Formula and film-coating preparation method for biological carbon coated urea

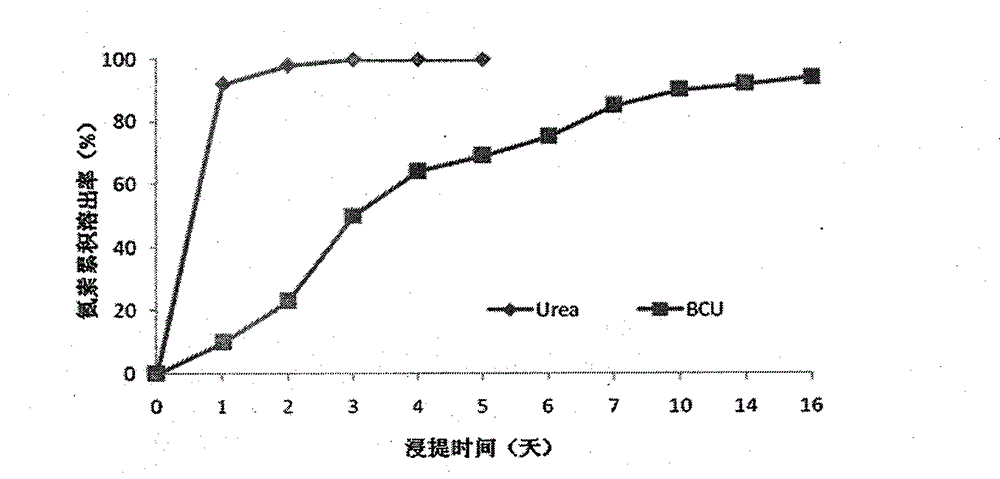

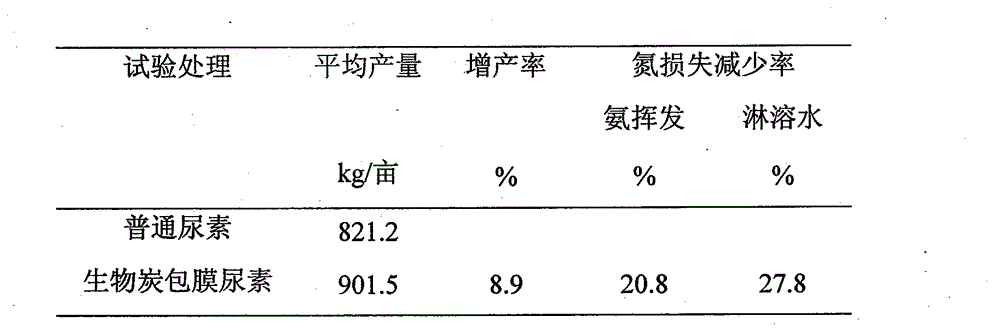

A technology of coated urea and biochar, which is applied in the fields of fertilizer mixture, agricultural gas emission reduction, climate change adaptation, etc., can solve the problems that have not been reported in agriculture, and achieve reduced fertilizer leaching, good slow-release effect, strong ion The effect of adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1. Using local agricultural waste, such as vegetables, flowers, and corn stalks as raw materials for biochar production, the raw materials are crushed, dried, and then carbonized at low temperature into 40kg of porous biochar;

[0042] 2. Mix the coating material made of 30kg biochar powder, 12kg sulfur powder, and 2kg dicyandiamide; make 3kg cornstarch into a bonding liquid, and 3kg bentonite as a bonding powder; use 50kg of large-grain urea as fertilizer The core is wrapped and granulated.

[0043] 3. The material wrapped and granulated by the disc granulator enters the dryer for drying, and after cooling and screening, the granular biochar-coated slow-release urea is 95kg, of which the total nutrient (N+P 2 o 5 +K 2 O) is 29.5kg, the total nitrogen content is 25kg, biochar is 28kg, and organic matter is 16.8kg.

[0044] Beneficial effects of the present invention are further elaborated below by test example:

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com