Synchronous nutrient controlled release fertilizer special for cotton and application thereof

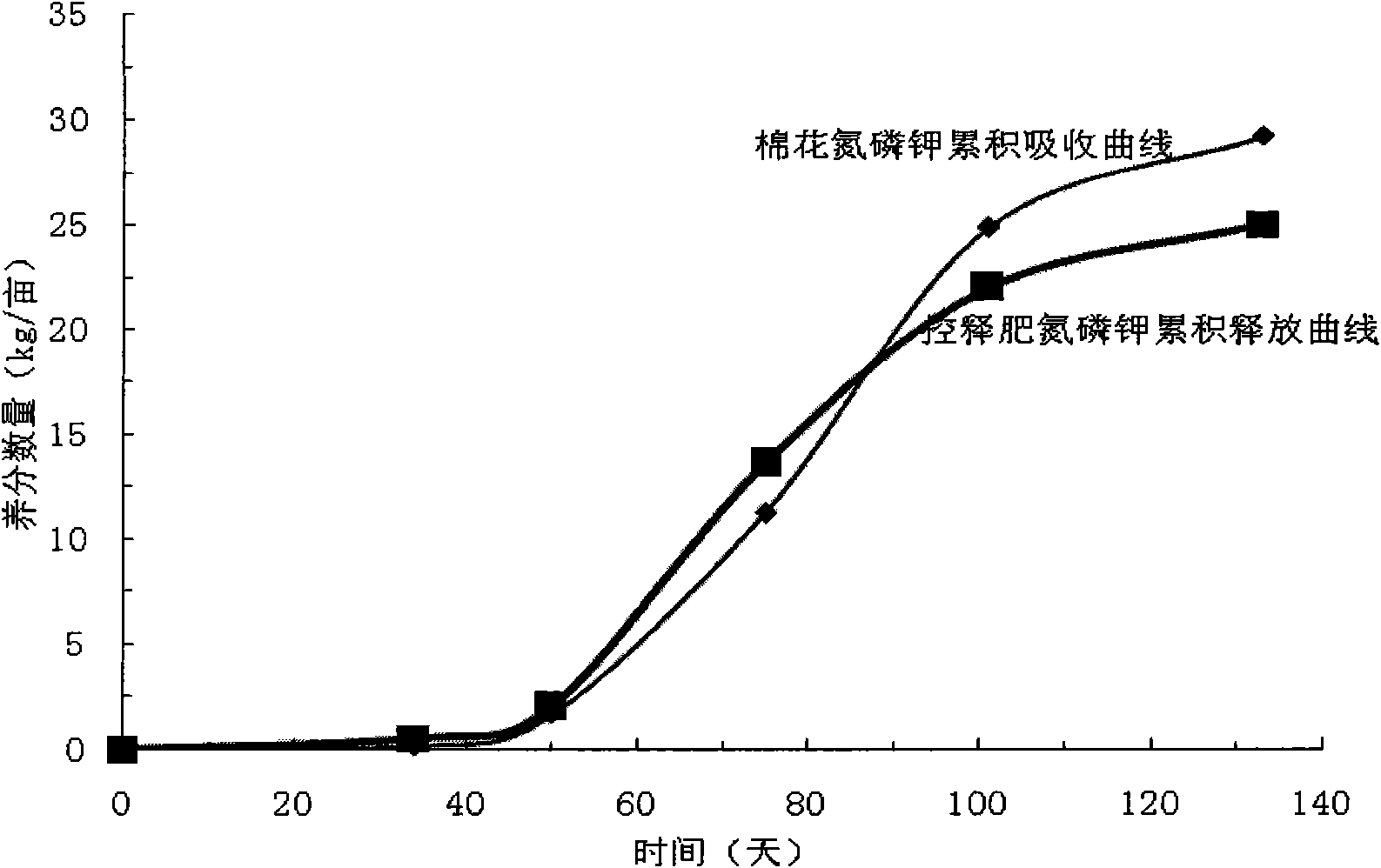

A controlled-release fertilizer and cotton technology, applied in the field of controlled-release fertilizers, can solve the problems of film shell rupture, sudden release of nutrients in the film, root burnt, etc., and achieve the effect of facilitating root absorption, improving fertilizer utilization rate, and less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Cotton-specific controlled-release fertilizer, the mass parts of raw material components are as follows:

[0046] Humic acid coated compound fertilizer 500kg,

[0047] Sulfur plus polymer coated urea 300kg,

[0048] 5% thermoplastic and thermosetting double-coated urea 120kg,

[0049] 6% thermoplastic and thermosetting double-coated urea 50kg,

[0051] Boric acid 10kg.

[0052] Preparation:

[0053] (1) Preparation of humic acid coated compound fertilizer:

[0054] Mix 10kg of epoxy resin and 1kg of triethylenetetramine evenly, and make it into a binder for later use.

[0055] Take 1000kg of compound fertilizer with a particle size of 2-3mm, preheat it to 65°C-70°C in a drum, spray 5kg of the above-mentioned binder on the rotating fertilizer particles, and then spray 25kg of air-dried and pulverized weathered coal to solidify Finally, repeat the above-mentioned process 1 time until the binder accounts for 1% of the core fertilizer mass, ...

Embodiment 2

[0064] Embodiment 2: special controlled-release fertilizer for cotton, raw material component mass parts are as follows:

[0065] Humic acid coated compound fertilizer 450kg,

[0066] Sulfur plus polymer coated urea 350kg,

[0067] 5% thermoplastic and thermosetting double-coated urea 97kg,

[0068] 6% thermoplastic and thermosetting double-coated urea 80kg,

[0070] Boric acid 8kg.

[0071] The raw material preparation method is the same as in Example 1.

Embodiment 3

[0072] Embodiment 3: special controlled-release fertilizer for cotton, raw material component mass parts are as follows:

[0073] Humic acid coated compound fertilizer 550kg,

[0074] Sulfur plus polymer coated urea 250kg,

[0075] 5% thermoplastic and thermosetting double-coated urea 110kg,

[0076] 6% thermoplastic and thermosetting double-coated urea 60kg,

[0077] Zinc sulfate 25kg,

[0078] Boric acid 5kg.

[0079] The raw material preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com