Compound fertilizer containing humus acid and preparation process thereof

A technology of compound fertilizer and humic acid, which is applied in urea compound fertilizer, ammonium orthophosphate fertilizer, layered/coated fertilizer, etc., can solve the problems of orderly and stable fertilizer release rate, difficulty in obtaining materials, and high cost. , to avoid environmental pollution and soil agglomeration, low cost, and improve the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A compound fertilizer containing humic acid, which comprises the following raw materials: coated carrier, urea, monoammonium phosphate, potassium chloride, humic acid, water, and biological agents.

[0028] Specifically, the enveloped carrier is prepared according to the following method:

[0029] Add polybutylene succinate to chloroform, the ratio of polybutylene succinate and chloroform is 1g: 10ml, stir until dissolved, then add one-tenth of polybutylene succinate Parts by weight of starch ether, stirred at 200 rpm for 10 minutes, then added ethanol with the same volume as chloroform, allowed to stand for 30 minutes, collected the precipitate, put it in a freeze dryer, and dried for 12 hours to obtain the product.

[0030] The biological preparation is prepared according to the following method:

[0031] Paenibacillus polymyxa, Trichoderma harzianum, Bacillus megaterium and Azotobacter torus were cultured to a concentration of 1×10 9 The bacterial liquid of cfu / ml ...

Embodiment 2

[0037] A compound fertilizer containing humic acid, which comprises the following raw materials: coated carrier, urea, monoammonium phosphate, potassium chloride, humic acid, water, and biological agents.

[0038] Specifically, the enveloped carrier is prepared according to the following method:

[0039] Add polybutylene succinate to chloroform, the ratio of polybutylene succinate and chloroform is 1g: 10ml, stir until dissolved, then add one-tenth of polybutylene succinate Parts by weight of starch ether, stirred at 200 rpm for 10 minutes, then added ethanol with the same volume as chloroform, allowed to stand for 30 minutes, collected the precipitate, put it in a freeze dryer, and dried for 12 hours to obtain the product.

[0040] The biological preparation is prepared according to the following method:

[0041] Paenibacillus polymyxa, Trichoderma harzianum, Bacillus megaterium and Azotobacter torus were cultured to a concentration of 1×10 9cfu / ml of bacterial liquid, and ...

Embodiment 3

[0049] 1. Urea release time test:

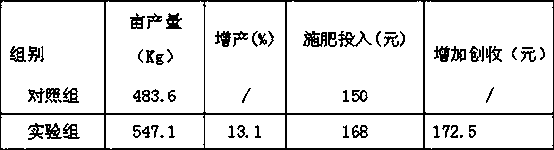

[0050] The test group is Example 1; the control group: the coated carrier prepared in Comparative Example 1 is used, and the rest are the same as Example 1. The test soil is ordinary soil with a water content of 30%, and the fertilizer depth is 15cm. The specific results are shown in Table 1:

[0051] Table 1

[0052] Release rate%

[0053] As shown in Table 1, the release rate of urea in the control group was faster, and all releases were completed within 16 days, while the release rate of urea in the test group was stable and orderly, which was basically synchronized with the absorption of crop nutrients, avoiding the excessive release of most slow-release fertilizers in the early stage. The defect of rapid mass loss, the effect is obviously better than that of chitosan-coated carrier.

[0054] 2. Degradation time test of the coated carrier:

[0055] The test group is the embodiment 1; the control group 1: no compound bacteri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com