Method and system for reducing splash in gas shielded welding of short-circuiting transfer

A technology of gas shielded welding and short-circuit transition, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of difficult current waveform, synchronization, and rapid drop speed of liquid bridge current, and achieve the effect of reducing welding spatter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

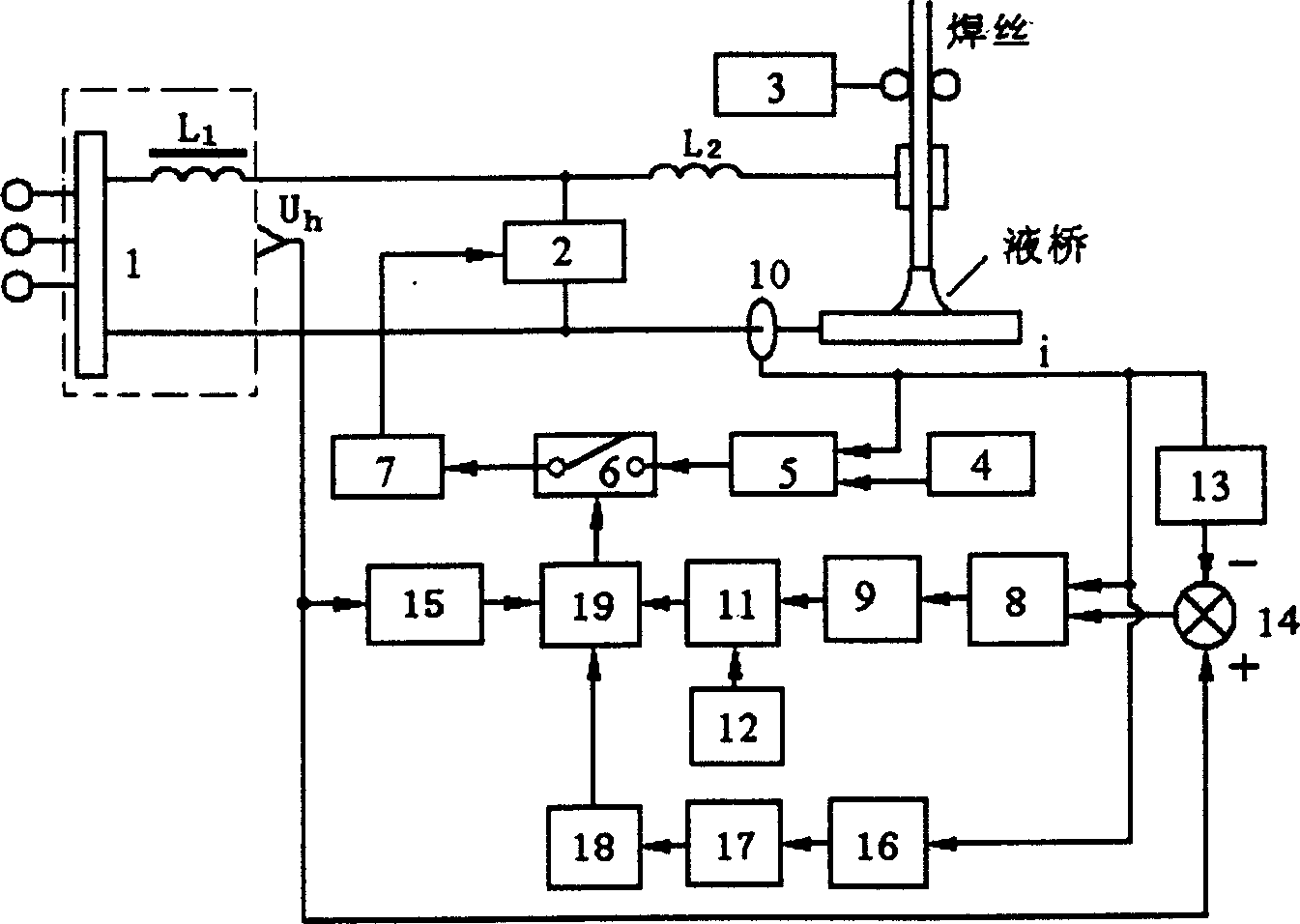

[0084] Figure 8 It is the basic circuit diagram of the detection and judgment system for the shrinkage state of the short-circuit liquid bridge. Its function is to detect the state of the shrinkage process of the welding short-circuit liquid bridge, and use the resistance change rate of the welding circuit or the impedance change rate of the welding circuit to characterize the shrinkage degree of the short-circuit liquid bridge or the liquid bridge diameter. And by comparing with the set value, when it reaches the set value, a trigger pulse is generated to open the short-circuit liquid bridge current closed-loop bypass control system.

[0085] The working principle of the circuit is as follows:

