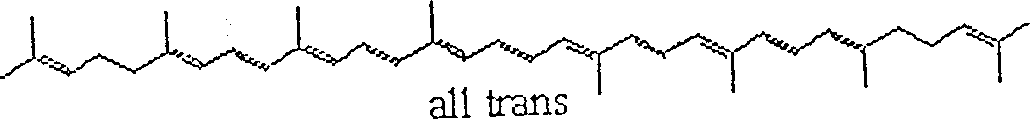

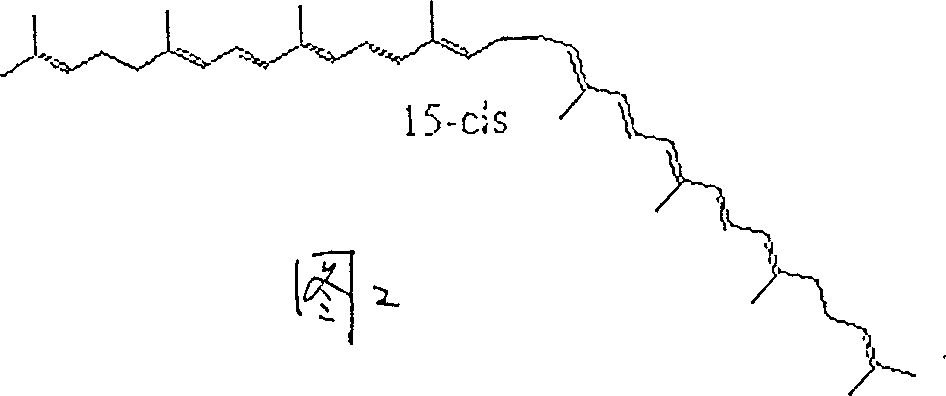

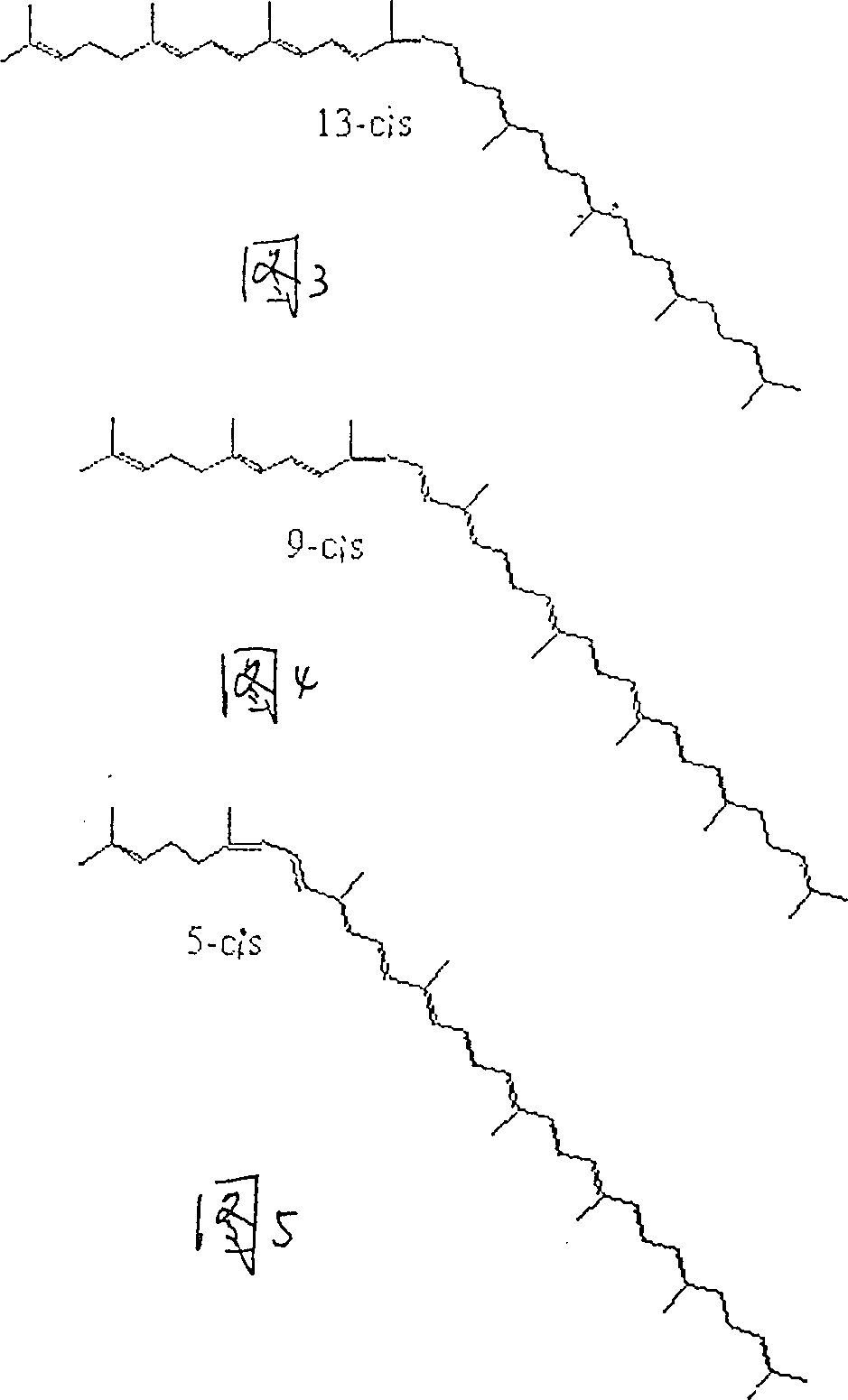

Preparation method of lycopene richly containing cis-isomer

A technology of cis-isomer and lycopene, which is applied in the field of preparation of lycopene rich in cis-isomer, can solve the problems that the preparation method has not yet been reported, and achieve low cost, many types of products, and raw materials The effect of readily available sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Take 1kg of tomato paste and 1kg of soybean oil into a 5L three-necked flask, heat in a water bath to 50°C for 3 hours, filter to obtain the soybean oil clear liquid and tomato paste residue, put the soybean oil clear liquid into a rotary evaporator, and heat to 35°C for 6.5 hours, vacuum pressure -0.08MPa to condense and reflux to obtain the product of the present invention, and its cis-to-trans structure ratio is 11.5%:67.0%.

Embodiment 2

[0024] Take 1kg of tomato paste, 1.5kg of peanut oil and 1.5kg of corn oil and put them into a 5L three-necked flask, heat it in a water bath to 10°C for 5 hours, filter to obtain the clear liquid of peanut oil and corn oil and tomato sauce residue, and then add it to the tomato sauce residue 0.5kg of soybean oil was processed according to the above conditions for a second cycle, and the obtained clear liquid was mixed, heated to 60°C for 4 hours, and condensed and refluxed at a vacuum pressure of -0.1MPa to obtain the product of the present invention, its cis and trans The structure ratio is 40.3%:54.4%.

Embodiment 3

[0026] Take 1kg of tomato paste, 1kg of rice bran oil, 2kg of pumpkin seed oil and 2kg of watermelon seed oil, add them to a 10L three-necked flask, heat them in a water bath to 98°C for 0.5 hours, and filter to obtain rice bran oil, pumpkin seed oil and watermelon seed oil clear liquid and Tomato sauce residue, then add 1.5kg of the above raw materials to the tomato paste residue and perform four cycles according to the above conditions, the obtained clear liquid is mixed, heated to 98°C for 2 hours, and vacuum pressure -0.05MPa to carry out N 2 Condensed and refluxed to obtain the product of the present invention, the ratio of cis and trans structures is 48.1%:46.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com