System for producing 3.5-valent high-purity vanadium electrolyte and method thereof

An electrolyte and high-purity technology, used in acidic electrolytes, aqueous electrolytes, regenerative fuel cells, etc., can solve the problems of affecting charge and discharge efficiency, low purity, electrolyte aging, etc., and achieve the effect of convenient configuration and use, and high activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

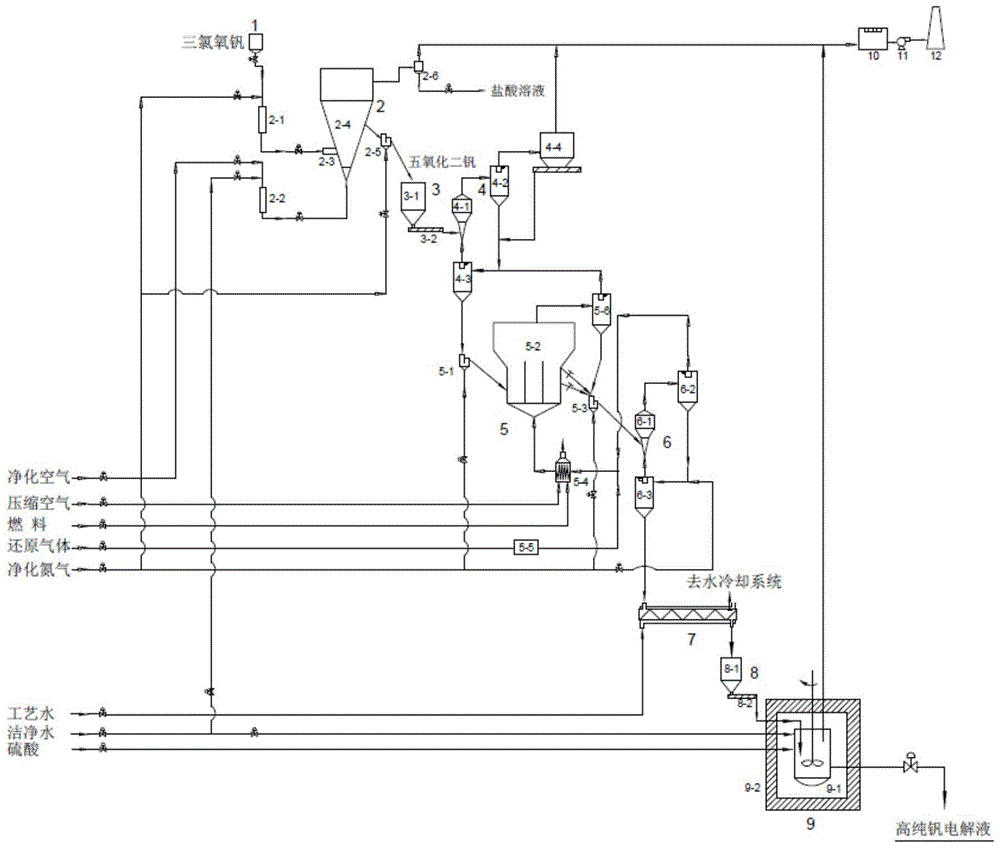

[0072] to combine figure 1 , the system used in the present embodiment to produce 3.5 valence high-purity vanadium electrolytes includes a vanadyl trichloride storage tank 1, a gas phase hydrolysis fluidized bed 2, a vanadium pentoxide feeding device 3, a preheating dust removal device 4, and a reducing flow chemical bed 5, primary cooling device 6, secondary cooling device 7, low-priced vanadium oxide feeding device 8, dissolving and activating device 9, tail gas washing absorption tower 10, induced draft fan 11 and chimney 12;

[0073] The gas-phase hydrolysis fluidized bed 2 includes a vanadyl trichloride vaporizer 2-1, a clean water vaporizer 2-2, a chloride spray gun 2-3, a gas-phase hydrolysis fluidized bed main body 2-4, and a hydrolysis fluidized bed discharger 2 -5. Hydrochloric acid tail gas absorber 2-6;

[0074] The vanadium pentoxide feeding device 3 comprises a vanadium pentoxide feed bin 3-1 and a vanadium pentoxide screw feeder 3-2;

[0075] The preheating an...

Embodiment 2

[0090]In this embodiment, the above-mentioned system is used to produce a 3.5-valent high-purity vanadium electrolyte. The specific method includes the following steps: the vanadyl trichloride in the vanadyl trichloride storage tank 1 and the nitrogen from the nitrogen purification main pipe pass through the oxytrichloride After vanadium vaporizer 2-1 is vaporized and preheated, it enters the main body 2-4 of the gas phase hydrolysis fluidized bed through the chloride spray gun 2-3; clean water and purified air are vaporized and preheated by the clean water vaporizer 2-2 and sent to into the main body 2-4 of the gas-phase hydrolysis fluidized bed to hydrolyze vanadium oxychloride and maintain the fluidization of the powder material to form vanadium pentoxide powder and hydrolysis flue gas rich in hydrogen chloride; The vanadium powder is discharged into the vanadium pentoxide silo 3-1 through the hydrolysis fluidized bed discharger 2-5; the hydrolysis flue gas is expanded throu...

Embodiment 3

[0094] In this embodiment, vanadyl chloride (more than 2N in purity) is used as raw material, and the processing capacity is 3kg / h. In the vanadyl chloride vaporizer 2-1, the vaporization operating temperature is 40° C., and the molar ratio of nitrogen to vanadyl chloride is 10:1; in the clean water vaporizer 2-2, the vaporization operating temperature is 40°C, and the mass ratio of air to water is 10:1; in the gas phase hydrolysis fluidized bed main body 2-4, water vapor and The mass ratio of vanadium oxychloride is 10:1, the operating temperature of gas phase hydrolysis is 100°C, and the average residence time of the powder is 300min; obtain vanadium pentoxide; in reducing fluidized bed 5, pass into bed body 5-2 The reducing gas is hydrogen, and the hydrogen gas fraction in the mixed gas of nitrogen and hydrogen in the bed body 5-2 is 10%, the average residence time of the powder is 90min, and the operating temperature of the reducing fluidized bed is 400°C; A low-valent van...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com