Slow-release compound fertilizer for mechanical transplanting of rice seedlings

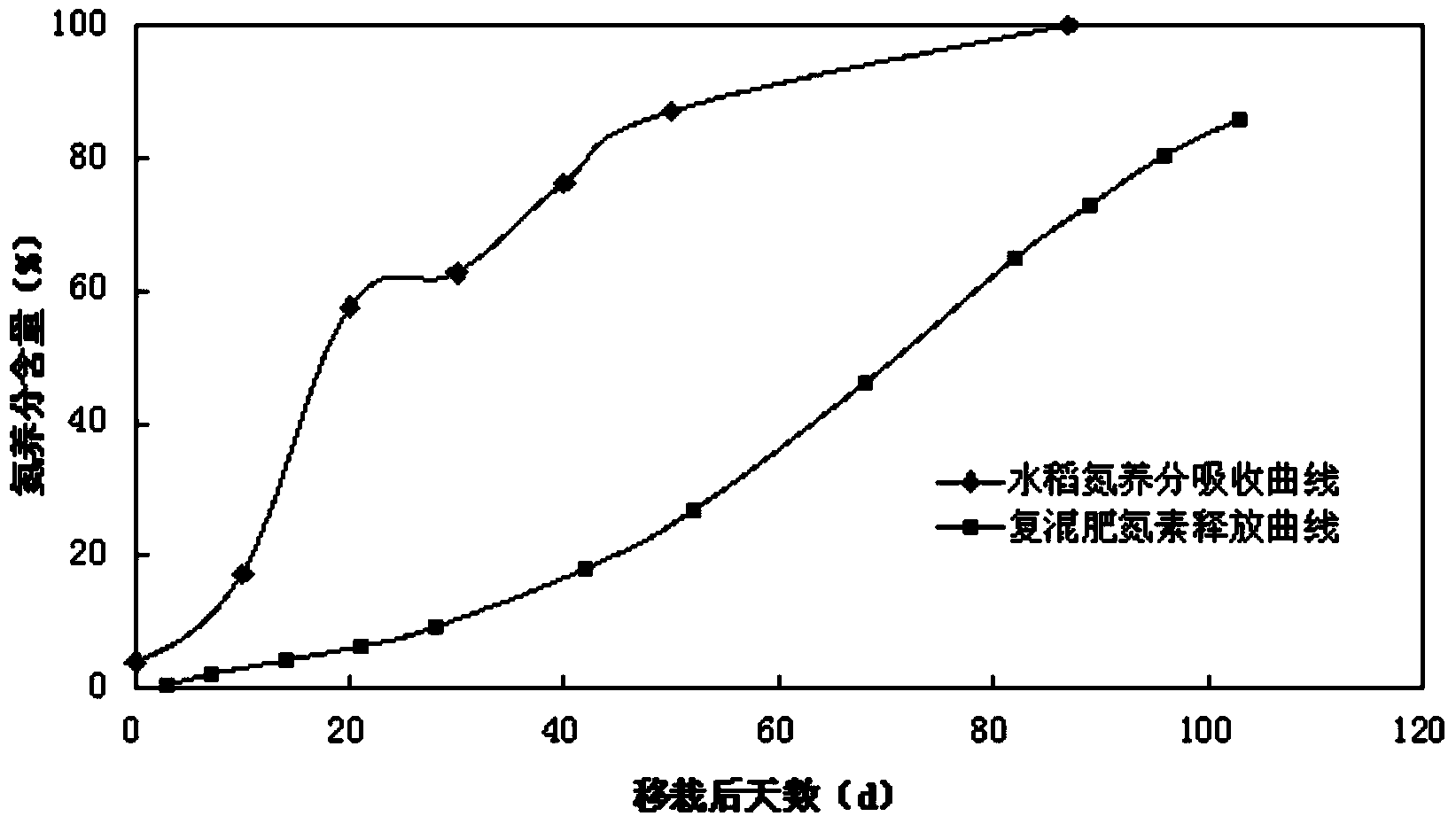

A technology of slow-release compound fertilizer and rice machine, which is applied in application, fertilization method, fertilization device, etc. It can solve the problems of fertilizer supply quantity, speed and crop demand being out of sync, inconvenient rice mechanized fertilization operation, high nitrogen fertilizer utilization rate, etc. , to achieve the effect of saving labor cost of fertilization, prolonging the time of fertilization and long fertilizer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

