A kind of method that utilizes glutamic acid waste water to produce liquid fertilizer

A technology of liquid fertilizer and glutamic acid, which is applied in the direction of sewage/sludge fertilizer, organic fertilizer, fertilizer mixture, etc., can solve the problems of not particularly obvious effect, single component of inorganic fertilizer, and high price, so as to lock nutrients and control loss, The effect of delaying the release of nutrients and the simple and feasible preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method utilizing glutamic acid waste water to produce liquid fertilizer, it comprises the steps:

[0026] Step 1) Filtration of fermentation broth: the glutamic acid fermentation broth is sterilized by microfiltration membrane filtration, and the retentate and filtrate are collected respectively; The retentate and concentrated liquid are combined into feed liquid A for later use; among them, the microfiltration membrane is an inorganic ceramic membrane with a molecular weight cut-off of 2000MW and a microfiltration temperature of 40°C; the ultrafiltration membrane has a molecular weight cut-off of 300MW and an ultrafiltration temperature of 40°C;

[0027] Step 2) Decolorization, concentration and crystallization: The permeate obtained in step (1) is pumped into the decolorization tank for decolorization treatment, and 0.5% activated carbon of the permeate mass is added to the decolorization tank, and the temperature in the decolorization tank is controlled at 45°C. Aft...

Embodiment 2

[0032] A method utilizing glutamic acid waste water to produce liquid fertilizer, it comprises the steps:

[0033] Step 1) Filtration of fermentation broth: the glutamic acid fermentation broth is sterilized by microfiltration membrane filtration, and the retentate and filtrate are collected respectively; The retentate and concentrated liquid are combined into feed liquid A for later use; among them, the microfiltration membrane is an inorganic ceramic membrane with a molecular weight cut-off of 2000MW and a microfiltration temperature of 40°C; the ultrafiltration membrane has a molecular weight cut-off of 300MW and an ultrafiltration temperature of 40°C;

[0034] Step 2) Decolorization, concentration and crystallization: The permeate obtained in step (1) is pumped into the decolorization tank for decolorization treatment, and 0.5% activated carbon of the permeate mass is added to the decolorization tank, and the temperature in the decolorization tank is controlled at 45°C. Aft...

Embodiment 3

[0039] Fertilizer effect test of fertilizer of the present invention

[0040] 1. Take tomato as an example:

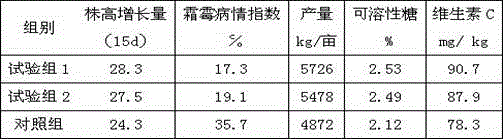

[0041] Effect of the liquid fertilizer prepared in Example 1 of the present invention on tomato yield and quality. The test group additionally sprays the preparation of the present invention, and the matched group is sprayed with equal amount of clear water. The tomato variety is ginkgo strong, 100kg per mu of land, and the two groups of other planting conditions are identical. The results are shown in Table 1. The application of this product can increase tomato yield, shorten the time to market, enhance tomato disease resistance, improve fruit quality, and increase the economic value of tomato fruit.

[0042] Table 1

[0043]

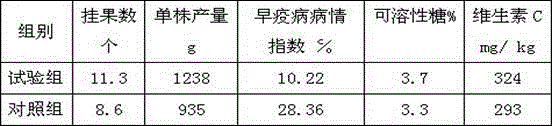

[0044] 2. Take cucumber as an example:

[0045] Effect of the liquid fertilizer of Example 1 of the present invention on cucumber yield and quality. The variety of cucumber tested in the spring greenhouse was Jinchun No. 3, which was cul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com