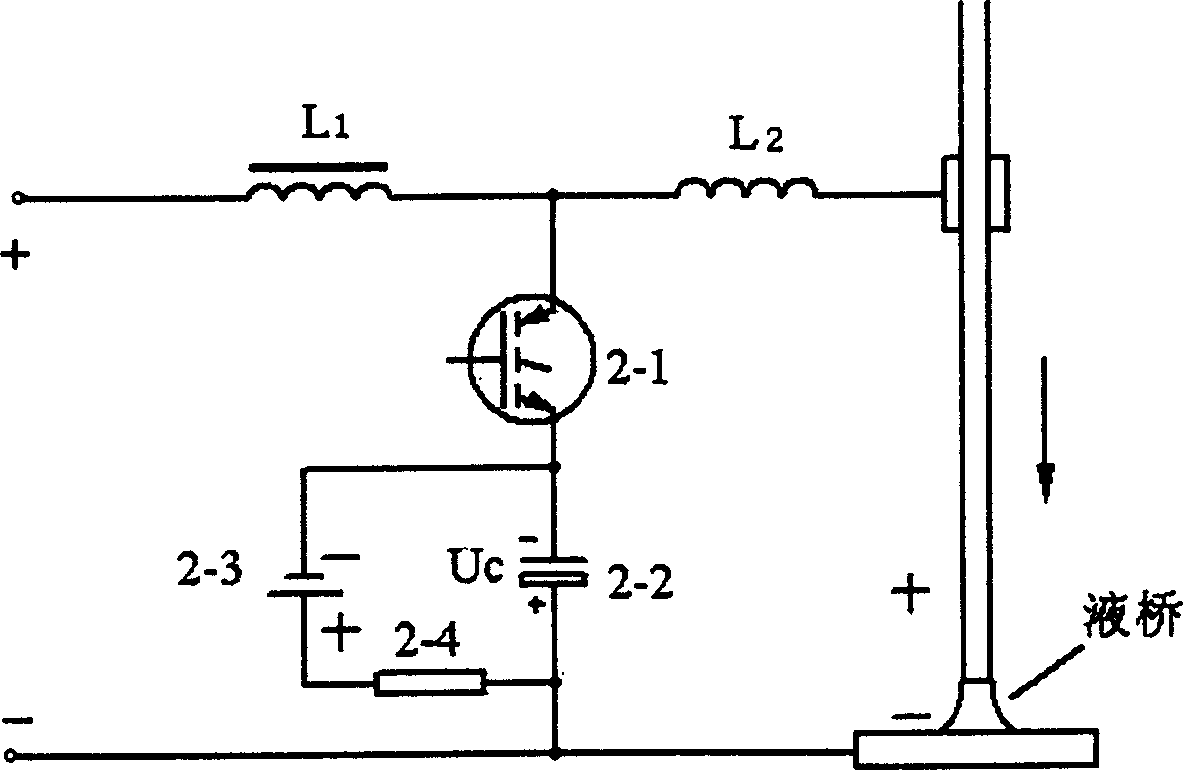

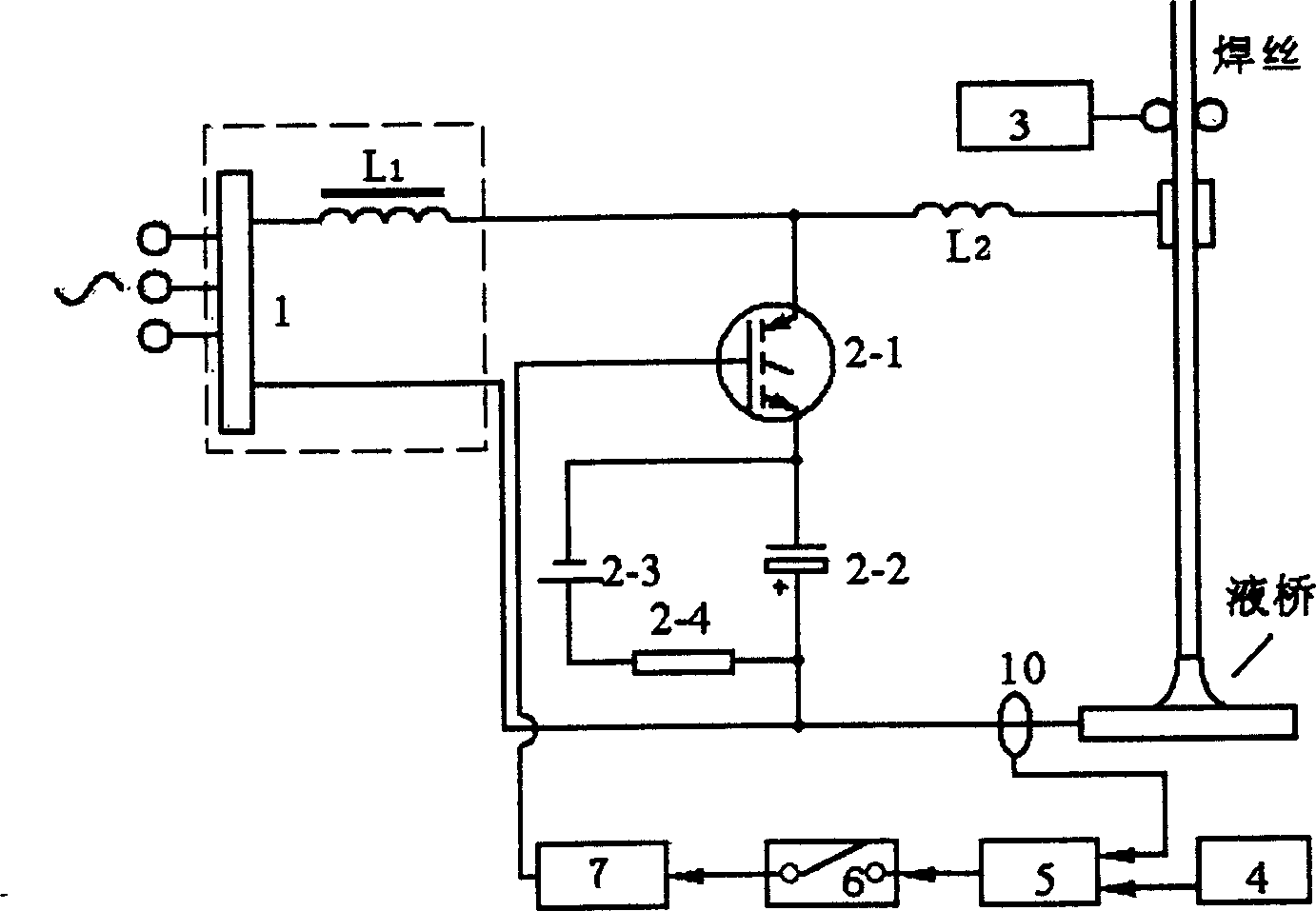

[0086] The voltage u is taken from Figure 9 The output voltage of the power supply of the welding machine in , the liquid bridge current i is taken from the current transformer of the welding circuit. Because the output voltage u of the power supply of the welding machine is not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com