Alkali lignin-based electrostatic spinning carbon fiber and preparation method and application thereof

A lignin-based, electrospinning technology, which is applied to the chemical characteristics of fibers, circuits, electrical components, etc., can solve the problems of high cost of commercial graphite, and achieve the effect of simple and easy preparation method, low preparation cost and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

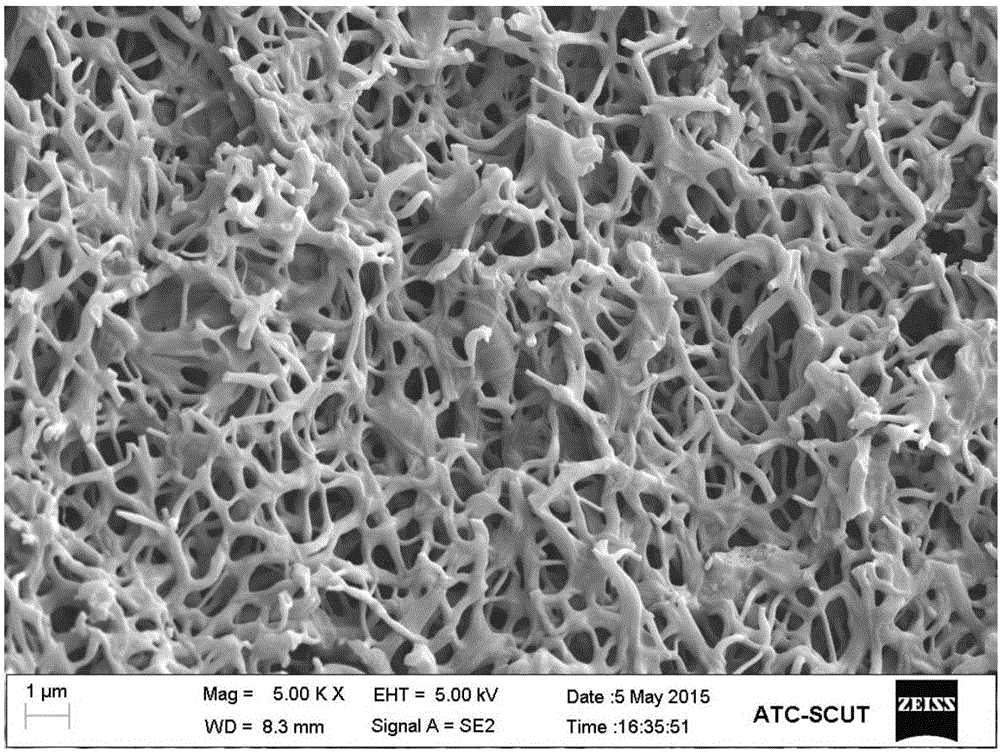

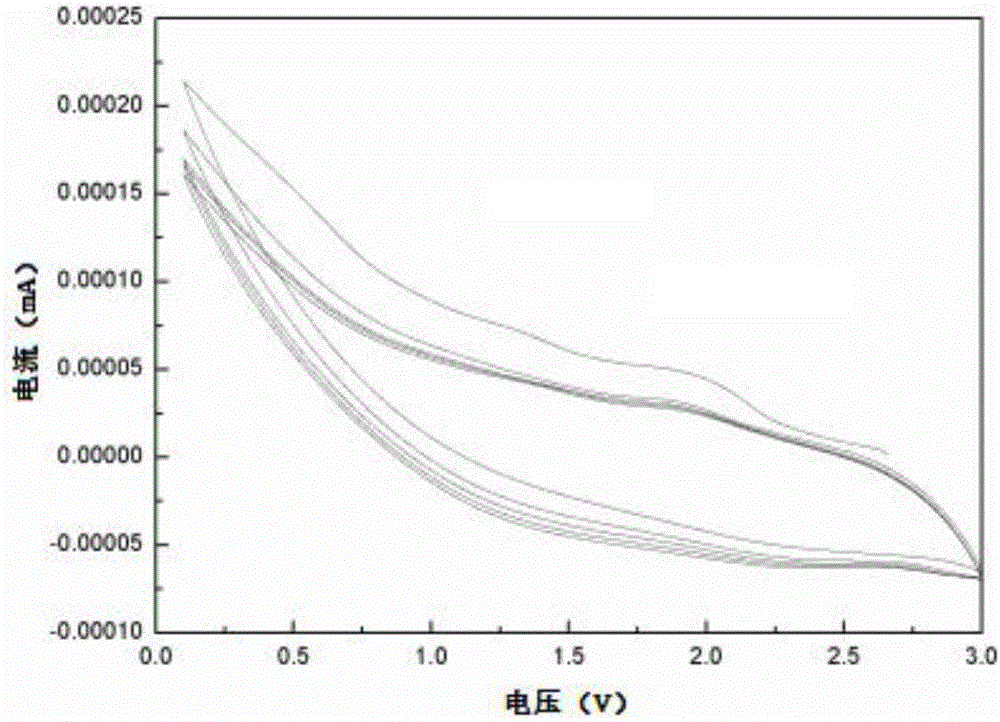

Embodiment 1

[0024] A lignin-based nanofiber film was prepared by electrospinning with a solution of 15% N,N-dimethylformamide in 3 / 7 (w / w) polyacrylonitrile / polyacrylonitrile. Electrospinning The conditions are as follows: the static voltage is 15KV, the receiving distance is 10cm, and the advancing speed of the spinning solution is 1mL / h; the nanofiber membrane is placed in a tube furnace for pre-oxidation and carbonization, and the pre-oxidation temperature is controlled at 200 ℃ , the heating rate is 0.5°C / min, the pre-oxidation time is 2h, and then carbonized, the heating rate is controlled to be 5°C / min, the carbonization temperature is 900°C, and the carbonization time is 2h to obtain the lignin-based carbon nanofiber membrane material, Finally, the alkali lignin-based electrospun carbon fibers are obtained by grinding. It is used as an anode material for lithium batteries, and electrochemical tests are carried out. The research shows that the lignin-based carbon fiber material has ...

Embodiment 2

