Coating process for pipeline three-layer structural anticorrosive coating

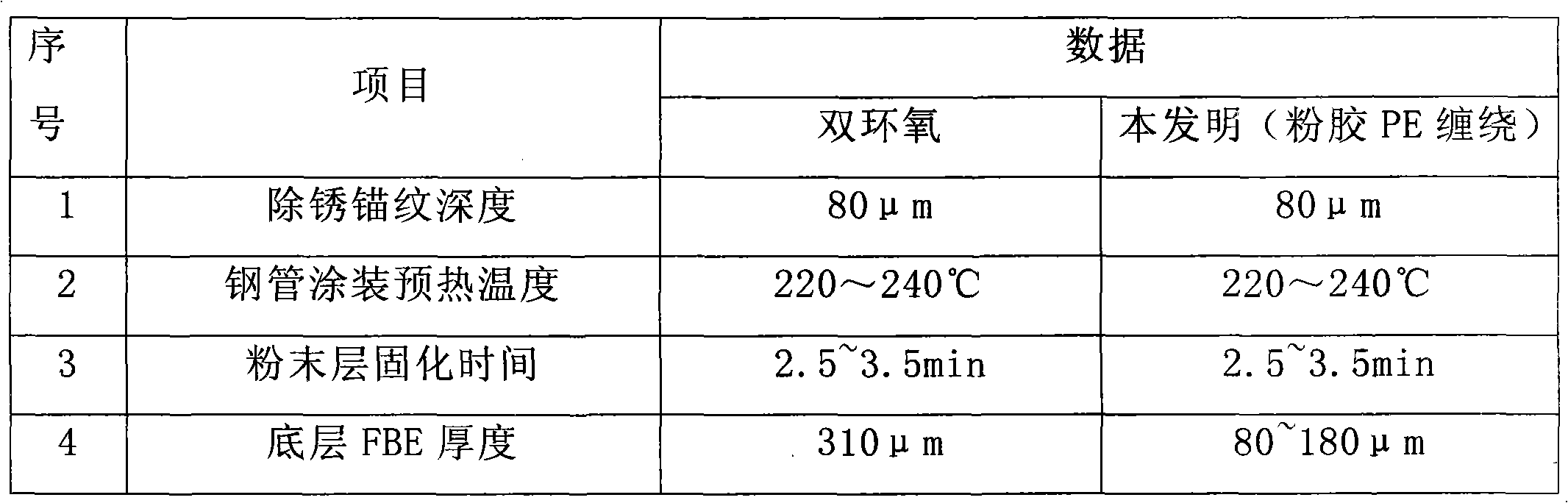

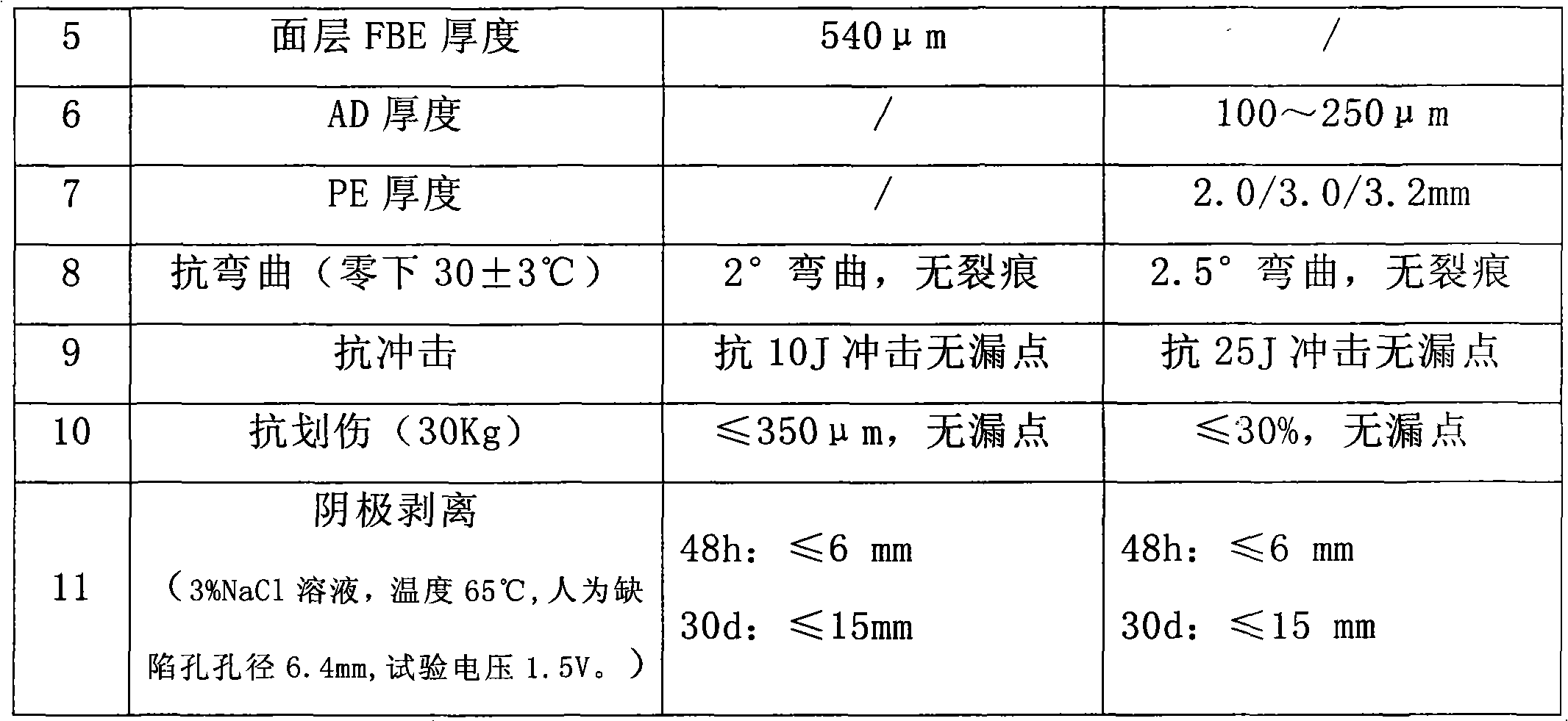

A technology of three-layer structure and coating process, which is applied in the direction of pipeline anticorrosion/rust protection, pipeline protection, and devices for coating liquid on the surface, etc. It can solve the problem of inability to establish surface microcohesion and surface fusion, and the influence of FBE and steel pipe bonding , unable to form surface meshing and other problems, to achieve the effect of low preparation cost, reduced material cost, and improved cathodic disbondment resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A coating process for pipeline three-layer structure anti-corrosion coating, comprising the following steps:

[0047] 1) FBE coating, the curved steel pipe is heated, and epoxy powder is sprayed onto the surface of the curved steel pipe by electrostatic spraying process, so that the epoxy powder coating is melted and solidified into a primer;

[0048] 2) AD coating, during the epoxy powder gelling process, apply the adhesive powder to the surface of the curved steel pipe in step 1), the surface temperature of the curved steel pipe is 170°C, and the coating thickness is 100 μm;

[0049] 3) Polyolefin coating, before the adhesive cools down, wrap the polyolefin PE tape fixing frame heated to 160°C on the curved steel pipe described in step 2) in a lateral winding method, and the tape overlaps by 55% , Heat the surface of the pipe and the PE tape during winding to fuse the PE tape, and the coating thickness is 0.5mm.

Embodiment 2

[0051] A coating process for pipeline three-layer structure anti-corrosion coating, comprising the following steps:

