Permanent-magnet motor and method of fixing rotor magnetic steel

A permanent magnet motor and rotor technology, which is applied to the rotating parts of the magnetic circuit, the shape/style/structure of the magnetic circuit, etc., can solve the problems related to the permanent magnet motor and its rotor magnets, avoid the risk of easy falling off, and simplify the process , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The detailed technical contents and embodiments of the present invention will be further described below in conjunction with the accompanying drawings. Please note that the embodiments described here are only illustrative, and not intended to limit aspects of the present invention. In the drawings, the same reference numerals designate the same or similar components.

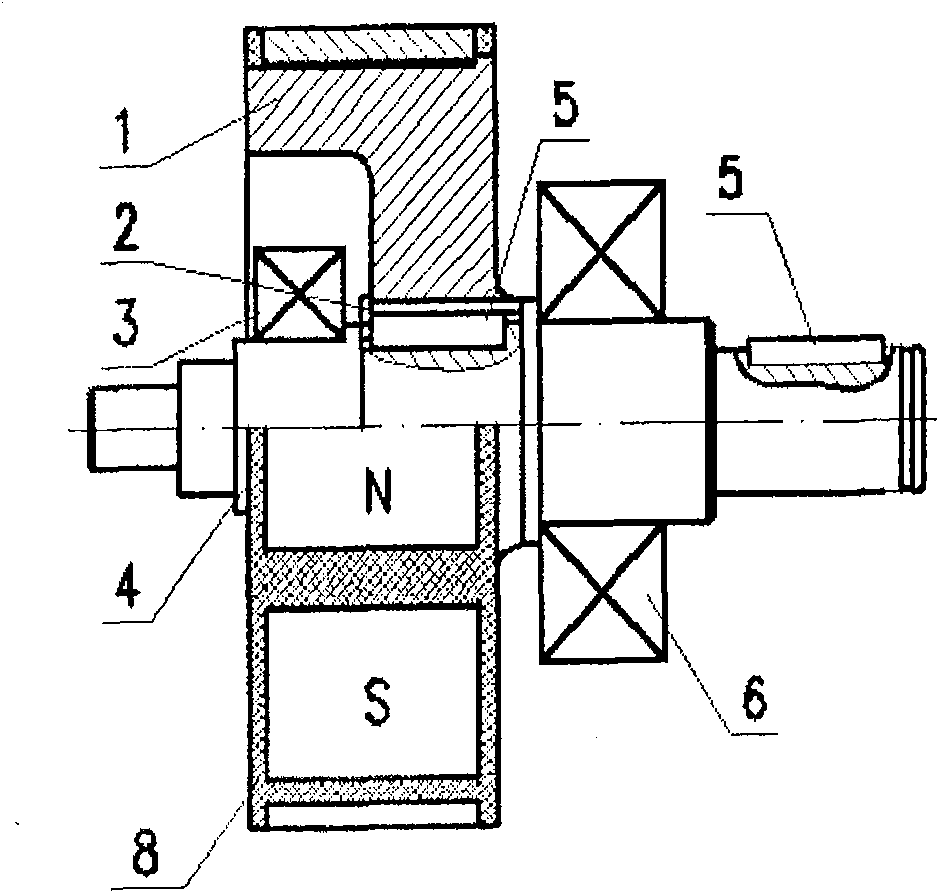

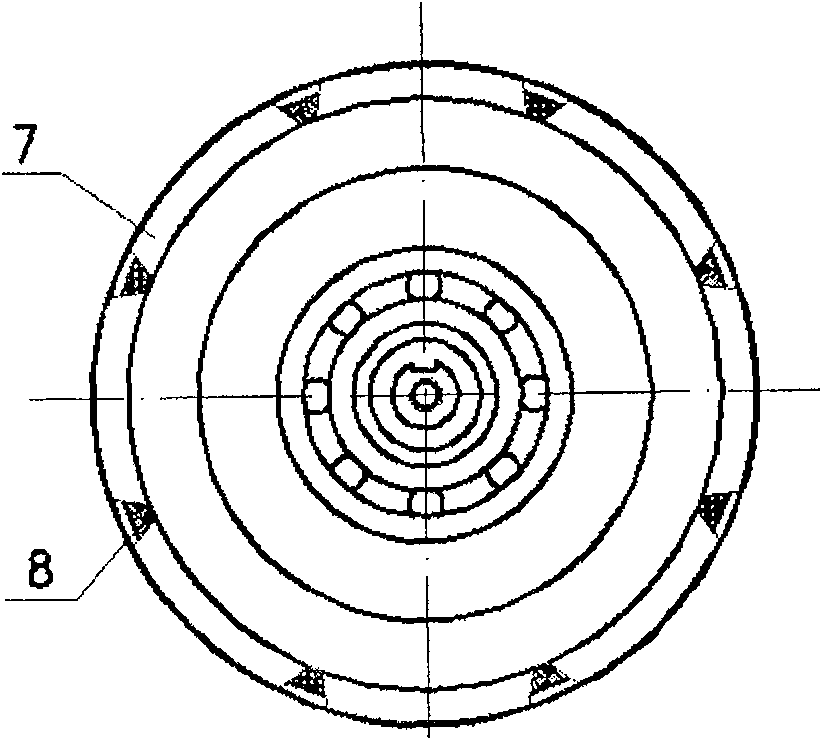

[0023] figure 1 and figure 2 The permanent magnet motor shown includes a permanent magnet motor composed of a stator and a rotor, wherein: the rotor part is composed of a rotor yoke 1, a retaining spring 2, a bearing 3, shafts 4 and 6, a key 5, a permanent magnet 7, and a balance mud 8 constitute,

[0024] The shape of the permanent magnet 7 is a concentric arc shape,

[0025] The balance mud 8 is a two-component epoxy curing agent, and the rotor as a whole has a squirrel-cage structure through bonding.

[0026] The permanent magnet motor is characterized in that: the permanent magnet 7 is in the sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com