Titanium tetrachloride refining processing technology

A technology of titanium tetrachloride, refining and processing, applied in the direction of titanium halide and other directions, can solve the problem of difficult processing technology and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Titanium tetrachloride is an inorganic compound with the chemical formula TiCl4, and is an important intermediate in the production of titanium metal and its compounds. At room temperature, titanium tetrachloride is a colorless liquid, and fumes in the air to generate solid titanium dioxide and hydrochloric acid droplets. Titanium tetrachloride is divided into crude titanium tetrachloride and refined titanium tetrachloride, and refined titanium tetrachloride is obtained by processing crude titanium tetrachloride.

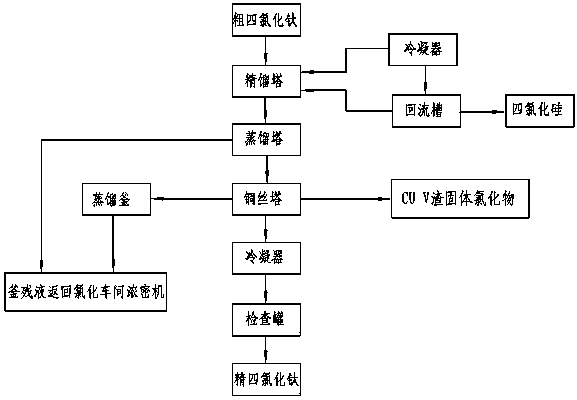

[0012] Such as figure 1 As shown, the present invention provides a kind of processing method that thick titanium tetrachloride is processed into refined titanium tetrachloride, namely: first remove high-boiling point impurities by distillation, then remove low-boiling point impurities by rectification, and remove vanadium by copper wire , Preparation of refined titanium tetrachloride.

[0013] The refining process of titanium tetrachloride is as follows:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com