Rice special controlled-release fertilizer applied once in processes of rice transplantation and seedling culture and preparation method thereof

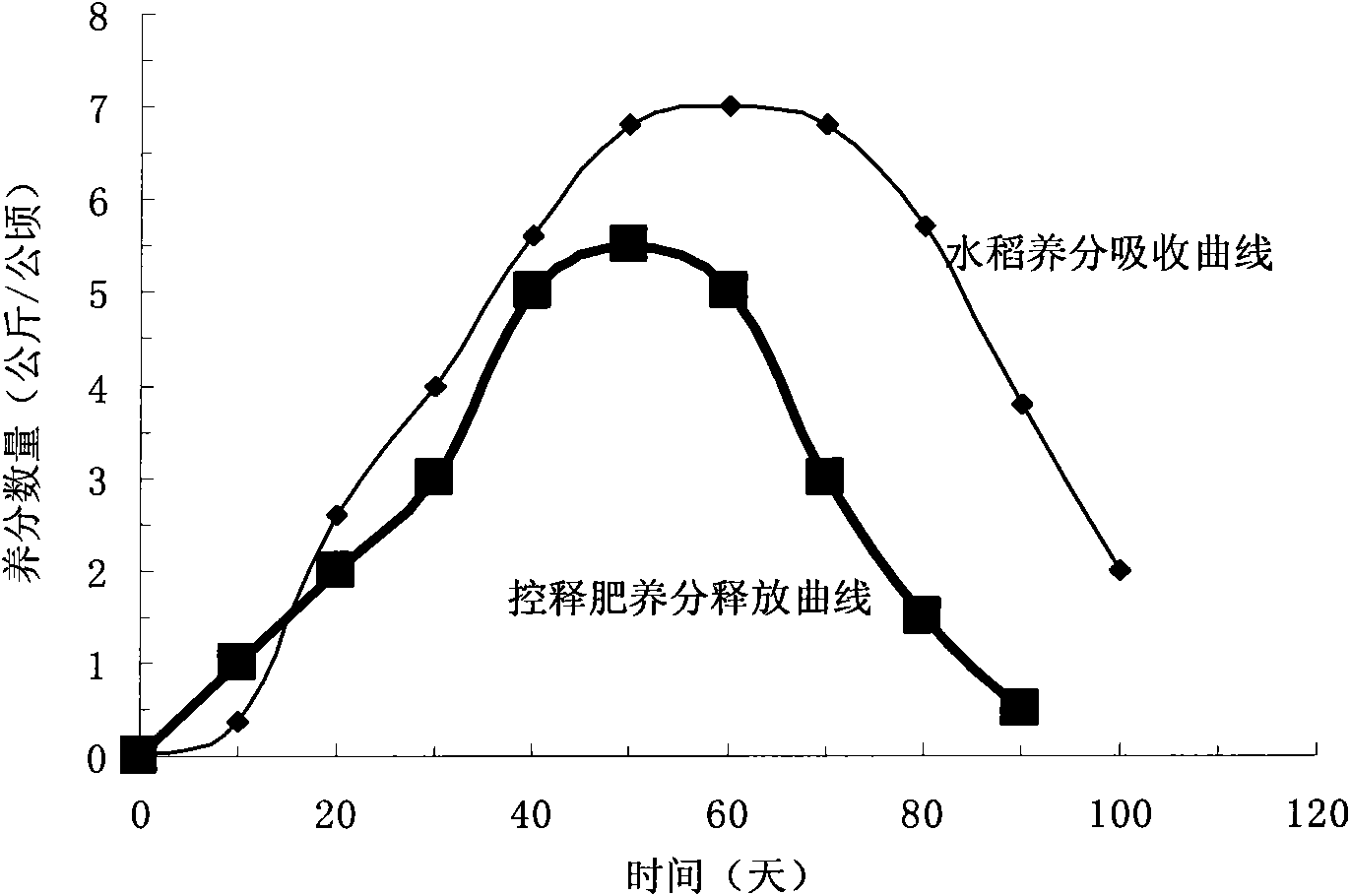

A technology of controlled-release fertilizer and rice, which is applied in the direction of fertilization device, application, fertilizer mixture, etc., can solve the problems of burning seeds or roots, membrane shell rupture, and inability to combine application, etc., so as to reduce the amount of fertilizer, facilitate root system absorption, and improve The effect of fertilizer use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Special controlled-release fertilizer for rice, the mass parts of raw material components are as follows:

[0036] Sulfur plus polymer coated urea 26 parts

[0037] 30 parts of sulfur plus polymer coated compound fertilizer

[0038] 6% thermoplastic and thermosetting double-coated urea 15 parts

[0039] Humic acid coated compound fertilizer 25 parts

[0041] Preparation:

[0042] (1) Preparation of sulfur-added polymer-coated urea and sulfur-added polymer-coated compound fertilizer:

[0043] A, 9 kilograms of novolac epoxy resins and 1 kilogram of triethylenetetramine are mixed, and are mixed with polymer coating agent.

[0044] B, take by weighing 100 kilograms of granular urea of 2~3 millimeters in particle diameter, 100 kilograms of granular compound fertilizers of 2~4 millimeters in particle diameter, wrap one deck sulfur earlier respectively by prior art, sulfur membrane material accounts for 20% of nuclear fertilizer quality, ...

Embodiment 2

[0053] Embodiment 2: special controlled-release fertilizer for rice, the mass parts of raw material components are as follows:

[0054] Sulfur plus polymer coated urea 22 parts

[0055] Sulfur plus polymer coated compound fertilizer 25 parts

[0056] 6% thermoplastic and thermosetting double-coated urea 20 parts

[0057] Humic acid coated compound fertilizer 30 parts

[0059] The raw material preparation method is the same as in Example 1.

Embodiment 3

[0060] Embodiment 3: special controlled-release fertilizer for rice, the mass parts of raw material components are as follows:

[0061] Sulfur plus polymer coated urea 30 parts

[0062] 28 parts of sulfur plus polymer coated compound fertilizer

[0063] 6% thermoplastic and thermosetting double-coated urea 18 parts

[0064] Humic acid coated compound fertilizer 22 parts

[0065] Zinc sulfate 2 parts.

[0066] The raw material preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com