Flour quality improver and preparation method thereof

A flour quality and improving agent technology, applied in the field of food processing, can solve the problems of high price, ineffectiveness, high energy consumption, etc., and achieve the effects of large processing capacity, good stability and high embedding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

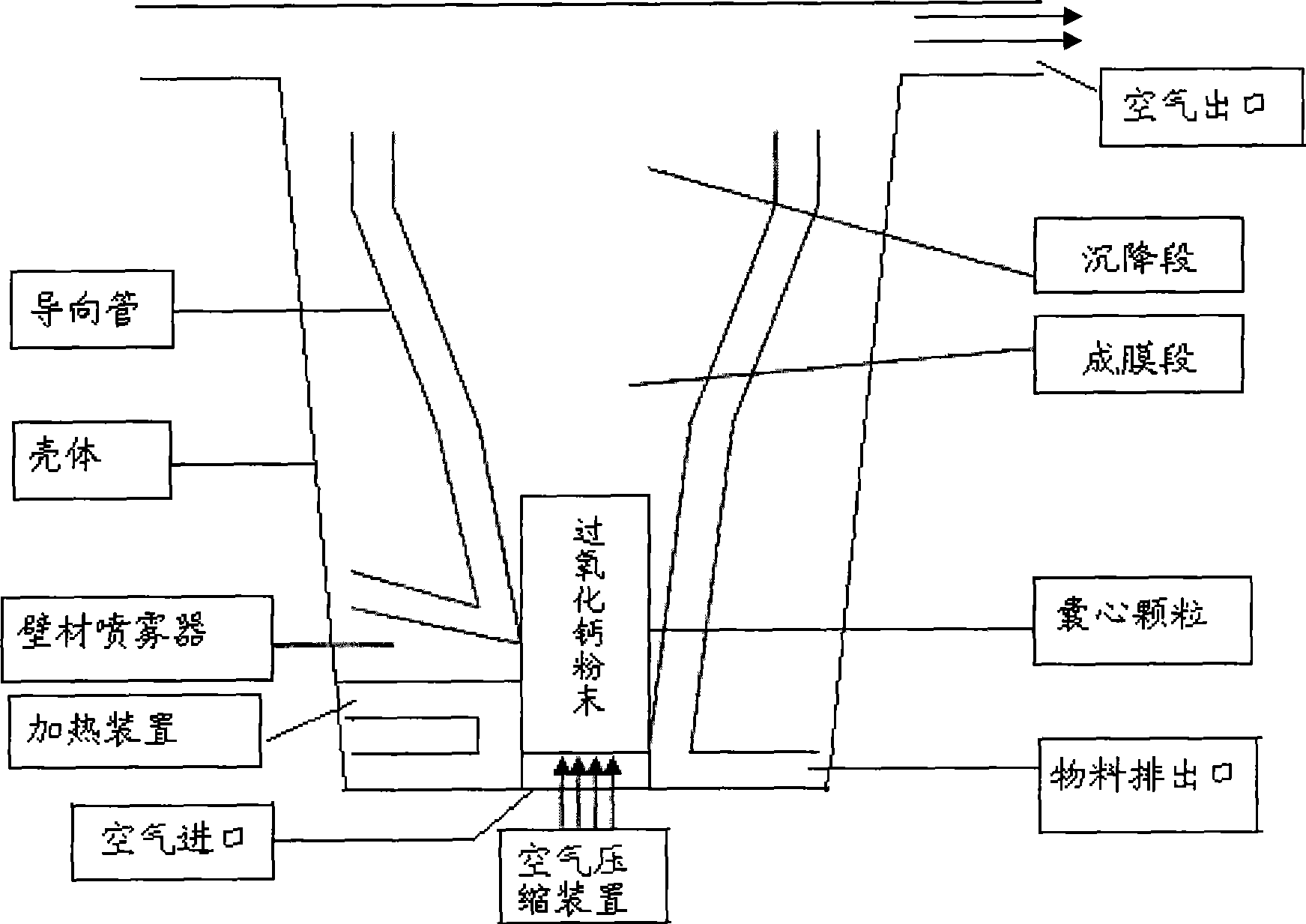

Image

Examples

Embodiment 1

[0037] Pass 1 kg of calcium peroxide powder through a 180-mesh sieve, suspend it in an air fluidized bed (diameter of the bed cavity is 600mm), and then dissolve 1 kg of paraffin wax, and use 2×10 5 The injection pressure of Pa and the flow rate of 30g / min are sprayed into the air fluidized bed through the atomizer. When all the paraffin is sprayed, the diameter of the microcapsules is about 0.28mm. Then, fill the air bed with liquid nitrogen and cool to -10°C, then discharge, pass through a 60-mesh sieve, inspect and pack.

[0038] The weight percent content of calcium peroxide in the product is 48%, and it is stored in a cool and dry place.

Embodiment 2

[0040] Pass 1 kilogram of calcium peroxide powder through a 170-mesh sieve, then suspend it in an air fluidized bed (diameter of the bed cavity is 600mm), and then dissolve 1.2 kilograms of octadecanoic acid in 3×10 5 The injection pressure of Pa and the flow rate of 30g / min are sprayed into the air fluidized bed through the atomizer. When all the octadecanoic acid is sprayed, the diameter of the microcapsules is about 0.25 mm. Next, fill the air bed with liquid nitrogen and cool to -5°C, then discharge, pass through a 60-mesh sieve, inspect, and pack.

[0041] The product calcium peroxide is 45% by weight and stored in a dry and cool place.

Embodiment 3

[0043] Pass 2 kg of calcium peroxide powder through a 150-mesh sieve, suspend it in an air fluidized bed (diameter of the bed cavity is 600mm), and then dissolve 3 kg of paraffin wax, and use 5×10 5 The spray pressure of Pa and the flow rate of 40g / min are sprayed into the air fluidized bed through the atomizer. When all the paraffin is sprayed, the diameter of the microcapsules is about 0.3mm. Then, fill the air bed with liquid nitrogen and cool to -7°C, then discharge, pass through a 60-mesh sieve, inspect and pack.

[0044] The weight percentage of the product calcium peroxide is 40%, and it is stored in a cool and dry place.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com