System and method for high-value comprehensive utilization of high-chromium vanadium slag

A high-chromium, high-value technology, applied in the chemical and metallurgical fields, can solve the problems of lack of high-value utilization of vanadium, chromium process technology, lack of efficient cleaning, and low recovery rate of vanadium.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

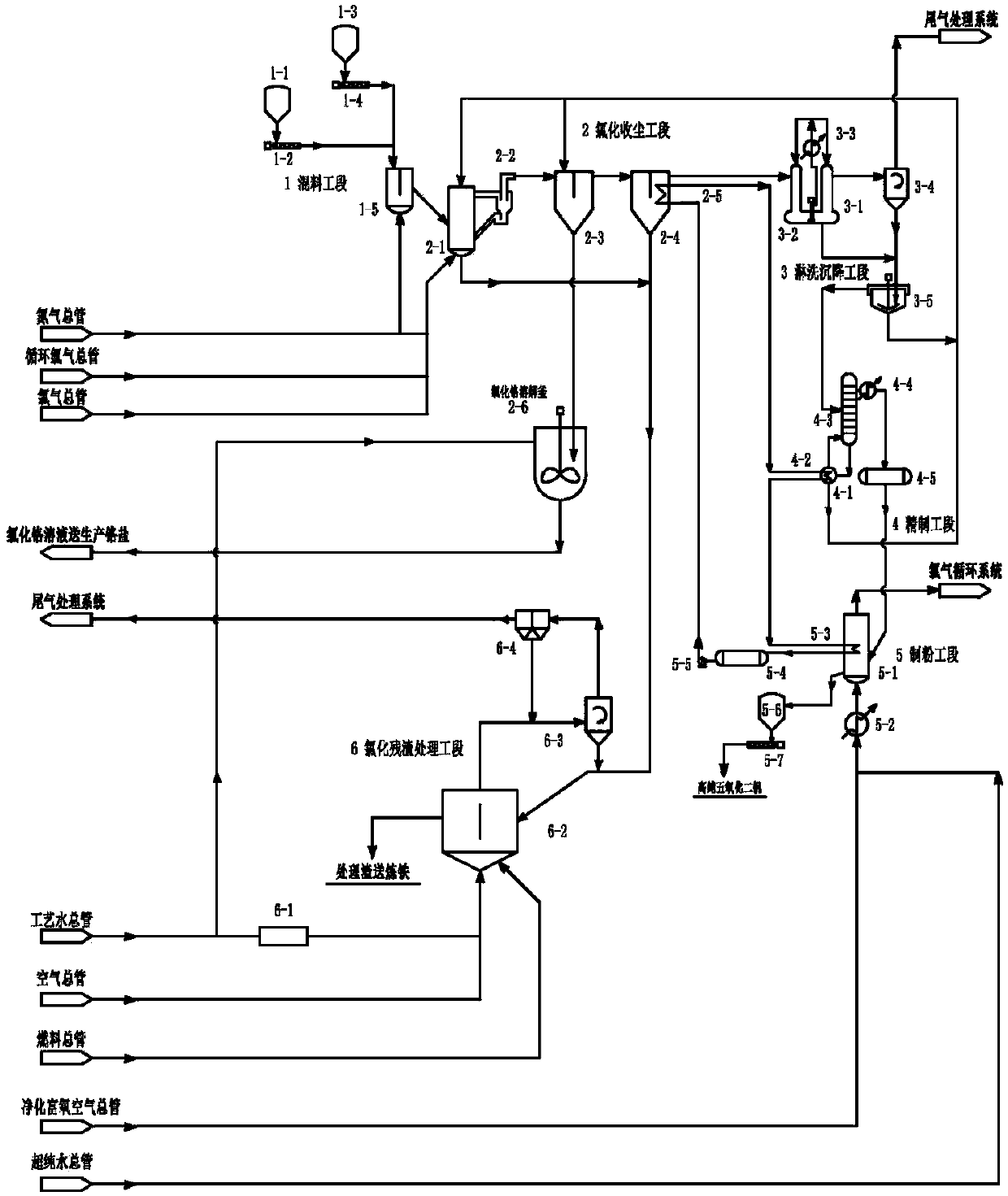

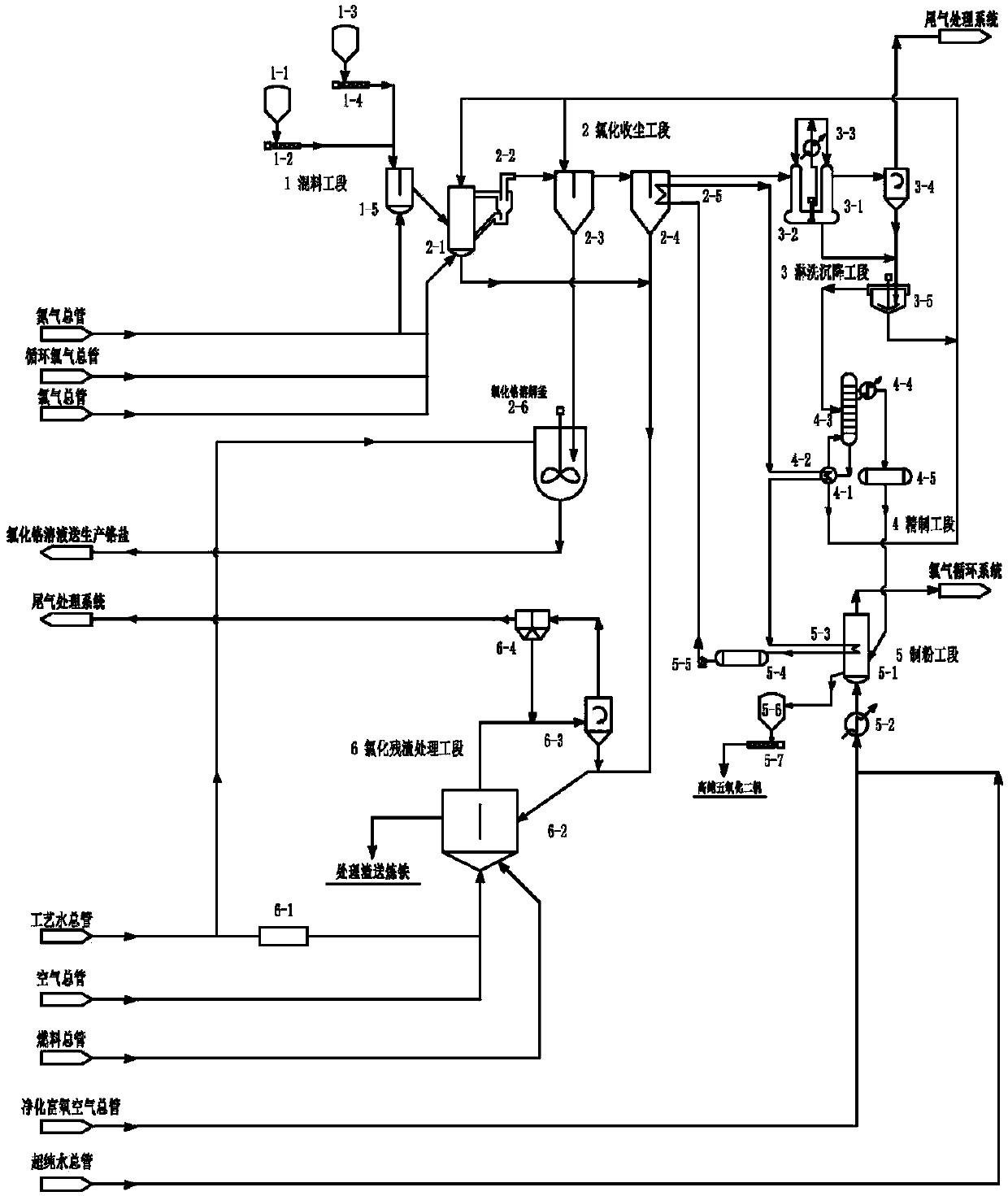

[0064] to combine figure 1 , a system for high-value comprehensive utilization of high-chromium vanadium slag used in this embodiment, including mixing section 1, chlorination and dust collection section 2, leaching and sedimentation section 3, refining section 4, milling section 5 and Chlorination residue treatment section 6;

[0065] Mixing section 1 includes high chromium vanadium slag silo 1-1, high chromium vanadium slag screw feeder 1-2, carbon source silo 1-3, carbon source screw feeder 1-4 and fluidized bed Mixer 1-5;

[0066] Chlorination dust collection section 2 includes circulating fluidized bed main body 2-1, circulating fluidized bed cyclone separator 2-2, primary dust collection tower 2-3, secondary dust collection tower 2-4, dust collection tower heat exchange Device 2-5 and chromium chloride dissolution kettle 2-6;

[0067] The leaching and settling section 3 includes a leaching tower 3-1, a slurry pump 3-2, a leaching tower heat exchanger 3-3, a drip catch...

Embodiment 2

[0076] Using the system described in Embodiment 1, this embodiment provides a method for comprehensive utilization of high-value vanadium slag, and the method includes the following steps:

