Laser scanning-TIG composite melting strip welding method

A laser scanning and welding method technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of poor gap adaptability, high assembly accuracy requirements, unstable welding process, etc., to reduce assembly accuracy and enhance stirring. The effect of improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments.

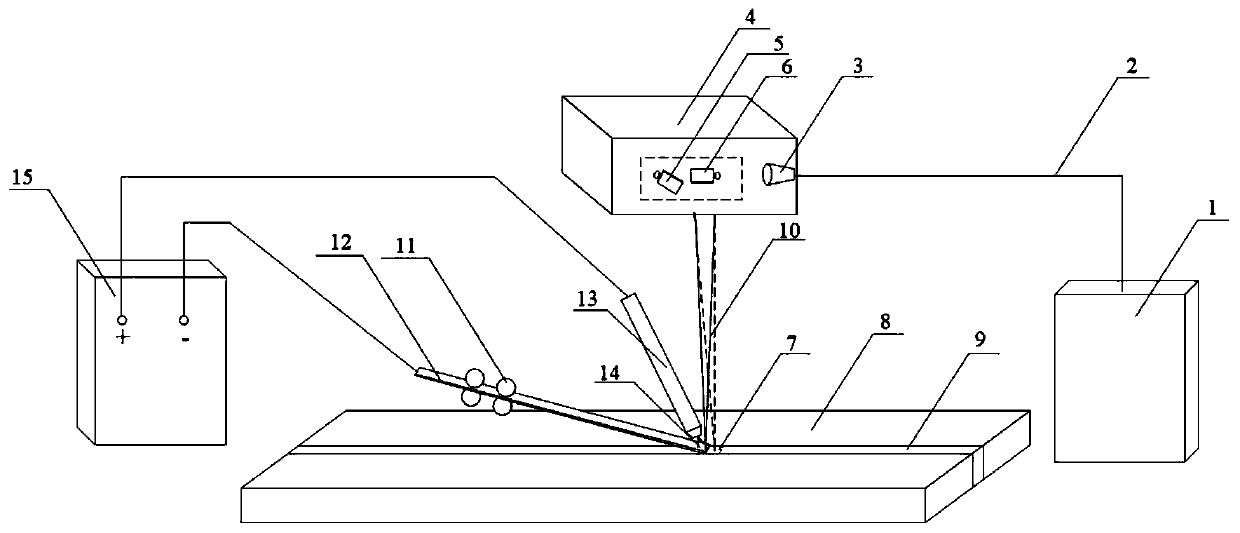

[0026] A laser scanning-TIG composite melting ribbon welding method, which is realized by laser scanning and TIG welding composite melting ribbon, is characterized in that it includes:

[0027] When welding, use a strip-shaped welding wire with a rectangular cross-section. The belt-feeding mechanism sends the strip-shaped welding wire above the gap between the workpieces to be welded. The width direction of the strip-shaped welding wire forms a certain angle with the welding direction. The ribbon welding wire is connected to the negative electrode o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com