Wavelength Selective Radiator Coating Applied to Thermal Photovoltaic Power Generation Devices and Preparation Method

A wavelength-selective, thermal photovoltaic power generation technology, applied in coatings and other directions, can solve the problems of difficulty in controlling the spectrum of coating radiators, poor bonding between thick coatings and substrates, and no coating radiators have been developed. Practical application value, no surface chipping, effect of improving the mechanical properties of the coating and the surface strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

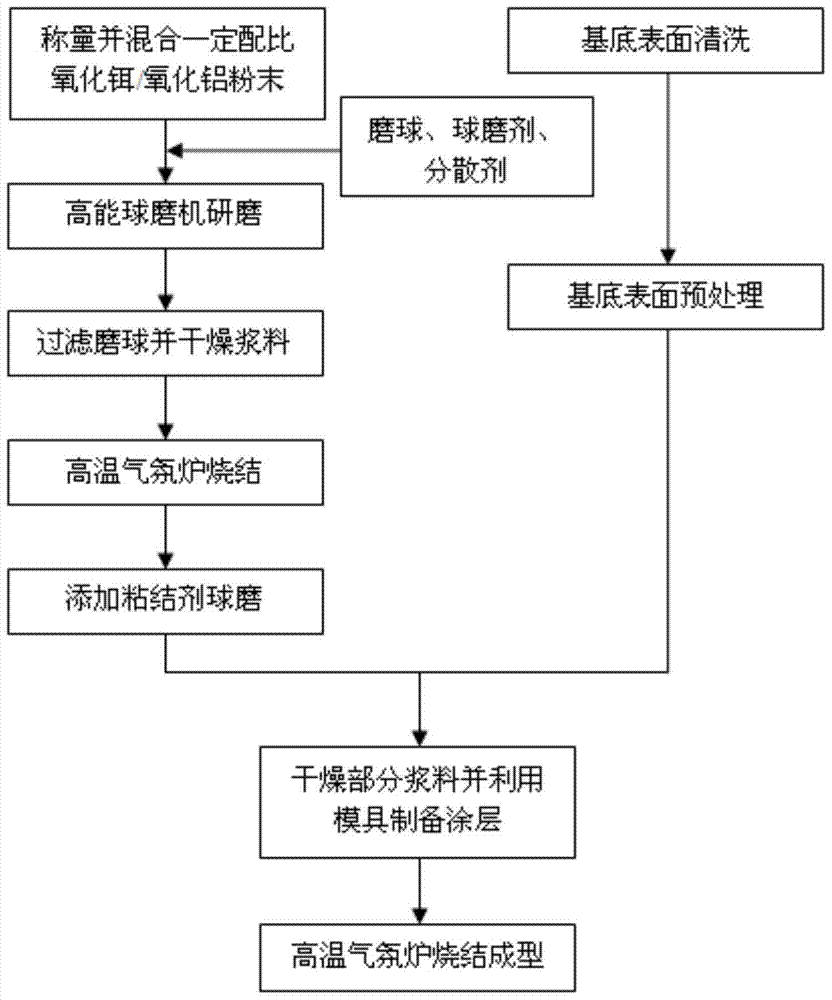

[0029] The wavelength selective radiator coating applied to the thermal photovoltaic power generation device of the present invention is prepared by the following steps, the steps are as follows:

[0030] Step 1, weigh 38 grams of Er respectively according to the stoichiometric ratio 2 o 3 , 42 g Al 2 o 3 Powder (nanoscale), 80 grams of absolute ethanol, 4 grams of dispersant PEG2000, prepared to contain 47.5% Er 2 o 3 The mixed slurry was ground by a high-energy ball mill for 10 hours to make it completely mixed. Add the same absolute ethanol as the powder mass and 5% powder mass dispersant polyethylene glycol (PEG2000).

[0031] Step 2, take out the uniformly mixed slurry, filter the balls, place the mixed slurry in a constant temperature and humidity drying oven, dry at 65°C and completely remove absolute ethanol, then take out the mixed powder.

[0032] Step 3, take out the mixed powder after drying in step 2, and place it in a corundum crucible, place it in a high-t...

Embodiment 2

[0040] The wavelength selective radiator coating applied to the thermal photovoltaic power generation device of the present invention is prepared by the following steps, the steps are as follows:

[0041] Step 1, weigh 8 grams of Er respectively according to the stoichiometric ratio 2 o 3 , 72 g Al 2 o 3 Powder (nanoscale), 80 grams of absolute ethanol, 4 grams of dispersant PEG2000, prepared with 10% Er 2 o 3 The mixed slurry was ground by a high-energy ball mill for 10 hours to make it completely mixed. Add the same absolute ethanol as the powder mass and 5% powder mass dispersant polyethylene glycol (PEG2000).

[0042] Step 2, take out the uniformly mixed slurry, filter the balls, place the mixed slurry in a constant temperature and humidity drying oven, dry at 50°C and completely remove the absolute ethanol, then take out the mixed powder.

[0043] Step 3, take out the mixed powder after drying in step 2, and place it in a corundum crucible, place it in a high-temper...

Embodiment 3

[0048] Step 1, weigh 65 grams of Er respectively according to the stoichiometric ratio 2 o 3 , 35 g Al 2 o 3 Powder (nanoscale), 100 grams of absolute ethanol, 5 grams of dispersant PEG2000, prepared containing 65% Er 2 o 3 The mixed slurry was ground by a high-energy ball mill for 10 hours to make it completely mixed. Add the same absolute ethanol as the powder mass and 5% powder mass dispersant polyethylene glycol (PEG2000).

[0049] Step 2: Take out the homogeneously mixed slurry, filter the balls, place the mixed slurry in a constant temperature and humidity drying oven, dry at 80°C and completely remove absolute ethanol, and then take out the mixed powder.

[0050] Step 3, take out the mixed powder after drying in step 2, and place it in a corundum crucible, place it in a high-temperature furnace, set a heating program, and sinter the composite powder at a maximum temperature of 1600°C and keep it warm for 3 hours.

[0051] Step 4, after taking out the mixed powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com