Transition metal sulfide coated with carbon, preparation method and application

A transition metal and surface coating technology, applied in the field of transition metal sulfides, can solve problems such as battery short circuit and current collector corrosion, and achieve the effects of high battery capacity, good conductivity and good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

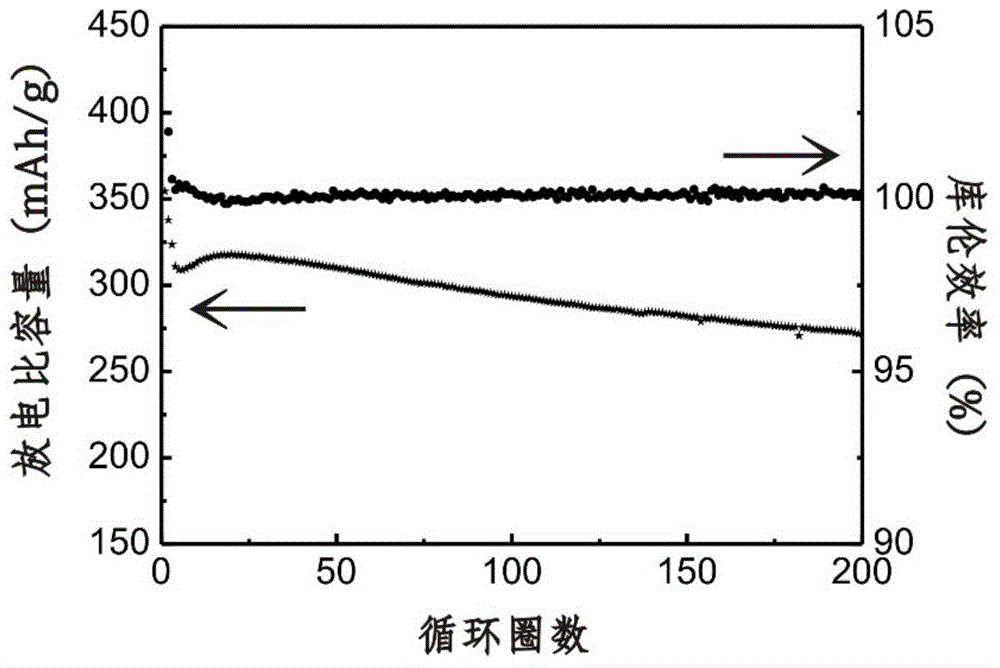

Embodiment 1

[0055] Dissolve 1g of CuS in 50mL of water, add 2g of glucose, transfer to a 100mL hydrothermal kettle, react for 24h, and calcinate at 500°C for 10h. Obtain the surface carbon-coated sulfur-copper compound, mix the prepared surface carbon-coated sulfur-copper compound 0.5g with 0.1071g acetylene black and 0.1071g polyvinylidene fluoride (PVDF), add an appropriate amount of N-methylpyrrolidone ( NMP) was dissolved, and the slurry was coated on the copper current collector to make an electrode. The test electrode was dried in a vacuum oven at 60°C for 12 hours, and the battery was assembled in a high-purity argon atmosphere glove box. The electrolyte is 1 mol of lithium bis(trifluoromethyl)sulfonylimide (LiTFSI) salt, and the solvent is 1,2-dimethoxyethane (DME) and 1,3-diox Pentacycline (DOL) mixed solution, lithium salt concentration is 1mol / L. A 2016 button battery was assembled with glass fiber filter paper as the liquid-absorbing membrane, Celgard 2400 membrane as the di...

