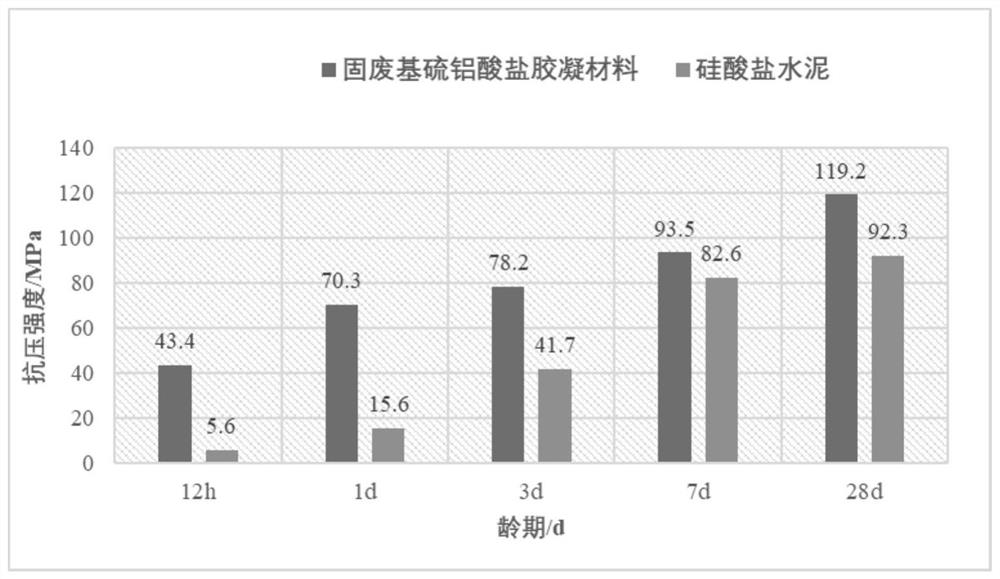

[0040] Take waste rock powder, desulfurized gypsum, steel slag, and aluminum slag and mix them in proportion, then calcinate and keep warm at 1250°C for 30 minutes in a rotary kiln to obtain cement clinker. Take 90 parts of the cement clinker, mix it with 4 parts of limestone powder and 6 parts of gypsum, and grind it finely. Compared with ordinary Portland cement (P.O) on the market, it has the characteristics of early strength, rapid hardening, high strength, low cost, and environmental protection. Among them, the quantitative analysis of minerals contained in the XRD spectrum of solid waste-based sulfoaluminate cementitious materials is as follows: figure 1 As shown, its compressive strength from 12h to 28d is as figure 2 shown.

Embodiment 2

[0043] Raw material composition of permeable pavement concrete: 200 parts of solid waste-based sulfoaluminate cementitious material, 760 parts of coarse aggregate, 40 parts of fine aggregate, 10 parts of waste rock powder, 0.2 part of water reducer, 1 part of thickener; than 0.21.

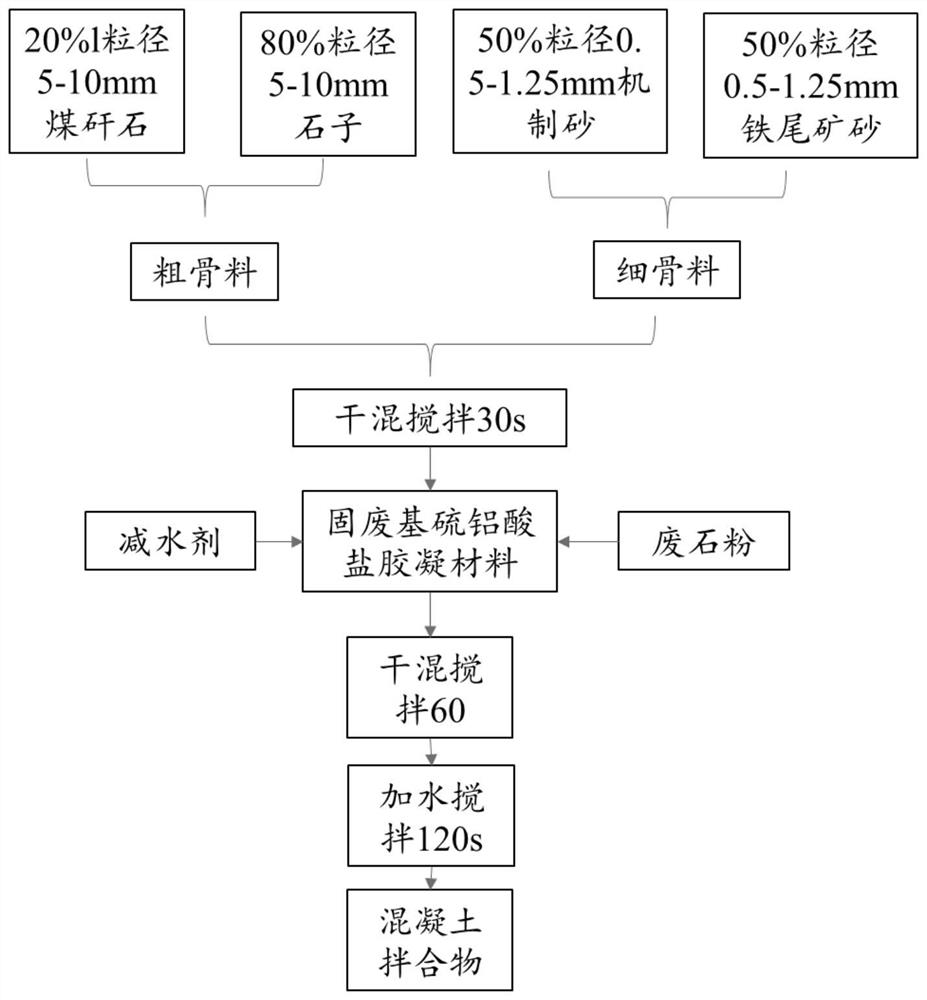

[0044] Coarse aggregate mixture of crushed stones and coal gangue particles with a mass ratio of 8:2 with a particle size of 5mm-10mm and machine-made sand and iron tailings with a mass ratio of 1:1 with a particle size of 0.5mm-1.25mm The fine aggregate mixture was placed in a mixer and stirred for 30s. Then add solid waste-based sulfoaluminate cementitious material, waste rock powder, water reducer, and thickener for dry mixing for 60 seconds, and finally add water and stir for 120 seconds to obtain a permeable concrete mixture for pavement. The concrete is placed in the mold and compacted to shape, then the standard curing temperature is 20±0.5°C and the humidity is 98%.

[0045] Performance t...

Embodiment 3

[0047] Raw material composition of permeable pavement concrete: 200 parts of solid waste-based sulfoaluminate cementitious material, 730 parts of coarse aggregate, 60 parts of fine aggregate, 12 parts of waste rock powder, 0.2 part of water reducer, 1 part of thickener; water glue than 0.21.

[0048] Coarse aggregate mixture of crushed stones and coal gangue particles with a mass ratio of 8:2 with a particle size of 5mm-10mm and machine-made sand and iron tailings with a mass ratio of 1:1 with a particle size of 0.5mm-1.25mm The fine aggregate mixture was placed in a mixer and stirred for 30s. Then add solid waste-based sulfoaluminate cementitious material, waste rock powder, water reducer, and thickener for dry mixing for 60 seconds, and finally add water and stir for 120 seconds to obtain a permeable concrete mixture for pavement. The concrete is placed in the mold and compacted to shape, then the standard curing temperature is 20±0.5°C and the humidity is 98%.

[0049] Pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com