Integrated filtering material, preparation method and applications thereof

A filter material and catalyst technology, applied in chemical instruments and methods, separation methods, filtration and separation, etc., can solve the problems of low catalyst loading intensity, poor pollutant treatment effect, and uncontrollable loading amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

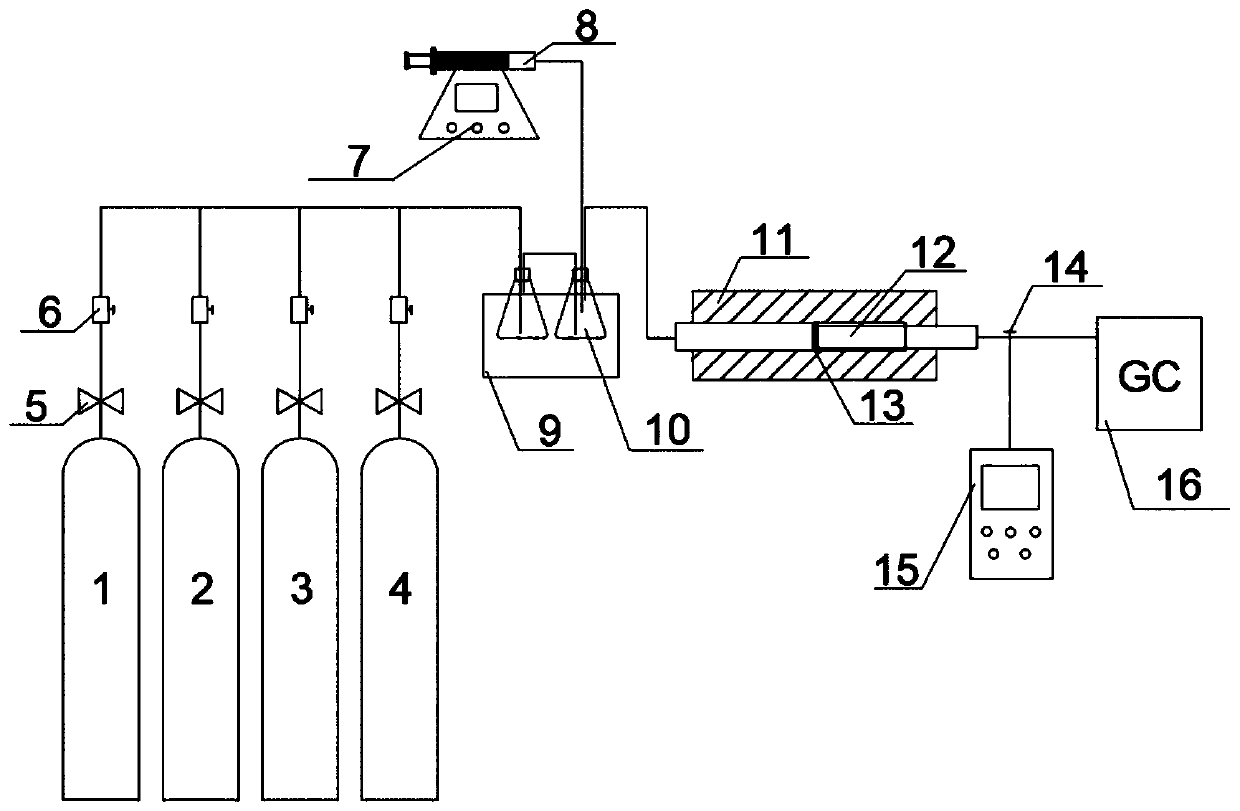

Method used

Image

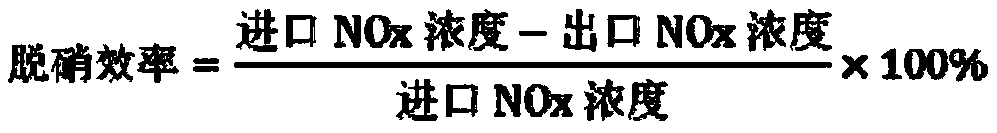

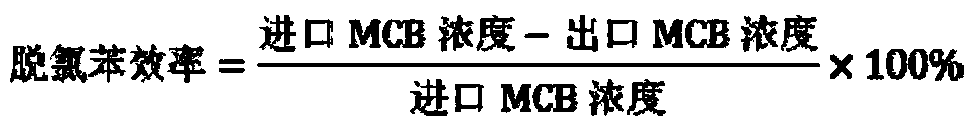

Examples

Embodiment 1

[0044] a. Take the P84 filter material cut into a disc with a diameter of 30mm and completely immerse it in an aqueous solution of 1% alkyl glycoside APG0814, stir for 2 hours, and dry it in a blast drying oven at 110°C for 6 hours to obtain a filter material modified by alkyl glycoside .

[0045] b. Add distilled water dropwise on the filter material treated in step a until the filter material is completely soaked, and determine that the saturated water absorption of the filter material with a diameter of 30 mm is 1.7 mL.

[0046] c. In order to obtain Mn: Ce = 4: 1, MnO 2 and CeO 2 The loading capacity is 50g / m 2 Composite filter material, take by weighing 5.7248g manganese nitrate solution (50wt%), 1.7350g cerium nitrate hexahydrate, be dissolved in water and be made into 100mL solution, the filter material gained in step a is immersed in this solution and stirred for 5h; Weigh 2.6g Dissolve oxalic acid in 100mL water, soak the filter material and let it stand for 12 hou...

Embodiment 2

[0051] a. Take the glass fiber filter material cut into a disc with a diameter of 30mm and completely immerse it in the aqueous solution of 2% alkyl glycoside APG0814, stir for 2 hours, and dry it in a blast drying oven at 115°C for 5 hours to obtain the filter material modified by alkyl glycoside. material.

[0052] b. Add distilled water dropwise on the filter material treated in step a until the filter material is completely soaked, and determine that the saturated water absorption of the filter material with a diameter of 30 mm is 1.8 mL.

[0053] c. In order to obtain Mn: Ce = 4: 1, the load is 80g / m 2 Composite filter material, weigh 8.6513g manganese nitrate solution (50wt%), 2.6218g cerium nitrate hexahydrate, dissolve in water to make 100mL solution, immerse the filter material obtained in step a in the solution and stir for 6h. Weigh 3.9g of oxalic acid and dissolve it in 100mL of water, immerse the filter material and let it stand for 12 hours, dry it in a blast dr...

Embodiment 3

[0058] a. Take the Nomex filter material cut into a disc with a diameter of 30 mm and completely immerse it in an aqueous solution of 3.5% alkyl glycoside APG0814, stir for 2 hours, and dry it in a blast drying oven at 120°C for 4 hours to obtain a filter material modified by alkyl glycoside .

[0059] b. Add distilled water dropwise on the filter material treated in step a until the filter material is completely soaked, and determine that the saturated water absorption of the filter material with a diameter of 30 mm is 2.0 mL.

[0060] c. In order to obtain Mn: Ce = 4: 1, the load is 100g / m 2 Composite filter material, weigh 9.7326g manganese nitrate solution (50wt%), 2.9500g cerium nitrate hexahydrate, dissolve in water to make 100mL solution, immerse the filter material obtained in step a in the solution and stir for 4.5h. Weigh 4.4g of oxalic acid and dissolve it in 100mL of water, immerse the filter material and let it stand for 12 hours, dry it in a blast drying oven at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com