Acetic ester coated controlled-release urea fertilizer and preparation technique

A technology of acetate starch and controlled-release urea, which is applied in the direction of urea compound fertilizer, fertilizer mixture, nitrogen fertilizer, etc., can solve the problems of lower fertilizer nitrogen utilization rate, increase of soil pH value, easy leaching of nitrate nitrogen, etc., and achieve the goal of application The effect of improved effect, wide source and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

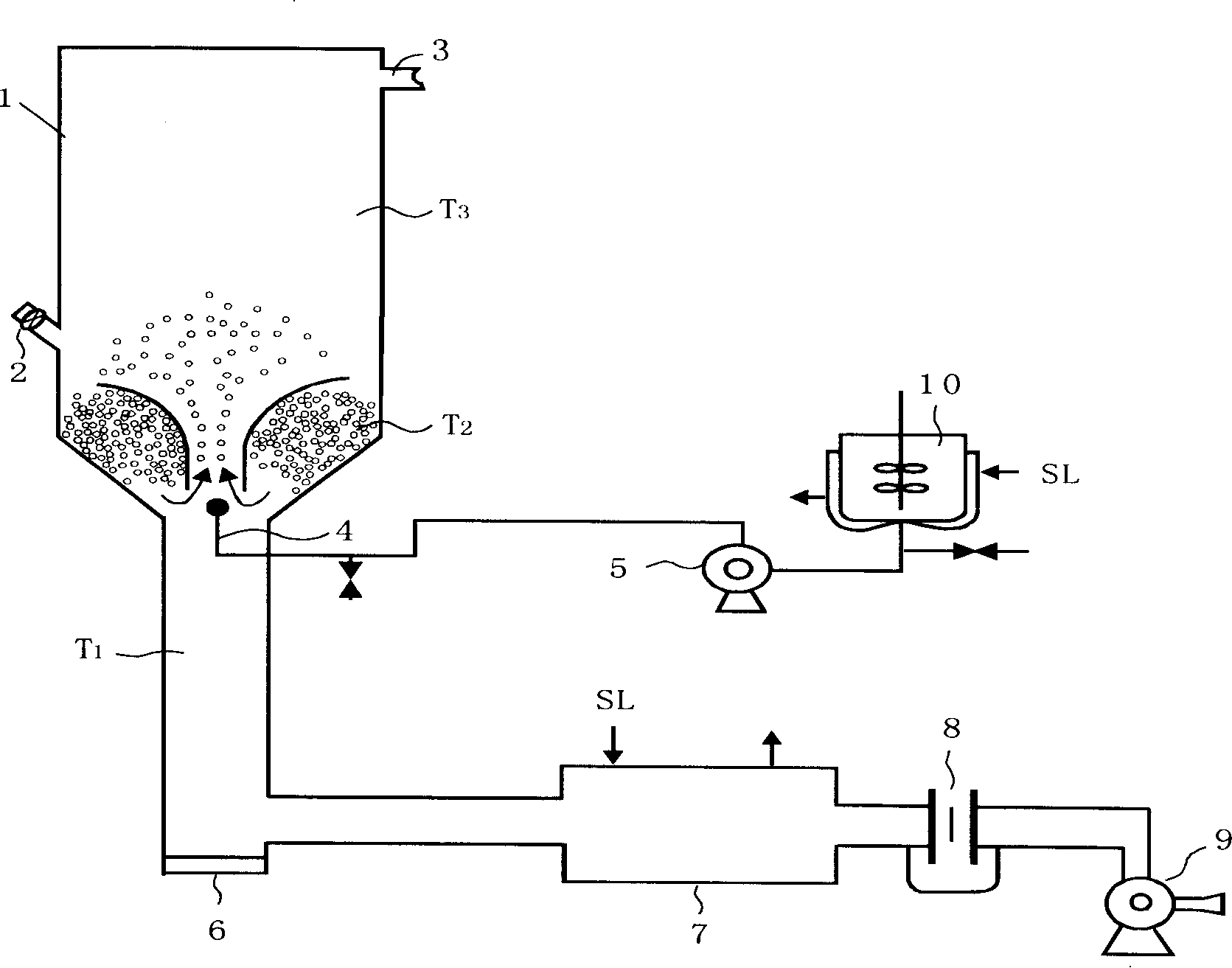

[0032] The preparation process of controlled-release urea: using fluidized bed coating technology, adding urease or / and nitrification inhibitor corresponding to the amount of urea to the corresponding binder composed of acrylic resin, ethyl cellulose copolymer and organic solvent In the process, after fully mixing uniformly, use a fluidized bed to spray on the surface of urea granules under the state of urea fluidization, and make up urease inhibitor NBPT or / and nitrification inhibitor DCD, acrylic resin and ethyl cellulose copolymer and organic solvent The mixed solution of the mixed solution is evenly coated on the surface of urea granules to form a smooth and uniform inhibitor coating layer to obtain the core of the controlled-release urea fertilizer. It can also directly coat the large granular urea to produce coated fertilizer.

[0033] Then the above-mentioned controlled-release urea fertilizer core is coated in a fluidized state, with acetate starch and ethyl cellulose ...

Embodiment 1

[0036] For every 100 parts of granular urea containing 46.3% nitrogen, 0.0625 parts of urease inhibitor N-butylthiophosphoric triamine (NBPT) and 2 parts of nitrification inhibitor dicyandiamide (DCD), 5 parts of acrylic resin and ethyl Cellulose copolymer, industrial ethanol solution 500ml. Dissolve the corresponding amount of acrylic resin and ethyl cellulose copolymer into industrial ethanol solution, and then mix the corresponding amount of urease inhibitor N-butylthiophosphate triamine (NBPT) and nitrification inhibitor dicyandiamide (DCD) After uniformity, add it and stir evenly to form a mixed suspension solution. The mixed suspension solution was coated with fluidized urea particles in a fluidized bed. The operating parameters of the fluidized bed were 60° C. of air inlet temperature, 0.35 Pa of compressed air pressure, and 0.05 Pa of nozzle atomization pressure to prepare urea fertilizer cores containing 43.2% nitrogen. Then put every 100 parts of urea fertilizer cor...

Embodiment 2

[0038] For every 100 parts of nitrogen-containing 46.3% granular urea, 1 part of urease inhibitor N-butylthiophosphoric triamine (NBPT), 5 parts of acrylic resin and ethyl cellulose copolymer, and 500 ml of industrial ethanol solution. A corresponding amount of acrylic resin and ethyl cellulose copolymer is dissolved in industrial ethanol solution, and then a corresponding amount of urease inhibitor N-butylthiophosphoric triamine (NBPT) is added therein and stirred evenly to form a mixed suspension solution. The mixed suspension solution is coated with fluidized urea particles in a fluidized bed. The operating parameters of the fluidized bed are as follows: inlet air temperature 60°C, compressed air pressure 0.35Pa, nozzle atomization pressure 0.05Pa. A urea fertilizer core containing 43.6% nitrogen was prepared. Then put every 100 parts of urea fertilizer core into the fluidized bed, use 20 parts of acetate starch and 10 parts of ethyl cellulose to form a copolymer, 1 part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com