Pipe flow type cooling pipe fitting for heating non-combustible cigarette and preparation method thereof

A heating-not-burning and cooling-tube technology, applied in application, tobacco, cigar manufacturing, etc., can solve the problems of small smoke volume, weak bonding, and smoke retention, and achieves a large amount of smoke loaded and rolled Flexible and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] In this embodiment, a pipe fitting for heating non-burning cigarettes is prepared, and the specific method is as follows:

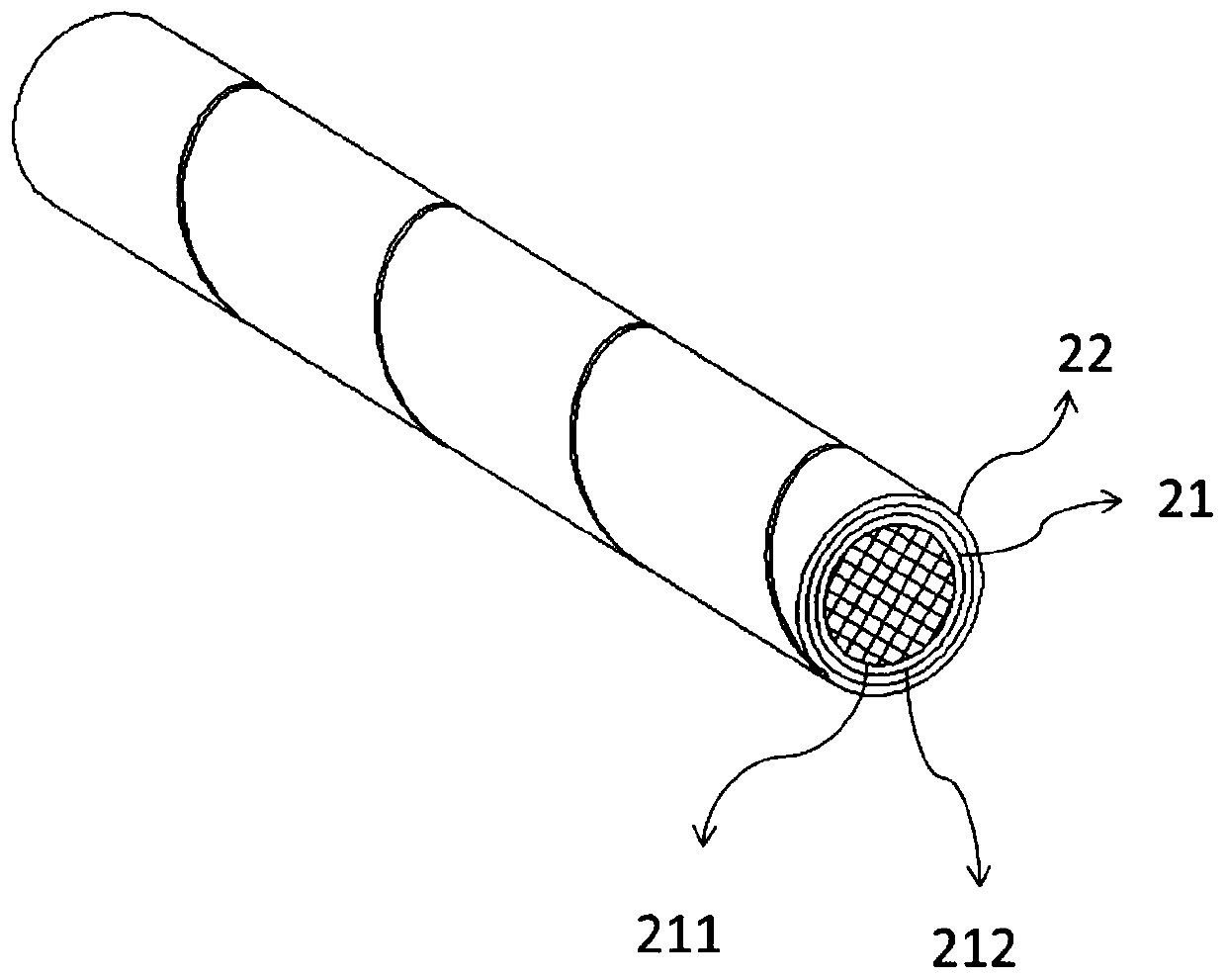

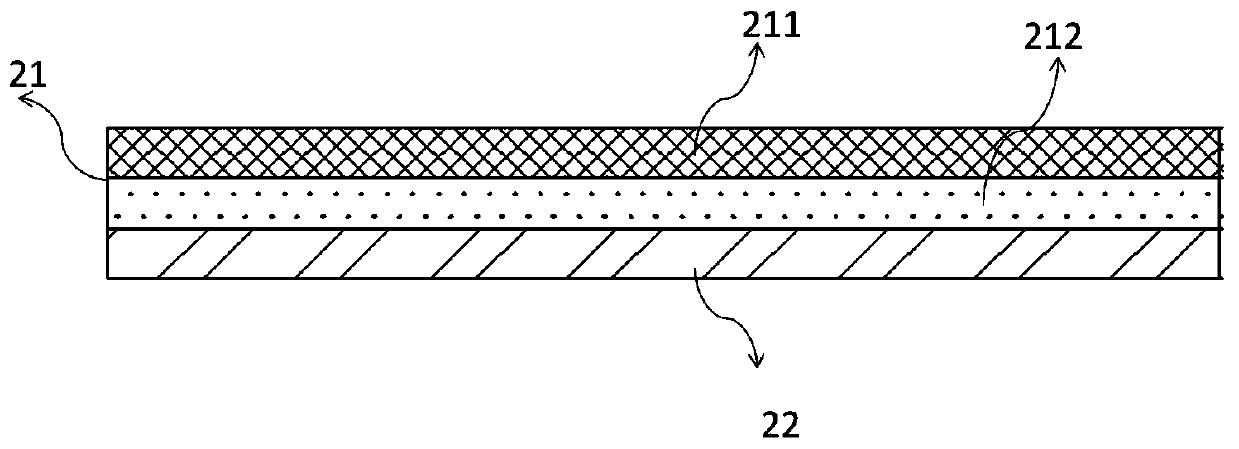

[0041](1) Dry compound a layer of non-woven fabric with the second paper material with a basis weight of 60g / ㎡ through a WRJi9 series solvent-free laminating machine to form a composite layer with a basis weight of 160g / ㎡.

[0042] (2) Cut the compounded composite layer roll into small rolls with a width of 12 mm.

[0043] (3) Use the composite layer and two rolls of the first paper material with a weight of 110g / ㎡ to form pipe fittings through a spiral pipe machine, and apply fragrance on the non-woven fabric surface of the composite layer by roller transfer during the forming process gel.

[0044] Wherein, the wall thickness of the formed pipe fitting is 0.6mm. The short fibers of the polylactic acid material are oriented and arranged to form a fiber net structure, and then the polylactic acid non-woven fabric layer is formed by reinforcing wit...

