Improved sulfur coated thiourea slow release fertilizer and its manufacturing method

A technology of applying sulfur urea and slow-release fertilizer, which is applied in urea compound fertilizer, fertilizer mixture, nitrogen fertilizer, etc., can solve the problem of increased energy consumption, impact resistance and wear resistance of the coating of sealant-coated drum and conditioner-coated drum. It can reduce the energy consumption, good toughness and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

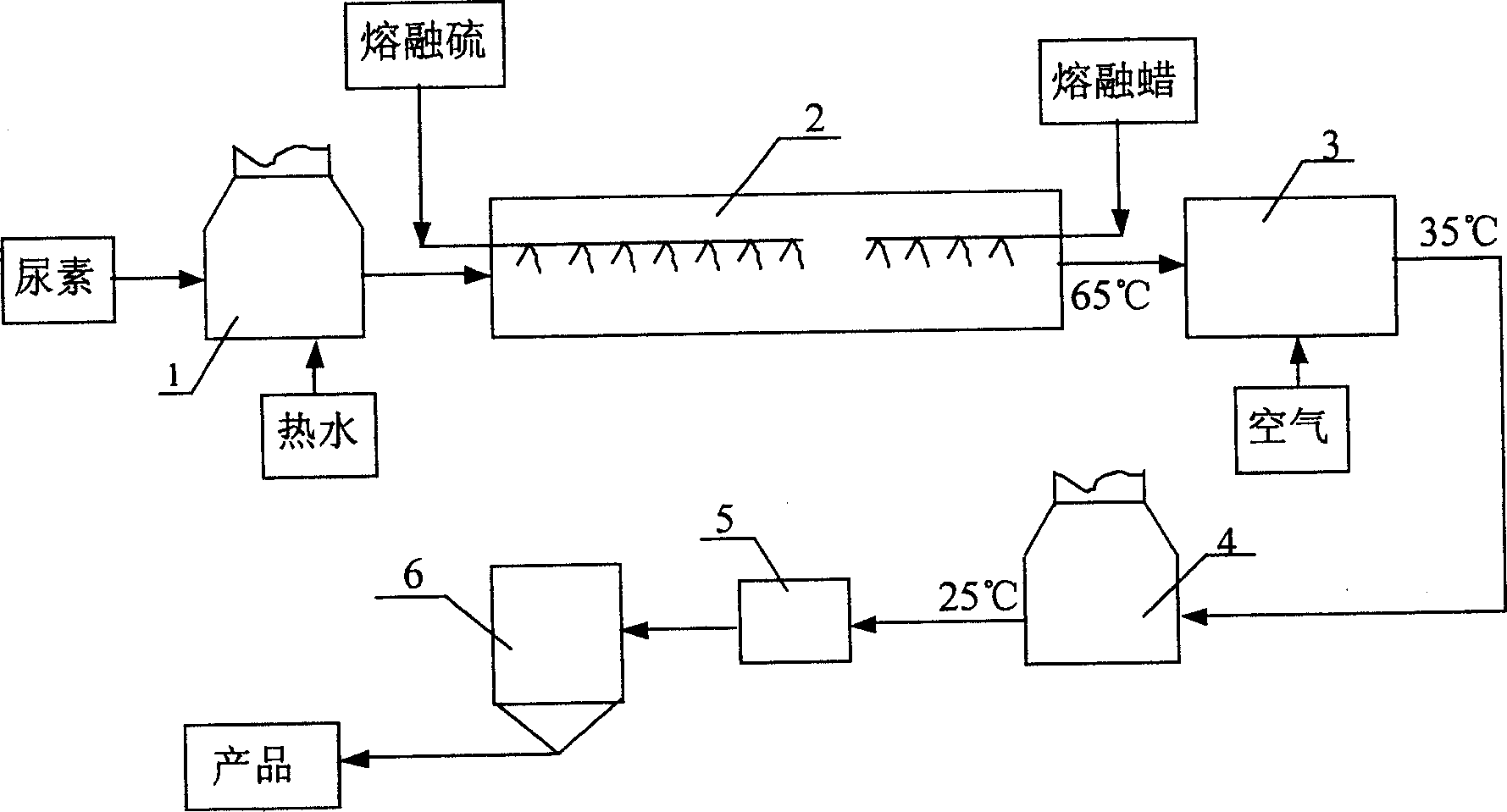

Embodiment 1

[0016] 740 grams of urea, preheated at 60°C, coated with 230 grams of sulfur and kept at 155°C, and then coated with 30 grams of EVACOTE produced by Canadian International Group in the same drum 7089, kept at 95°C for coating, then cooled to 35°C by fluidized bed cooler 1, and then cooled to 25°C by solid heat exchanger to obtain the finished product (34-0-0-23S).

Embodiment 2

[0018] 700 grams of urea, preheated at 60°C, coated with 270 grams of sulfur and kept at 155°C, and then coated with 30 grams of EVACOTE produced by Canadian International Group in the same drum 7089, kept at 95°C for coating, then cooled to 35°C by fluidized bed cooler 1, and then cooled to 25°C by solid heat exchanger to obtain the finished product (32-0-0-27S).

Embodiment 3

[0020] 740 grams of urea, preheated at 60°C, coated with 245 grams of sulfur and kept at 155°C, and then coated with 15 grams of EVACOTE produced by Canadian International Group in the same drum 7089, kept at 92°C for coating, then cooled to 35°C by fluidized bed cooler 1, and then cooled to 25°C by solid heat exchanger to obtain the finished product (34-0-0-24.5S).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com