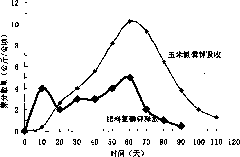

Seed-friendly corn-specific controlled-release fertilizer

A corn-specific and friendly technology, applied in application, fertilization devices, fertilizer mixtures, etc., can solve the problems of controlled release performance of fertilizers and violent fluctuations in nutrient release, and achieve the effect of good appearance, perfect combination, and not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Seed-friendly controlled-release fertilizer for corn, the raw material components are as follows:

[0055] Sulfur plus polymer coated urea 45 parts

[0056] Sulfur plus polymer coated potassium chloride 9 parts

[0057] 4.5% thermoplastic thermosetting double-coated urea 10 parts

[0058] 5.0% thermoplastic thermosetting double-coated urea 15 parts

[0059] 13 parts diammonium phosphate

[0060] Granular potassium chloride 5 parts

[0062] Preparation:

[0063] (1) Sulfur plus polymer coated urea and coated potassium chloride:

[0064] A, get 9 kilograms of novolak epoxy resins, 1 kilogram of triethylenetetramine, mix uniformly, be mixed with macromolecular polymer coating agent A.

[0065] B. Get 100 kilograms of granular urea and 100 kilograms of granular potassium chloride with a diameter of 2 to 4 millimeters respectively, and wrap a layer of sulfur according to the prior art. The percentage of sulfur membrane material accountin...

Embodiment 2

[0071] Embodiment 2: Seed-friendly controlled-release fertilizer for corn, the mass parts of raw material components are as follows:

[0072] Sulfur plus polymer coated urea 35 parts

[0073] Thirteen parts of sulfur plus polymer coated potassium chloride

[0074] 4.5% thermoplastic thermosetting double-coated urea 15 parts

[0075] 5.0% thermoplastic thermosetting double-coated urea 10 parts

[0076] 17 parts diammonium phosphate

[0077] Granular potassium chloride 8 parts

[0079] The raw material preparation method is the same as in Example 1.

Embodiment 3

[0080] Embodiment 3: Seed-friendly controlled-release fertilizer for corn, the mass parts of raw material components are as follows:

[0081] Sulfur plus polymer coated urea 38 parts

[0082] Sulfur plus polymer coated potassium chloride 11 parts

[0083] 4.5% thermoplastic thermosetting double-coated urea 12 parts

[0084] 5.0% thermoplastic thermosetting double-coated urea 13 parts

[0085] 15 parts diammonium phosphate

[0086] Granular potassium chloride 7 parts

[0087] Zinc sulfate 4 parts.

[0088] The raw material preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com