Preparation method of vanadium oxytrichloride

A vanadium oxychloride and vanadium source technology, applied in the field of materials, can solve the problems of toxic and harmful substances, personal and environmental hazards, etc., and achieve the effects of low toxicity, strong shape controllability, simple and reliable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment discloses a kind of preparation method of vanadyl trichloride, comprising the following steps:

[0041] 1. Weigh 50gV 2 o 5 , add 200mL of secondary water, stir at a speed of 200rpm, and mechanically stir until the reaction system is uniform.

[0042] 2. Add 72.61g of diammonium hydrogen phosphate while stirring, so that the ratio of vanadium to phosphorus in the solution is 1:1.

[0043] 3. Under the condition of continuous stirring, rapidly raise the temperature of the reaction system to 80°C, the heating rate is 7°C / min, and react for 20min until the reaction system is in the form of slurry.

[0044] 4. The obtained sample was dried in a blast drying oven at a drying temperature of 60° C. and a drying time of 8 hours until the sample turned into a yellow powder with a water content of less than 5% wt.

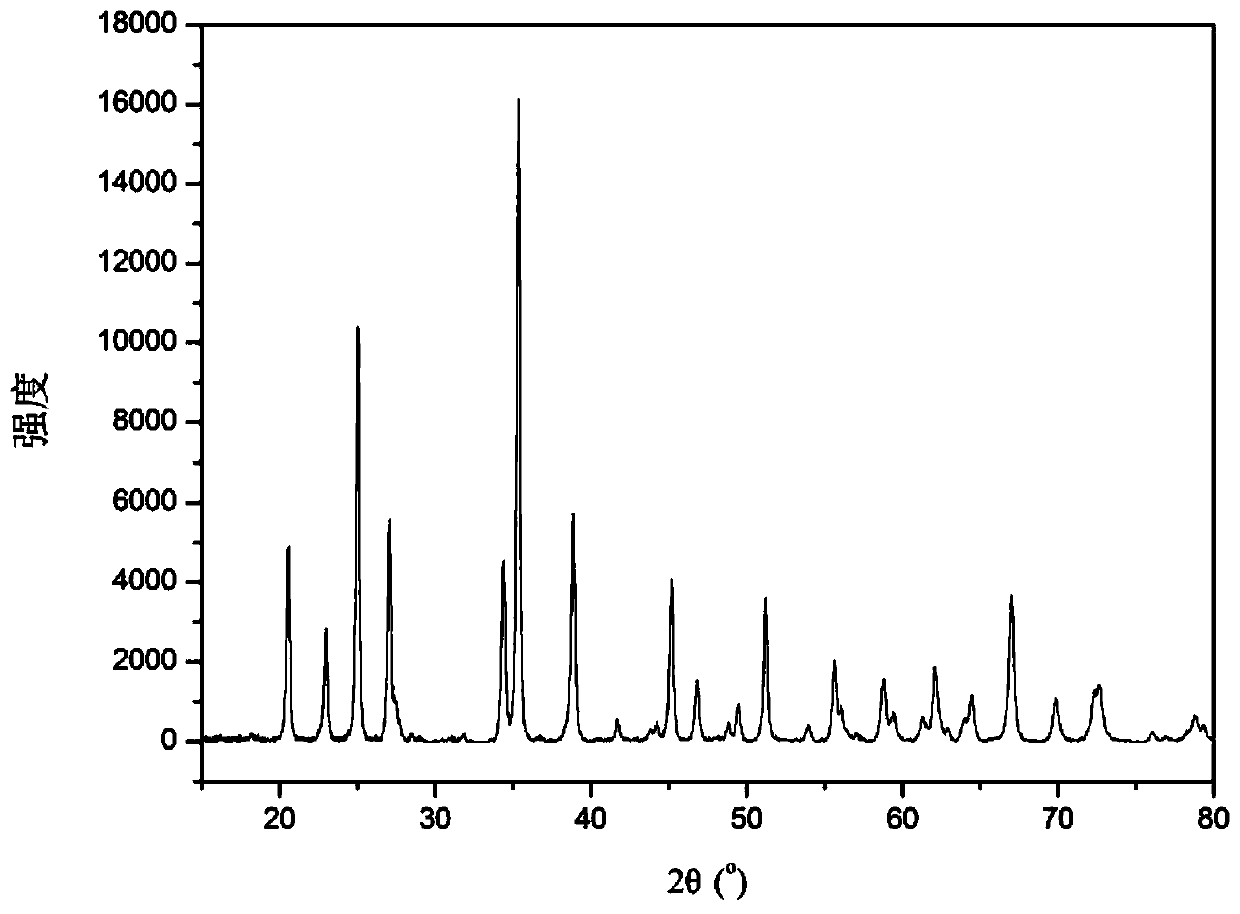

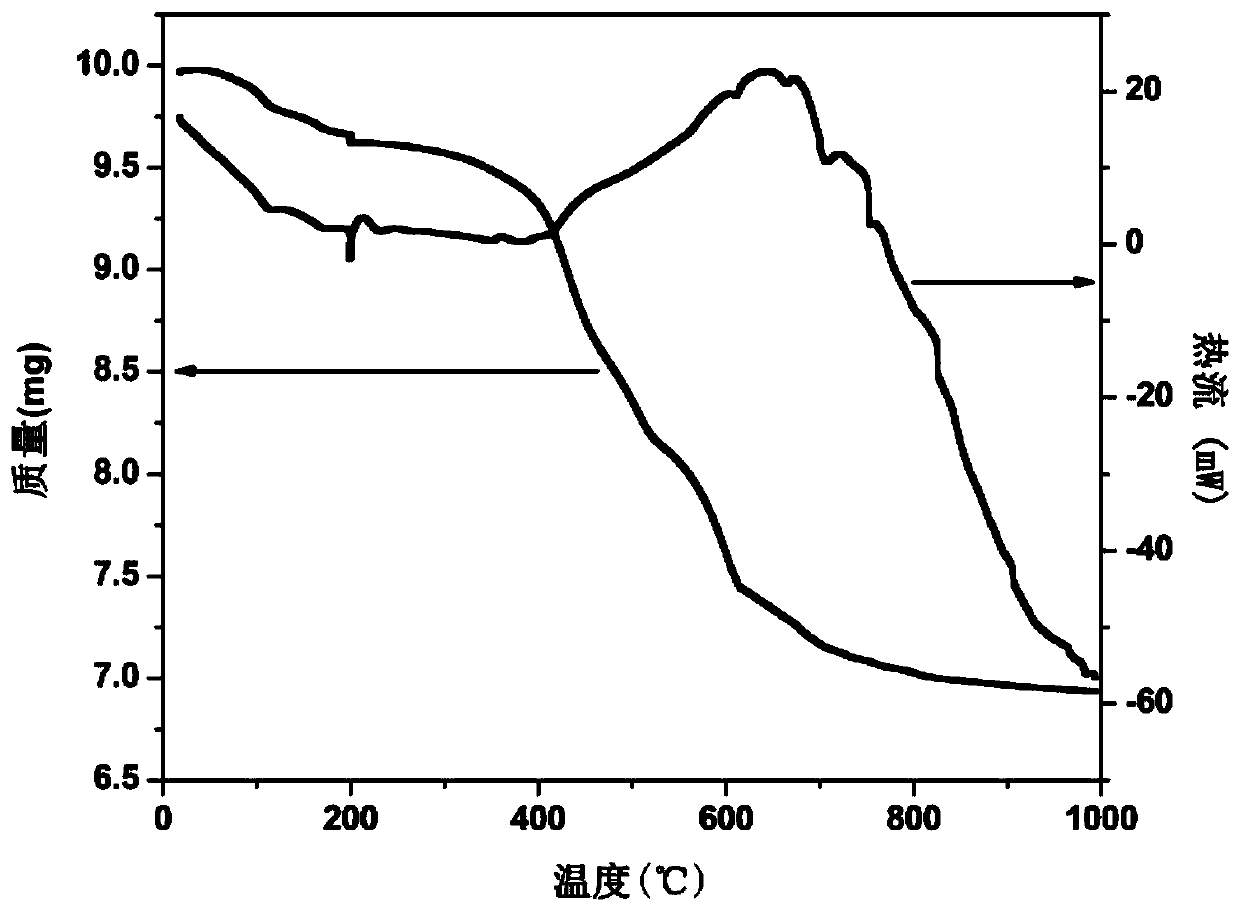

[0045] 5. After drying, use a powder machine to pulverize the sample, pass the pulverized sample through a sieve of more than 200 mesh, and place i...

Embodiment 2

[0055] 1. Put vanadium source V 2 o 5 After grinding, it is ground with aluminum chloride so that the molar ratio of vanadium to chloride is 1:1.

[0056] 2. Place the obtained sample in a tube furnace, use an inert non-oxidizing atmosphere to replace the atmosphere in the tube, and roast it under the conditions of an inert non-oxidizing atmosphere (nitrogen, argon). The roasting temperature is 600 ° C, and the roasting time is 40 minutes. The tailpipe distillate is the target product vanadyl trichloride.

Embodiment 3

[0058] 1. Grind the vanadium source APV and mix it with magnesium chloride, and grind and mix evenly so that the molar ratio of vanadium to chloride is 3:4.

[0059] 2. Place the obtained sample in a tube furnace, use an inert non-oxidizing atmosphere to replace the atmosphere in the tube, and roast it under the conditions of an inert non-oxidizing atmosphere (nitrogen, argon). The roasting temperature is 700 ° C, and the roasting time is 30 minutes. The tailpipe distillate is the target product vanadyl trichloride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com