[0077] The high chromium vanadium slag in the high chromium vanadium slag silo 1-1 enters the fluidized bed mixer 1-5 through the high chromium vanadium slag screw feeder 1-2; the carbon source silo 1-3 The carbon source enters in the fluidized bed mixer 1-5 through the carbon source screw feeder 1-4; The high-chromium vanadium slag is evenly mixed and enters the circulating fluidized bed main body 2-1 together; the nitrogen gas from the nitrogen main pipe, the chlorine gas from the circulating chlorine gas main pipe, and the chlorine gas from the chlorine gas main pipe enter from the air inlet at the bottom of the circulating fluidized bed main body 2-1 ; While maintaining the fluidization of high-chromium vanadium slag and carbon source, a chlorination reaction occurs with it; the chlori...

Embodiment 3

[0080]In this embodiment, high-chromium vanadium slag is used as the raw material, wherein the mass fraction of vanadium pentoxide is 8%, and the mass fraction of chromium oxide is 6%. The processing capacity is 400kg / h, and the chromium chloride aqueous solution and high-purity vanadium pentoxide are prepared through processes such as mixing, chlorination in a circulating fluidized bed, grading dust collection, leaching and sedimentation, refining, and pulverizing, and the waste heat is utilized. , Residue treatment to achieve industrial waste energy utilization and residue dechlorination treatment.

[0081] In the fluidized bed mixer 1-5, the amount of metallurgical coke added is 5% of the mass of the high-chromium vanadium slag; the chlorination temperature of the circulating fluidized bed is 500°C, and the operating gas velocity of the circulating fluidized bed is 0.04m / s, the mole fraction of chlorine in the chlorine-nitrogen mixture entering the air chamber is 15%, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com