[0052] 1) FBE coating, the steel pipe is heated, and the epoxy powder is sprayed on the surface of the steel pipe by electrostatic spraying process, so that the epoxy powder coating is melted and solidified to form a primer;

[0053] 2) AD coating, before the epoxy powder is gelled, apply the adhesive powder to the surface of the steel pipe in step 1), the surface temperature of the steel pipe is 225°C, and the coating thickness is 350 μm;

[0054] 3) Polyolefin coating, before the adhesive cools down, the polyolefin PP strip heated to 220°C is wound onto the steel pipe described in step 2) through a rotary winding machine, and the strip overlaps by 55%. The surface of the pipe and the PE tape are heated to fuse the PE tape, and the coating thickness is 4.0mm.

Embodiment 3

[0056] A coating process for pipeline three-layer structure anti-corrosion coating, comprising the following steps:

[0057] 1) FBE coating, the substrate to be coated is heated, and epoxy powder is sprayed onto the surface of the substrate to be coated by electrostatic spraying process, so that the epoxy powder coating is melted and solidified into a primer;

[0058] 2) AD coating, before the epoxy powder is gelled, apply the adhesive powder to the surface of the coated substrate in step 1), the surface temperature of the coated substrate is 200°C, and the coating thickness is 200 μm;

[0059] 3) Polyolefin coating, before the adhesive cools down, the AD / PE composite tape of the polyolefin inner layer composite adhesive heated to 200 ° C is wound onto the coated substrate described in step 2) through a rotary winding machine. On the material, the strip overlaps by 55%. When winding, the pipe surface and the PE strip are heated to fuse the PE strip. The coating thickness is 2....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com