Recovery method and equipment of vanadium-containing slurry produced from titanic chloride refining process

A technology of titanium tetrachloride and refining process is applied in the field of treatment and recovery of vanadium-containing mud, which can solve the problems of failure to achieve vanadium, separation of titanium, consumption of large energy, and enrichment of vanadium content, saving construction investment and energy. The effect of reducing energy consumption, reducing pollution and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

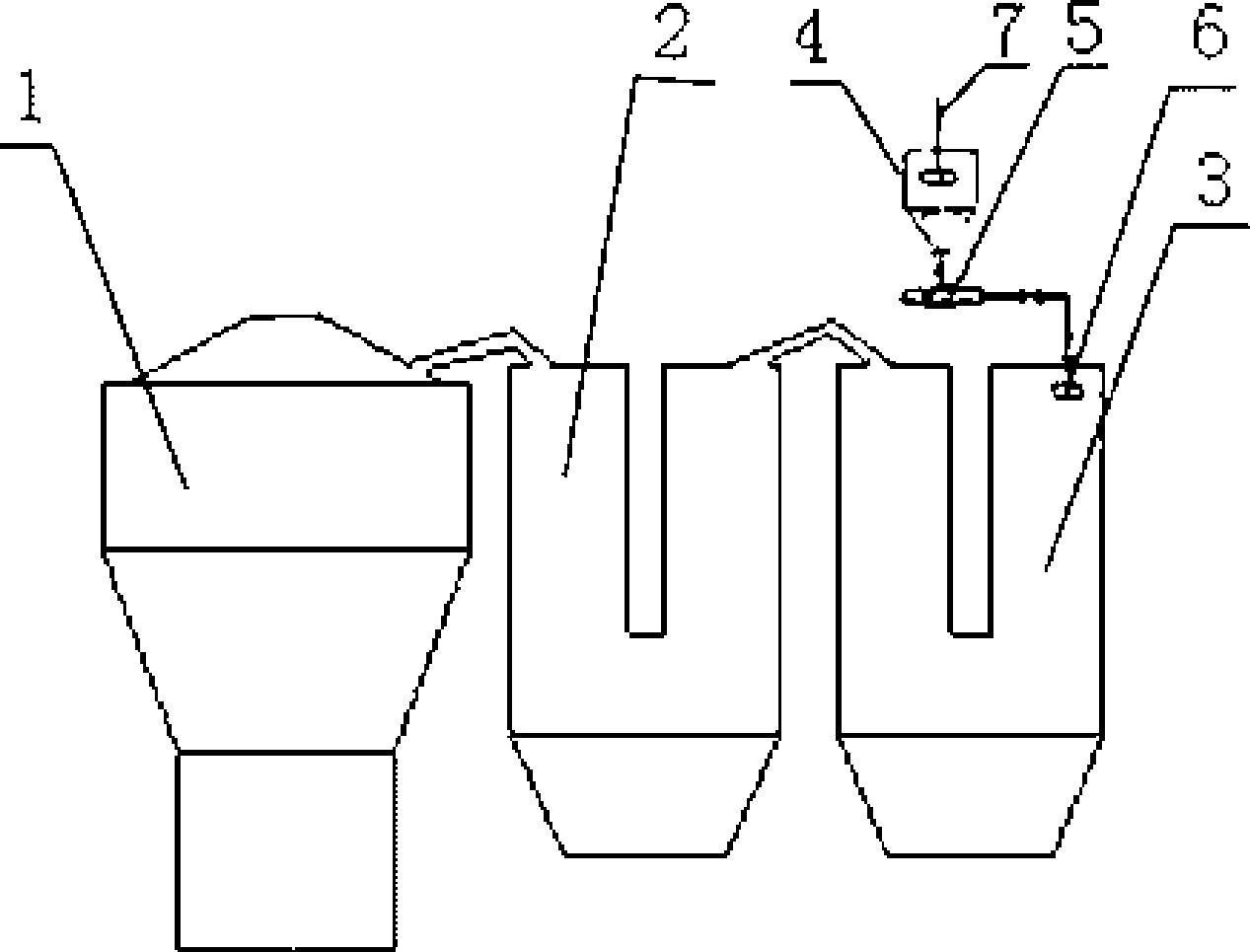

[0012] Preferred embodiment of the present invention: process vanadium-containing mud, spray the vanadium-containing mud produced in the refining process into the chlorination system, and control the temperature of the injection point at 150-190°C to make the vanadium oxychloride in the vanadium-containing mud Exhaust the system in solid form from the bottom of the dust collector. The vanadium-containing mud can be sprayed into the second-stage gravity dust collector. The temperature of the second-stage gravity dust collector is 150-180°C, which meets the temperature requirements for separation and recovery of titanium tetrachloride.

[0013] The present invention also provides a kind of equipment that implements the recovery method of the vanadium-containing mud generated in the refining process of titanium tetrachloride, the equipment includes a chlorination furnace 1, a first-stage gravity dust collector 2 and a second-stage gravity dust collector 3. A vanadium-containing m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com