A method of loading two-dimensional visible photocatalytic materials on organic polymer fibers

A technology of organic polymers and polymer fibers, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc., can solve the problem of difficult recovery of photocatalysts, and achieve Improved degradation efficiency, low price, and short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

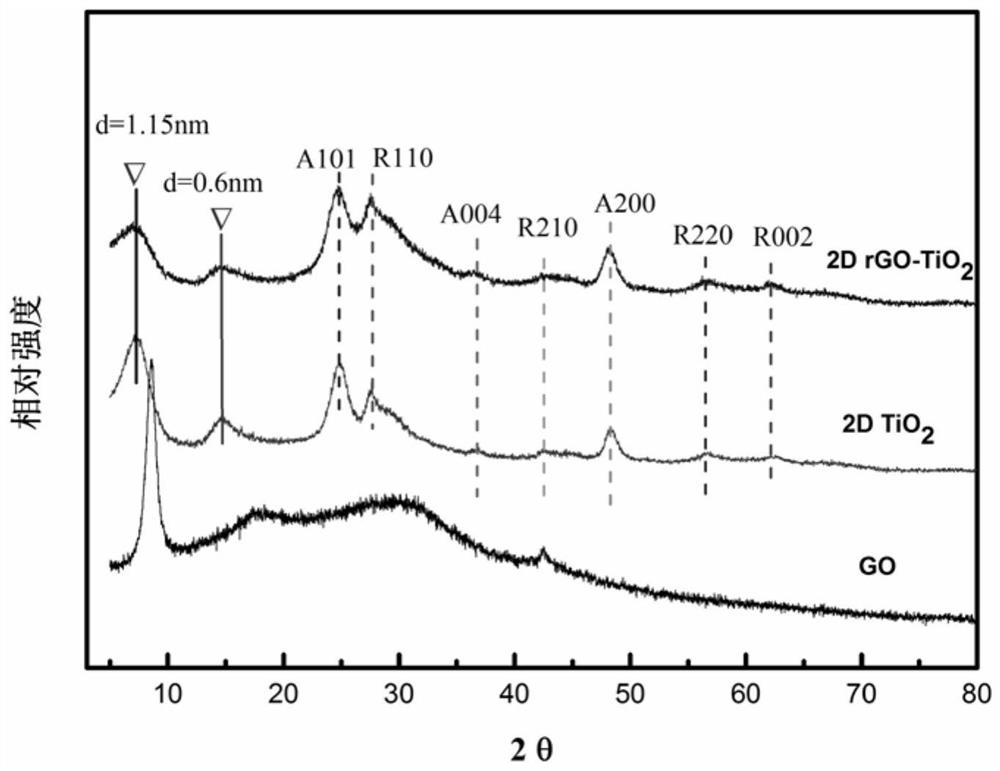

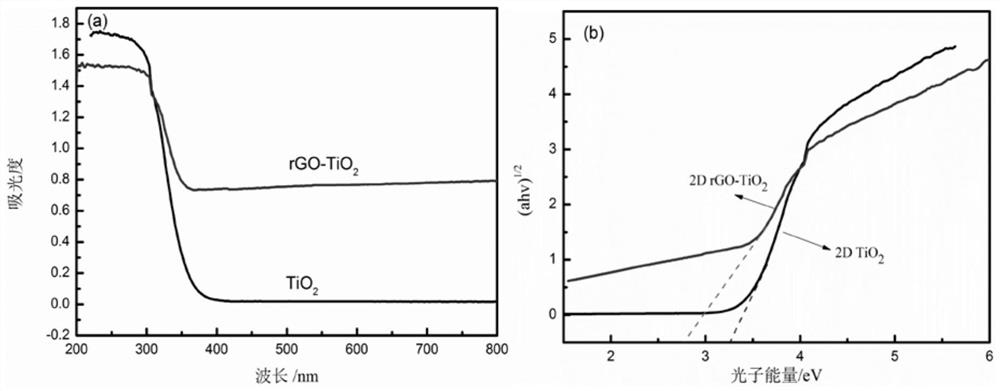

[0034] The two-dimensional ultra-high specific surface area rGO-TiO of this embodiment 2 The preparation method of the polypropylene fiber supported by photocatalyst, the preparation steps are as follows:

[0035] The molar ratio of titanium isopropoxide: ethylene glycol: ethanol in the synthetic solution is 1:97:17, the content of hydrochloric acid is 0.3 mol / L, the structure directing agent L64 is 0.003 mol / L, and GO is 0.06 mg / ml.

