Method for enhancing recovery ratio of coal-bed gas by injecting hot carbon dioxide into coal bed

A technology of carbon dioxide and coalbed methane, applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of low coalbed gas storage energy, weak adsorption capacity, limited improvement of coalbed methane recovery rate, etc., to achieve The effect of high recovery rate, sufficient source and wide source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and examples, but of course the following examples should not be construed as limiting the present invention.

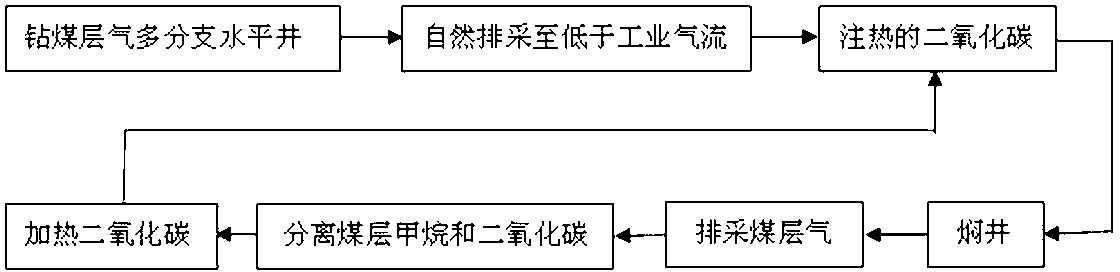

[0031] Such as figure 2 Shown, the present invention provides a kind of method for coal seam heat injection carbon dioxide to improve coal bed methane recovery rate, it is characterized in that, it comprises the steps:

[0032] Step 1: After CBM multi-branch horizontal wells are implemented on the ground, the natural gas production of a single well is lower than the industrial gas flow standard (for example, when the well depth is less than 500m, the gas production of a single well is less than 500m 3 / d; when the well depth is between 500 and 1000m, the single well production is less than 1000m 3 / d).

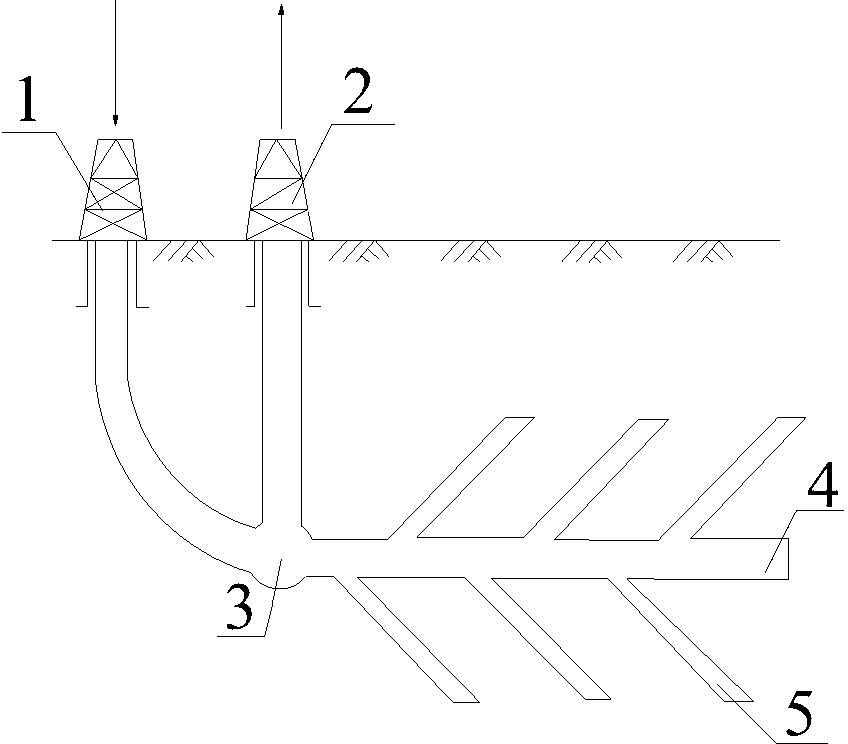

[0033] The multi-branch horizontal well of this embodiment is as figure 1 As shown, a plurality of branch wells 5 are sidetracked on both sides of a main ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com