Method for preparing graphene-coated carbon microsphere material by coating graphene oxide on carbon microsphere

A technology of graphene coating and carbon microspheres, which is applied in the direction of electrical components, battery electrodes, circuits, etc., can solve the problems of high cost investment, high cost, and difficulty in large-scale production of carbon sphere three-dimensional structures, and achieve a wide range of applications. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

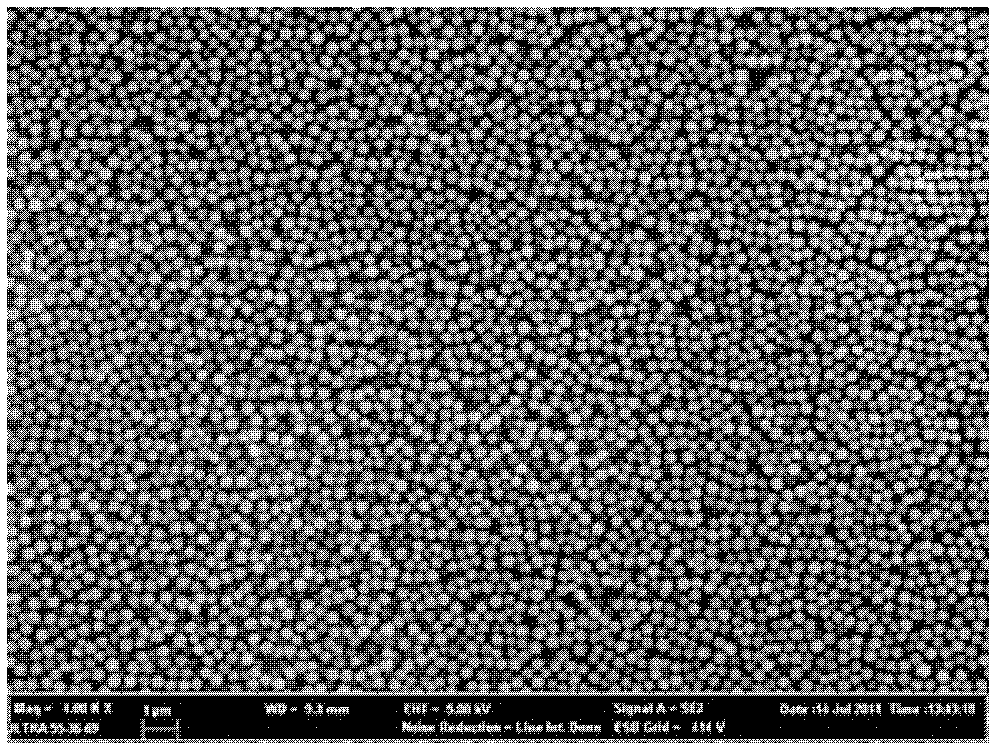

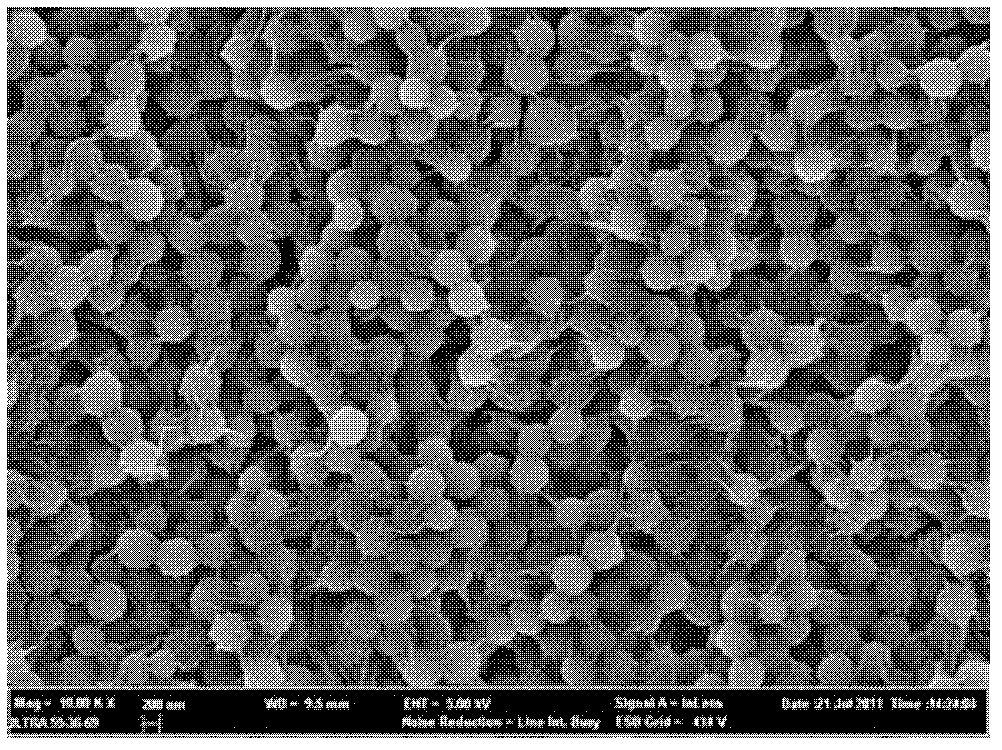

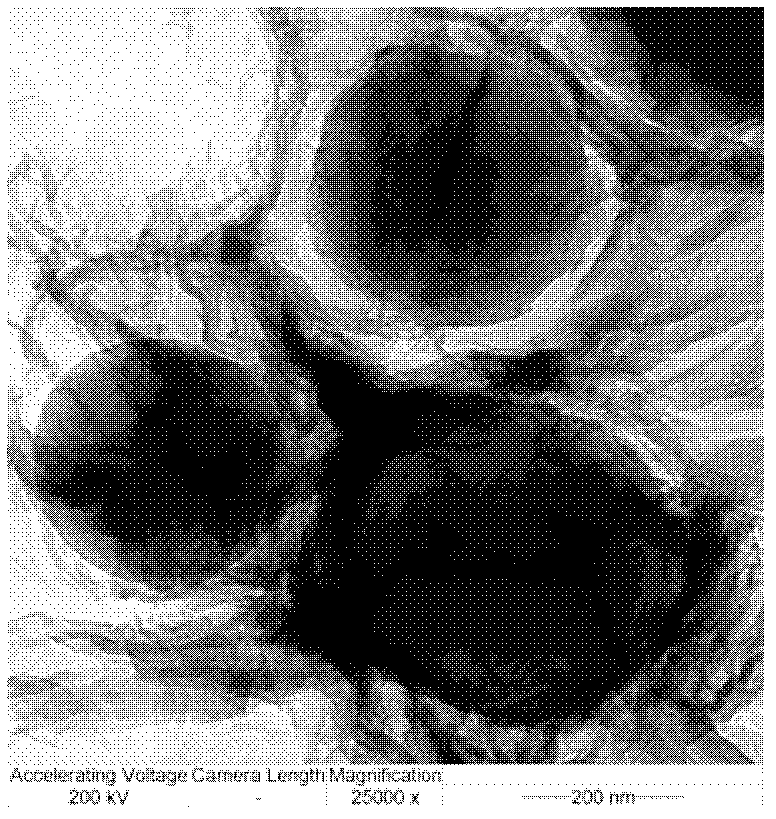

[0028] Preparation of carbon microspheres: at room temperature, using deionized water as a solvent, 5 g of glucose and 0.2 g of glutaric acid were made into 40 ml of a clear solution, placed in a reaction kettle with polytetrafluoroethylene as a liner, and heated to Maintain at 180°C for 5 hours, stop heating, and after the reaction kettle is cooled to room temperature, centrifuge the dark brown mixture obtained from the reaction to remove the supernatant; wash and centrifuge the product alternately with water and ethanol for several times until the supernatant until the liquid is colorless and transparent. The final centrifuged product was dried in an oven at 80° C. for 8 hours to finally obtain a dry carbon microsphere product.

[0029] Preparation of graphene oxide dispersion: add 0.2 g of dry graphite oxide to 200 ml of deionized water, and ultrasonicate for 30 minutes to obtain a stable and uniform yellow-brown graphene oxide dispersion with a concentration of 1 mg per ml...

Embodiment 2