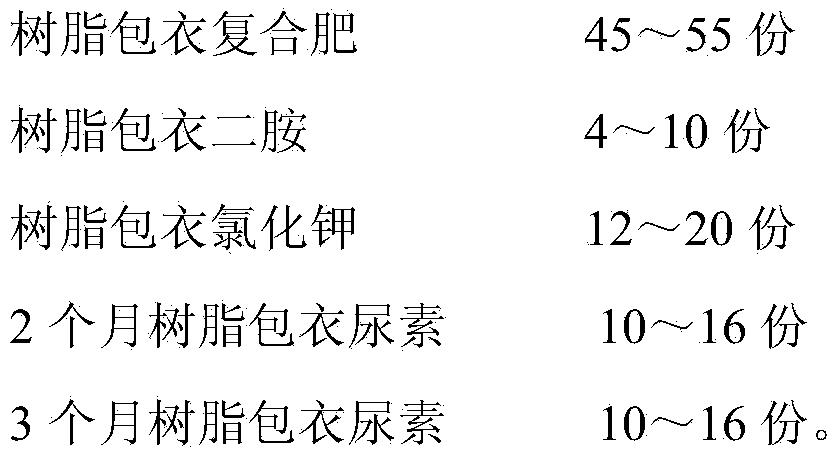

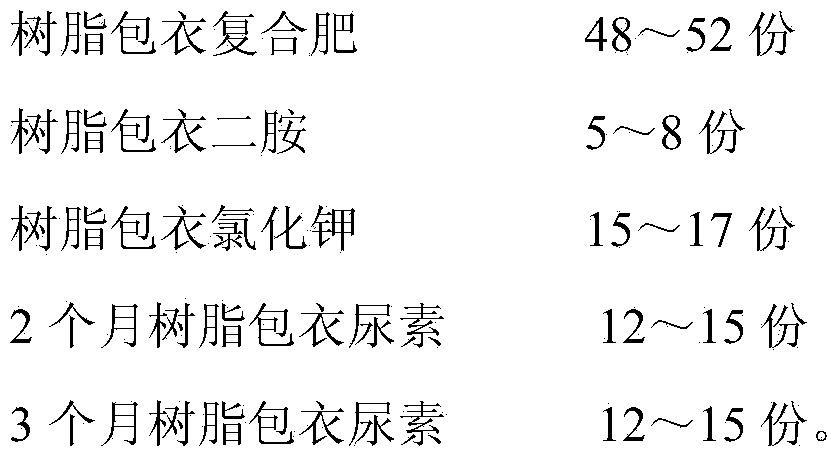

[0031] Embodiment: The mass parts of each coated slow-release component in the slow-release compound fertilizer are as follows:

[0032]

[0033] The values in the parentheses of the above components are the common identifications of the core fertilizer nutrient content in fertilizers, that is, the mass percentages of N, P, and K (in terms of N, P 2 O 5 , K 2 O meter); the above 2 months and 3 months resin-coated urea refer to controlled-release fertilizers whose nutrient supply period or fertilizer effect period are 50-60 days and 80-90 days respectively.

[0034] The nutrient ratio of the present embodiment slow-release compound fertilizer is 1: 0.5: 0.8 (referring to N: P 2 O 5 : K 2 O mass ratio), the amount of fertilization is based on the amount of nitrogen applied, and the total amount of nitrogen applied is 15kg / mu. The method of fertilization is: use slow-release compound fertilizer as the base fertilizer, apply Jingguan PZP-80 pot seedling planting machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com