[0026] A lignin-based nanofiber film was prepared by electrospinning with a 5 / 5 (w / w) N,N-dimethylformamide solution with a mass fraction of 15% sambarine lignin / polyacrylonitrile. Electrospinning The conditions are as follows: the static voltage is 20KV, the receiving distance is 20cm, and the advancing speed of the spinning solution is 5mL / h; the nanofiber membrane is placed in a tube furnace for pre-oxidation and carbonization, and the pre-oxidation temperature is controlled at 200 ℃ , the heating rate is 0.5°C / min, the pre-oxidation time is 2h, and then carbonized, the heating rate is controlled to be 5°C / min, the carbonization temperature is 900°C, and the carbonization time is 2h to obtain the lignin-based carbon nanofiber membrane material, Finally, the alkali lignin-based electrospun carbon fibers are obtained by grinding. It is used as an anode material for lithium batteries, and electrochemical tests are carried out. The research shows that the lignin-based carbon fi...

Embodiment 3

[0028] A lignin-based nanofiber film was prepared by electrospinning with a solution of 7 / 3 (w / w) N,N-dimethylformamide with a mass fraction of 7 / 3 (w / w) polyacrylonitrile. The conditions are as follows: the static voltage is 20KV, the receiving distance is 15cm, and the advancing speed of the spinning solution is 3mL / h; the nanofiber membrane is placed in a tube furnace for pre-oxidation and carbonization, and the pre-oxidation temperature is controlled at 200 ℃ , the heating rate is 2°C / min, the pre-oxidation time is 2h, and then carbonized, the heating rate is controlled to be 5°C / min, the carbonization temperature is 900°C, and the carbonization time is 2h to obtain the lignin-based carbon nanofiber membrane material, Finally, the alkali lignin-based electrospun carbon fibers are obtained by grinding. It is used as an anode material for lithium batteries, and electrochemical tests are carried out. The research shows that the lignin-based carbon fiber material has good elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com