Shaddock peel activated carbon preparation method

A pomelo peel and activated carbon technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems such as pollution of the environment and waste of resources, and achieve the effects of good adsorption performance, many pores and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

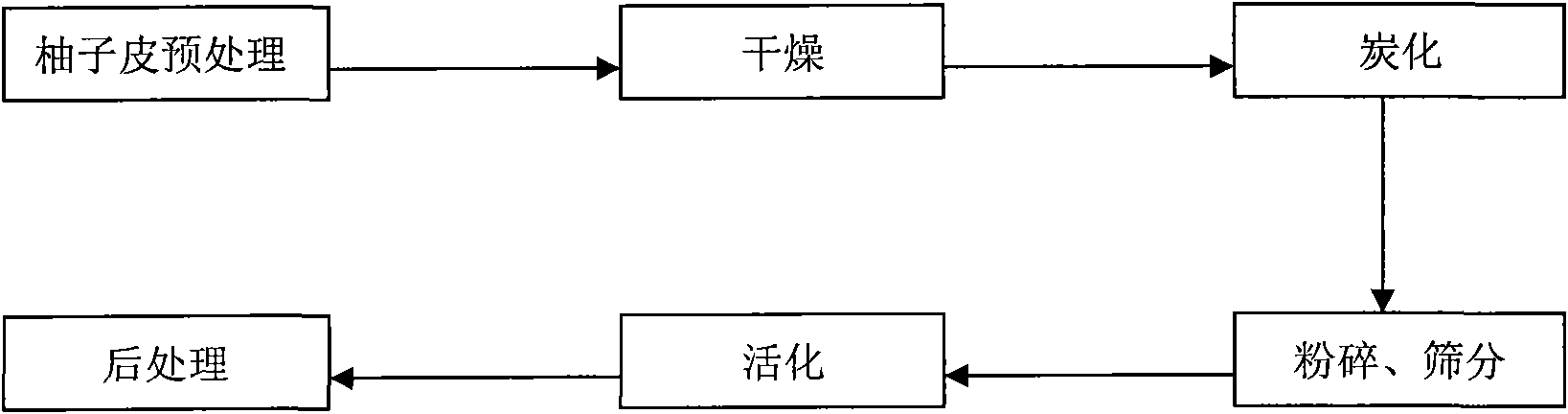

Method used

Image

Examples

Embodiment 1

[0016] Wash the pomelo peel to remove surface impurities, dry it at 110°C until the moisture content is 5%-10%, move it into a carbonization furnace, raise the temperature to 600°C, carbonize for 120 minutes under the condition of oxygen barrier, and pulverize to The scrap powder is mixed with KOH powder at a mass ratio of 1:1, put into an activation furnace, the temperature is programmed to 800°C, and activated for 240 minutes. The activated product is washed with water until neutral, and dried to obtain activated carbon from pomelo peel.

Embodiment 2

[0018] Wash the pomelo peel to remove surface impurities, dry it at 120°C until the moisture content is 5%-10%, move it into a carbonization furnace, raise the temperature to 500°C, carbonize for 120 minutes under the condition of oxygen barrier, and pulverize to The scrap powder is mixed with KOH powder according to the mass ratio of 1:2, put into the activation furnace, the temperature is programmed to 800°C, and activated for 240 minutes. The activated product is washed with HCl aqueous solution at pH 2-2.5 and temperature 95°C, and then separated from solid and liquid. Add water and stir well, put it into an ultrasonic oscillator and vibrate ultrasonically for 3 minutes, repeat the same method twice after suction filtration, wash until the pH is 6.5-7.0, and dry to get grapefruit peel activated carbon.

Embodiment 3

[0020] Wash the pomelo peel to remove surface impurities, dry it at 120°C until the moisture content is 5%-10%, move it into a carbonization furnace, raise the temperature to 600°C, carbonize for 120 minutes under the condition of oxygen barrier, and pulverize to The scrap powder is mixed with KOH powder at a mass ratio of 1:3, put into an activation furnace, the temperature is programmed to rise to 800°C, and activated for 240 minutes. The activated product is washed with water until neutral, and dried to obtain activated carbon from pomelo peel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com