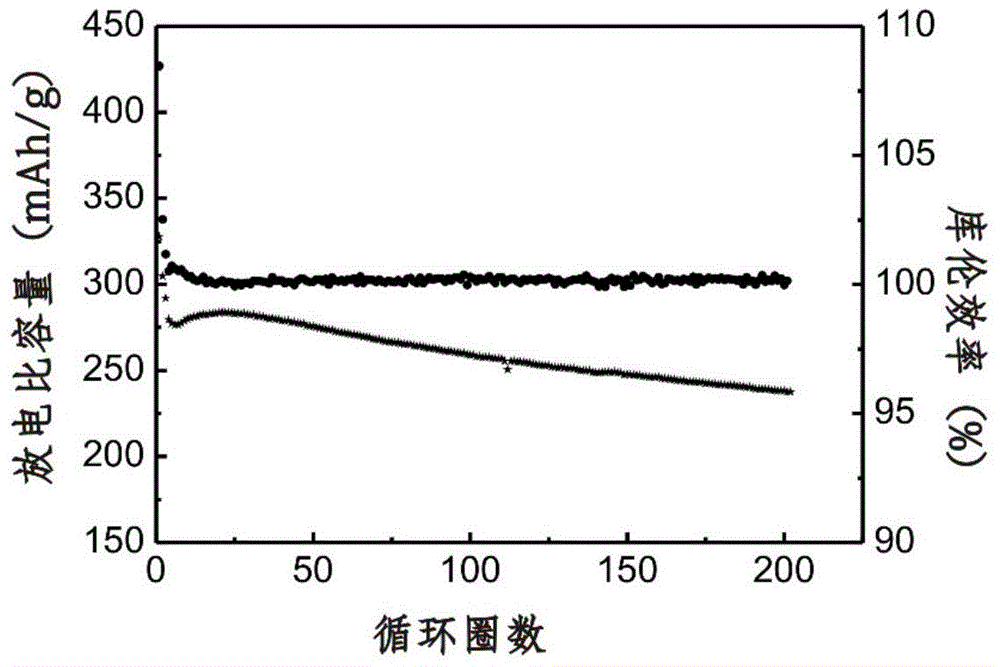

Embodiment 2

[0058] Dissolve 1g of CuS in 50mL of water, add 1.5g of glucose, transfer to a 100mL hydrothermal kettle, react for 24h, and calcine at 500°C for 10h. Obtain the surface carbon-coated sulfur-copper compound, mix the prepared surface carbon-coated sulfur-copper compound 0.5g with 0.1071g acetylene black and 0.1071g polyvinylidene fluoride (PVDF), add an appropriate amount of N-methylpyrrolidone ( NMP) was dissolved, and the slurry was coated on the copper current collector to make an electrode. The test electrode was dried in a vacuum oven at 60°C for 12 hours, and the battery was assembled in a high-purity argon atmosphere glove box. The electrolyte is 1 mol of lithium bis(trifluoromethyl)sulfonylimide (LiTFSI) salt, and the solvent is 1,2-dimethoxyethane (DME) and 1,3-diox Pentacycline (DOL) mixed solution, lithium salt concentration is 1mol / L. A 2016 button battery was assembled with glass fiber filter paper as the liquid-absorbing membrane, Celgard 2400 membrane as the di...

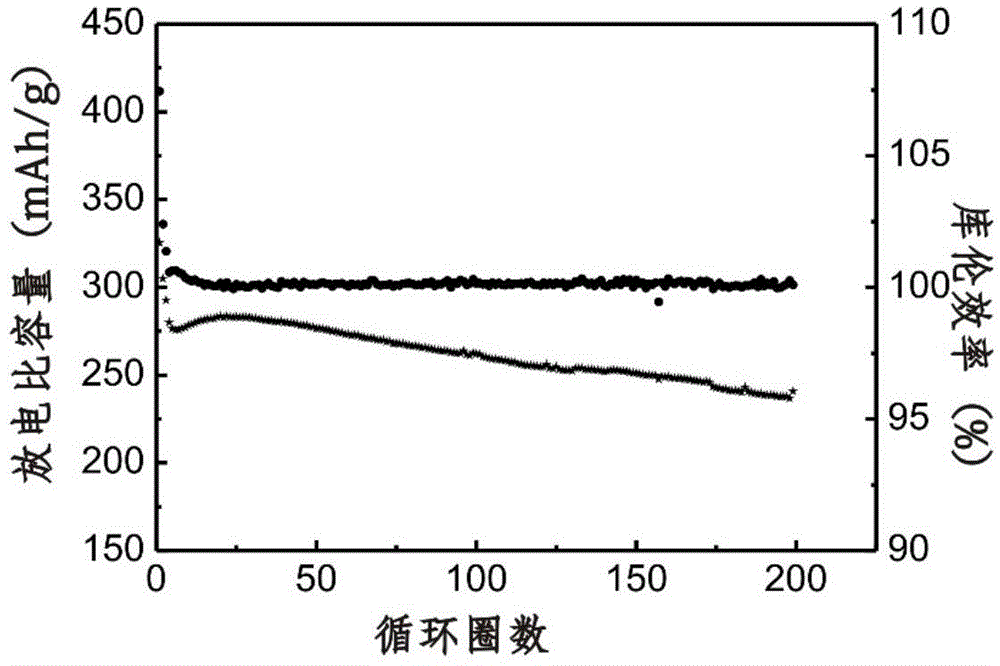

Embodiment 3

[0061] Dissolve 1g of CuS in 50mL of water, add 1g of glucose, transfer to a 100mL hydrothermal kettle, react for 24h, and calcine at 500°C for 10h. Obtain the surface carbon-coated sulfur-copper compound, mix the prepared surface carbon-coated sulfur-copper compound 0.5g with 0.1071g acetylene black and 0.1071g polyvinylidene fluoride (PVDF), add an appropriate amount of N-methylpyrrolidone ( NMP) was dissolved, and the slurry was coated on the copper current collector to make an electrode. The test electrode was dried in a vacuum oven at 60°C for 12 hours, and the battery was assembled in a high-purity argon atmosphere glove box. The electrolyte is 1 mol of lithium bis(trifluoromethyl)sulfonylimide (LiTFSI) salt, and the solvent is 1,2-dimethoxyethane (DME) and 1,3-diox Pentacycline (DOL) mixed solution, lithium salt concentration is 1mol / L. A 2016 button battery was assembled with glass fiber filter paper as the liquid-absorbing membrane, Celgard 2400 membrane as the diap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com