Forming method of silica gel diaphragm, silica gel diaphragm and sounding device

A technology of silicone diaphragm and molding method, which is applied to sensors, electrical components, loudspeakers, etc., can solve the problems of reducing product reliability, deformation of polymer diaphragms, and difficulty in bonding other components, and achieves the effect of suppressing rolling vibration. , Improve the overall strength, increase the effect of damping characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

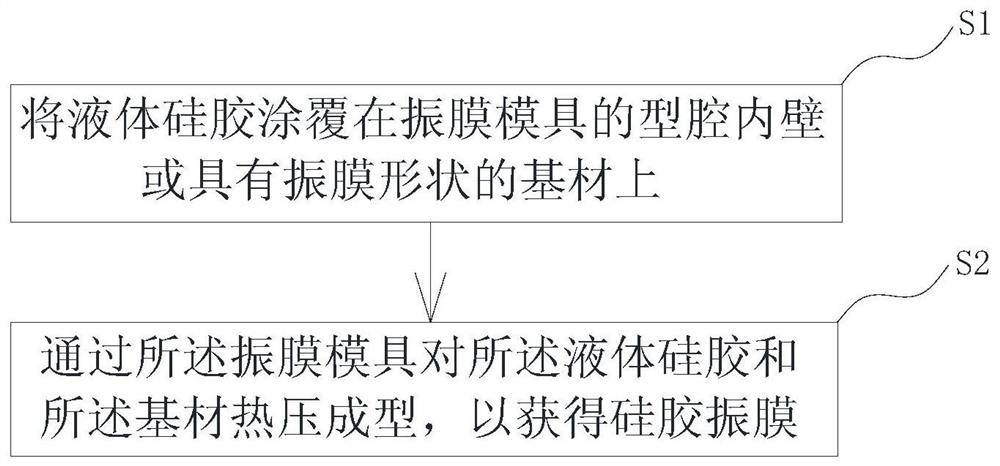

[0059] like Figure 1 to Figure 12 As shown, the invention provides a molding method of a silica gel diaphragm, which comprises the following steps:

[0060] Step S1: coating the liquid silicone 1' on the inner wall of the cavity 31 of the diaphragm mold 3 or the substrate 2 having the shape of the diaphragm;

[0061] Step S2: The liquid silicone 1' and the substrate 2 are thermally press-molded through the diaphragm mold 3 to obtain a silica gel diaphragm 10.

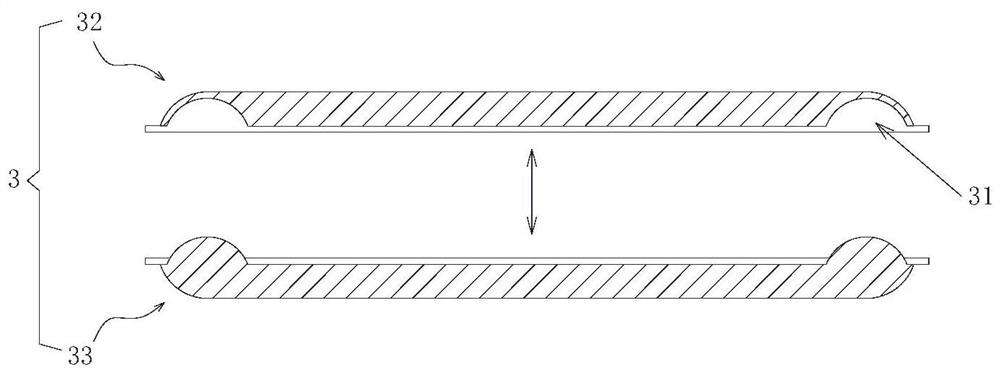

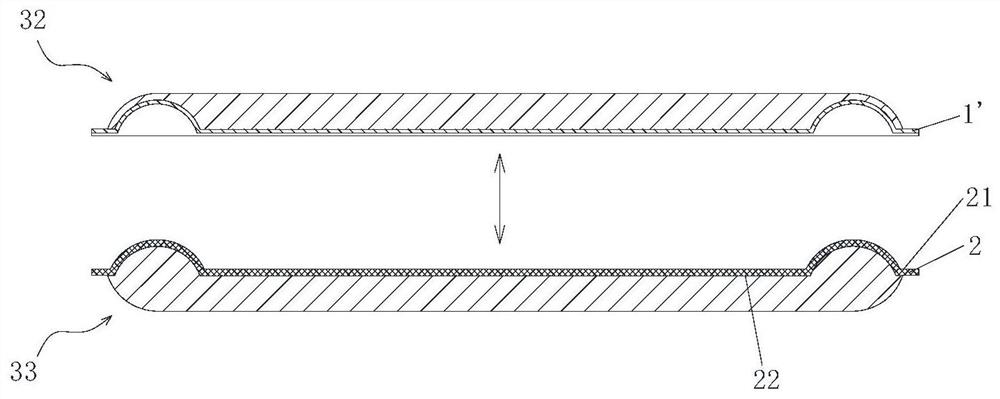

[0062] Specifically, such as figure 2 As shown, the diaphragm mold 3 includes an upper mold 32 and a lower mold 33 that can be buckled together. After the upper mold 32 and the lower mold 33 are buckled, a cavity 31 that can accommodate the substrate 2 and the liquid silicone 1' is formed. In this embodiment, the structure of the cavity 31 is consistent with the structure of the silicone diaphragm 10 to be formed; The structure of the diaphragm 10 is consistent. Please refer to Figure 7 to Figure 12 As shown, th...

Embodiment approach 2

[0076] like Figure 7 to Figure 12 As shown, the present invention also provides a silica gel diaphragm 10, which is made by the molding method of the silica gel diaphragm described in the first embodiment, wherein the molding method of the silica gel diaphragm has been specifically described in the first embodiment , the selected materials, process steps and beneficial effects will not be repeated here. The silicone diaphragm 10 includes a substrate 2 and a silica gel layer 1 positioned on one side of the substrate 2. The silica gel diaphragm 10 has a ring portion 102, and the inner periphery of the ring portion 102 is connected with a center paste portion 101. The outer peripheral edge of the ring portion 102 is connected with a hanging edge portion 103 . Wherein, the ring part 102 is a ring-shaped structure or other curved structure that is raised relative to the surface of the middle post part 101. Concave-convex shape structure is provided on it, and the hanging edge po...

Embodiment approach 3

[0087] like Figure 16 and Figure 17 As shown, the present invention also provides a sounding device 20, which includes a magnet structure 5, a frame 4 and a silicone diaphragm 10, wherein the silica gel diaphragm 10 is the silica gel diaphragm described in Embodiment 2, and its specific structure, The molding process, working principle and effective effect will not be repeated here. The magnet structure 5 has a magnetic bowl 51, a magnet block 52 is bonded inside the magnetic bowl 51, and a magnet top plate 53 is bonded to the magnet block 52; one side of the basin frame 4 is sealed and connected with the magnetic bowl 51; the silicone diaphragm 10 is sealed Connected to the other side of the basin frame 4 , the silicone diaphragm 10 is connected with a voice coil 7 , and the voice coil 7 is located in the magnetic bowl 51 .

[0088] Specifically, the magnet structure 5 mainly establishes a fixed magnetic field for the sound generating device 20 . The magnet structure 5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com