Preparation method for ethylene-series random copolymer

A random copolymerization, ethylene-based technology, applied in the field of preparation of olefin-based random copolymers, can solve the problems of reduced physical and mechanical properties, polymers are prone to gelation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A preparation method of ethylene random copolymer, comprising the following steps:

[0034] Step 1: Treat the reactor with nitrogen in anhydrous and oxygen-free manner under vacuum, then add solvent, ethylene, α-olefin, non-conjugated diene and molecular weight regulator into the reactor, and stir evenly;

[0035] Step 2: Add the main catalyst, co-catalyst and activator to carry out the polymerization reaction. The polymerization reaction temperature is 15-60°C, the reaction pressure is 0.01-2MPa, and the reaction time is 10-180 minutes. The preferred polymerization reaction temperature is 25-45°C , the reaction pressure is 0.1-1 MPa, and the reaction time is 20-60 minutes; and

[0036] Step 3: Add ethanol to terminate the reaction, then add anti-aging agent, remove the solvent from the obtained glue, then separate the glue to obtain the product ethylene random copolymer, and then dry the product to obtain dry glue, wherein there is 0.8 to 1wt in the dry glue % of anti...

Embodiment 1

[0071] The preparation of the ethylene-propylene copolymer is carried out in a 10L reactor with stirring, jacket cooling, inlet pipe, feed pipe, outlet pipe, and outlet pipe. Mix ethylene, propylene, and hydrogen through a mixing device, and then fully mix them uniformly through a circulating compressor. The 10L polymerization kettle is subjected to anhydrous and oxygen-free treatment under vacuum for 1 hour. The inert gas used is high-purity nitrogen, and then Add 5000ml of dry hexane (water content≤10ppm) to it, which contains 18ml of ethylidene norbornene (ENB), turn on the circulation compressor, feed the mixed gas into the polymerization kettle, the mixed gas flow rate is 150L / hour, make the hexane The dissolved mixed gas reaches saturation, and then 20ml of soluble vanadium compound VO(OEt)Cl containing 1mmol is added successively 2 The hexane solution of catalyst, add the mixture of monochlorodiethylaluminum (AM) and trichlorotriethyldialuminum (AQ), wherein the molar r...

Embodiment 2、3、4

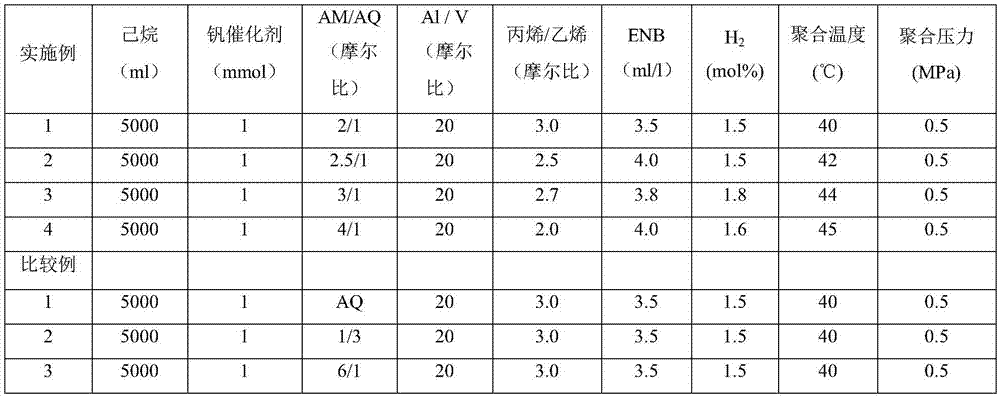

[0073] The polymerization operation process was the same as in Example 1, except that the proportion of mixed aluminum in the cocatalyst was changed, and the addition of reactants and hydrogen were adjusted. See Table 1 for details.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com