Embodiment 2

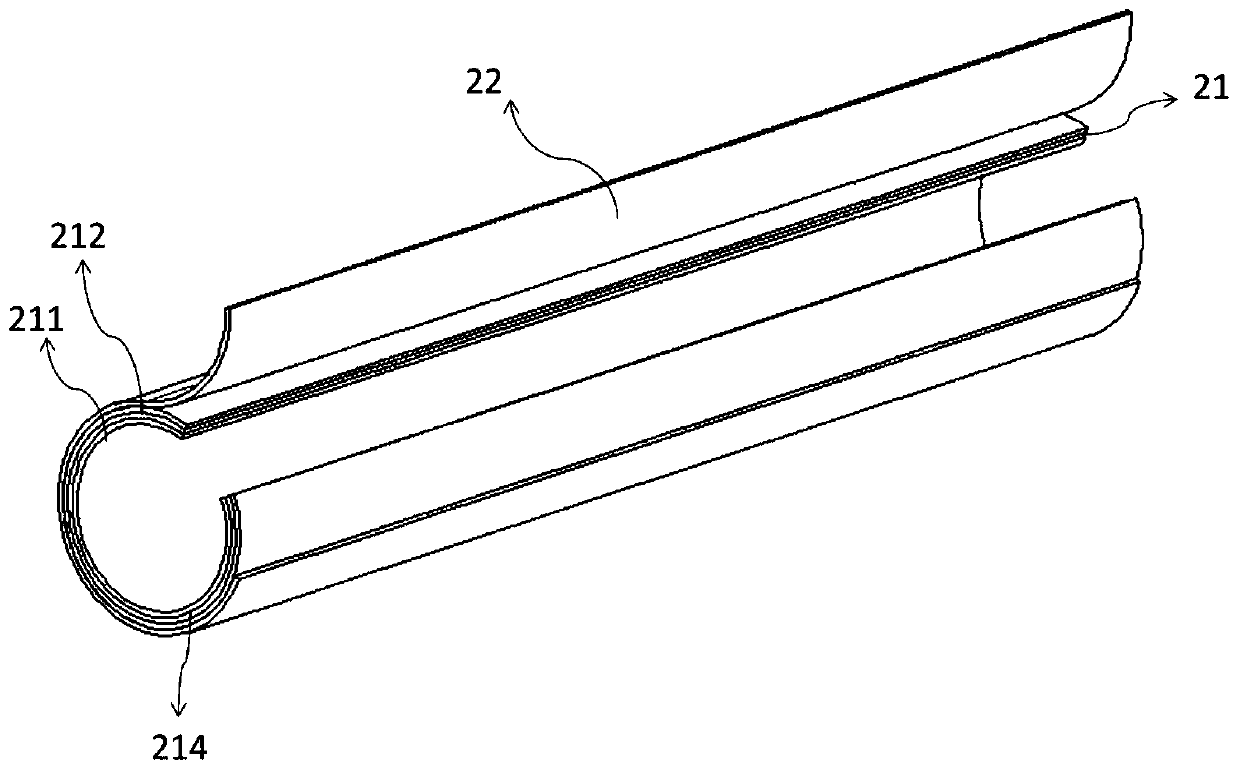

[0047] In this embodiment, a pipe fitting for heating non-burning cigarettes is prepared, and the specific method is as follows:

[0048] (1) A layer of non-woven fabric and a layer of PLA film are dry compounded by WRJi9 series solvent-free laminating machine. After compounding, the PLA film surface is dry compounded with the second paper material with a weight of 60g / ㎡. It is a composite layer, one side of the composite layer is non-woven fabric, one side is the second paper material, and the middle is PLA film.

[0049] (2) Spray the fragrance-carrying gel on the non-woven fabric surface of the composite layer.

[0050] (3) The composite layer coated with fragrance-carrying gel and the first paper strip with a weight of 110g / ㎡ are made into pipe fittings by overlapping composite molding pipe fittings.

[0051] The wall thickness of the molded fragrance-carrying non-woven pipe fitting is 0.6 mm. The short fibers of the polylactic acid material are oriented and arranged to ...

Embodiment 3

[0054] This embodiment is a heat-not-burn cigarette, which sequentially includes: a cigarette core section 1, a cooling section 2 and a filter section 3;

[0055] The cooling section 2 is the pipe fitting prepared in Example 2.

[0056] The cooling section 2 and the filter section 3 are wrapped with molding paper 4 to form a binary composite tip, and the cigarette core section 1 is wrapped with cigarette paper 5 to form a tobacco segment. The binary composite tip and the tobacco The segments are tipped by tipping paper 6.

[0057] The length of the cooling section 2 is 24mm.

[0058] Wherein, the filter section 3 is a solid filter made of cellulose acetate tow material, and the length of the filter section 3 is 8 mm.

[0059] Wherein, the cigarette core section 1 is a rod-shaped cigarette core formed by gathering reconstituted tobacco leaves containing aroma substances, the length of the cigarette core section 1 is 13mm, and the diameter of the cigarette core section 1 is 7....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com