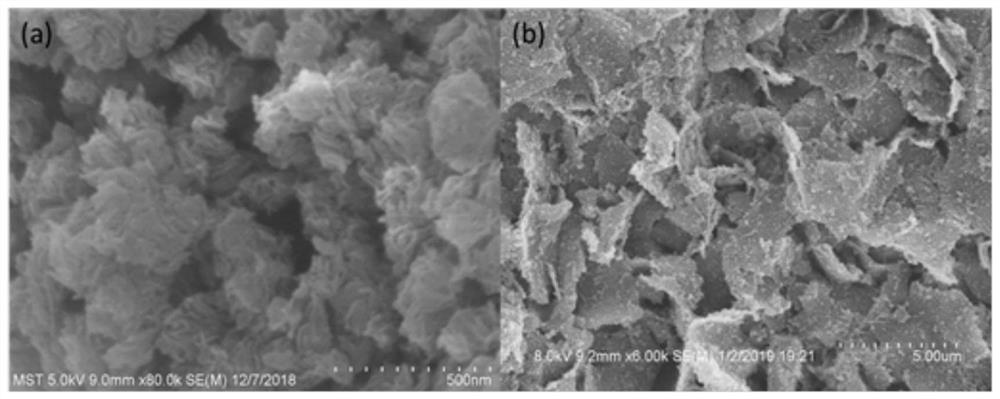

[0036] (1) Preparation of seed crystal treated polypropylene fiber: take a certain amount of TiO 2 powder, configured as a 0.1% ethanol solution, and ultrasonically stirred to make TiO 2 Uniformly disperse to form a seed liquid, and then soak the polypropylene fiber with a size of 5×5 cm in the seed liquid for 6 hours, then take it out and dry it at 50°C for later use. Figure 5 It is the SEM image of the polypropylene fiber surface treated with the seed liquid.

[0037] (2) Liquid A: Use a precision electronic balance to take 0.74g (37wt%) h...

Embodiment 2

[0055] The two-dimensional ultra-high specific surface area rGO-TiO of this embodiment 2 The preparation method of the polypropylene fiber supported by photocatalyst, the preparation steps are as follows:

[0056] The molar ratio of titanium isopropoxide: ethylene glycol: ethanol in the synthetic solution is 1:91:12, the content of hydrochloric acid is 0.1 mol / L, the structure directing agent L64 is 0.001 mol / L, and the GO is 0.12 mg / ml.

[0057] (1) Preparation of seed crystal treated polypropylene fiber: take a certain amount of TiO 2 Powder, configured as a 0.03% ethanol solution, ultrasonically stirred to make TiO 2 Uniformly disperse to form a seed liquid, and then soak the polypropylene fiber with a size of 5×5 cm in the seed liquid for 12 hours, then take it out and dry it at 80°C for later use.

[0058] (2) Liquid A: Use a precision electronic balance to take 0.25g (37wt%) hydrochloric acid and 1.05g titanium isopropoxide respectively in two small beakers, then slowl...

Embodiment 3

[0062] The two-dimensional ultra-high specific surface area rGO-TiO of this embodiment 2 The preparation method of the polypropylene fiber supported by photocatalyst, the preparation steps are as follows:

[0063] The molar ratio of titanium isopropoxide: ethylene glycol: ethanol in the synthetic solution is 1:95:20, the sulfuric acid content is 0.5 mol / L, the structure directing agent P123 is 0.005 mol / L, and GO is 0.18 mg / ml.

[0064] (1) Preparation of seed crystal treated polypropylene fiber: take a certain amount of TiO 2 Powder, configured as a 0.3% ethanol solution, ultrasonically stirred to make TiO 2 Uniformly disperse to form a seed liquid, and then soak the polypropylene fiber with a size of 5×5 cm in the seed liquid for 18 hours, and then take it out and dry it at 100°C for later use.

[0065] (2) Liquid A: use a precision electronic balance to take 1.23g (96wt%) sulfuric acid and 1.05g titanium isopropoxide respectively in two small beakers, then slowly drop the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com