[0033] Preparation of carbon microspheres: at room temperature, using deionized water as a solvent, 5 grams of sucrose and 0.2 grams of boric acid were made into 40 ml of a clear solution, placed in a polytetrafluoroethylene-lined reactor, and heated to 120 ° C Maintain under the conditions for 10 hours, stop heating, and after the reaction kettle is cooled to room temperature, centrifuge the dark brown mixed solution obtained from the reaction to remove the supernatant; wash and centrifuge the product in alternating order of water and ethanol for several times until the supernatant is free of until the color is transparent. The final centrifuged product was dried in an oven at 80° C. for 8 hours to finally obtain a dry carbon microsphere product.

[0034] Preparation of graphene oxide dispersion: add 0.2 g of dry graphite oxide to 200 ml of deionized water, and ultrasonicate for 30 minutes to obtain a stable and uniform yellow-brown graphene oxide dispersion with a concentrat...

Embodiment 3

[0038] Preparation of carbon microspheres: at room temperature, using deionized water as a solvent, 5 g of starch and 0.2 g of hydrochloric acid were made into 40 ml of a clear solution, placed in a polytetrafluoroethylene-lined reactor, and heated to 150 ° C Maintain under the conditions for 7 hours, stop heating, and after the reaction kettle is cooled to room temperature, centrifuge the dark brown mixed solution obtained from the reaction to remove the supernatant; wash and centrifuge the product in the order of alternating water and ethanol for several times until the supernatant is free of until the color is transparent. The final centrifuged product was dried in an oven at 40° C. for 16 hours to finally obtain a dry carbon microsphere product.

[0039] Preparation of graphene oxide dispersion: 0.16 g of dry graphite oxide was added to 200 ml of deionized water, and ultrasonicated for 30 minutes to obtain a stable and uniform yellow-brown graphene oxide dispersion with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com