Method for improving compactness of 3D (three dimensional) printing metal part by adopting second laser beam

A technology of 3D printing and metal parts, applied in the direction of metal material coating process, coating, etc., can solve problems such as gaps and non-functional devices, and achieve the effects of uniform distribution, thorough remelting, and improved compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for improving the densification of 3D printed metal parts using a second laser beam, comprising:

[0025] a. Pre-treat the printing base and the printing base; the pre-treatment includes removing oil stains or other impurities on the surface of the base and the printing base, wherein the removal of oil can be done by heating or using an organic cleaner to remove oil, The printing base is used as the basis for layer-by-layer superimposition of printing layers. The printing layer of the first layer is printed on the printing base, and finally the metal parts are formed on the printing base.

[0026] b.Using the first laser and alloy powder to run on the printing base plate according to the preset trajectory, relying on multi-channel overlapping and layer-by-layer superposition for 3D printing, and inert gas protection for the workpiece surface and powder flow field during the printing process Generally, the thickness of each layer of printing layer is controlled ...

Embodiment 2

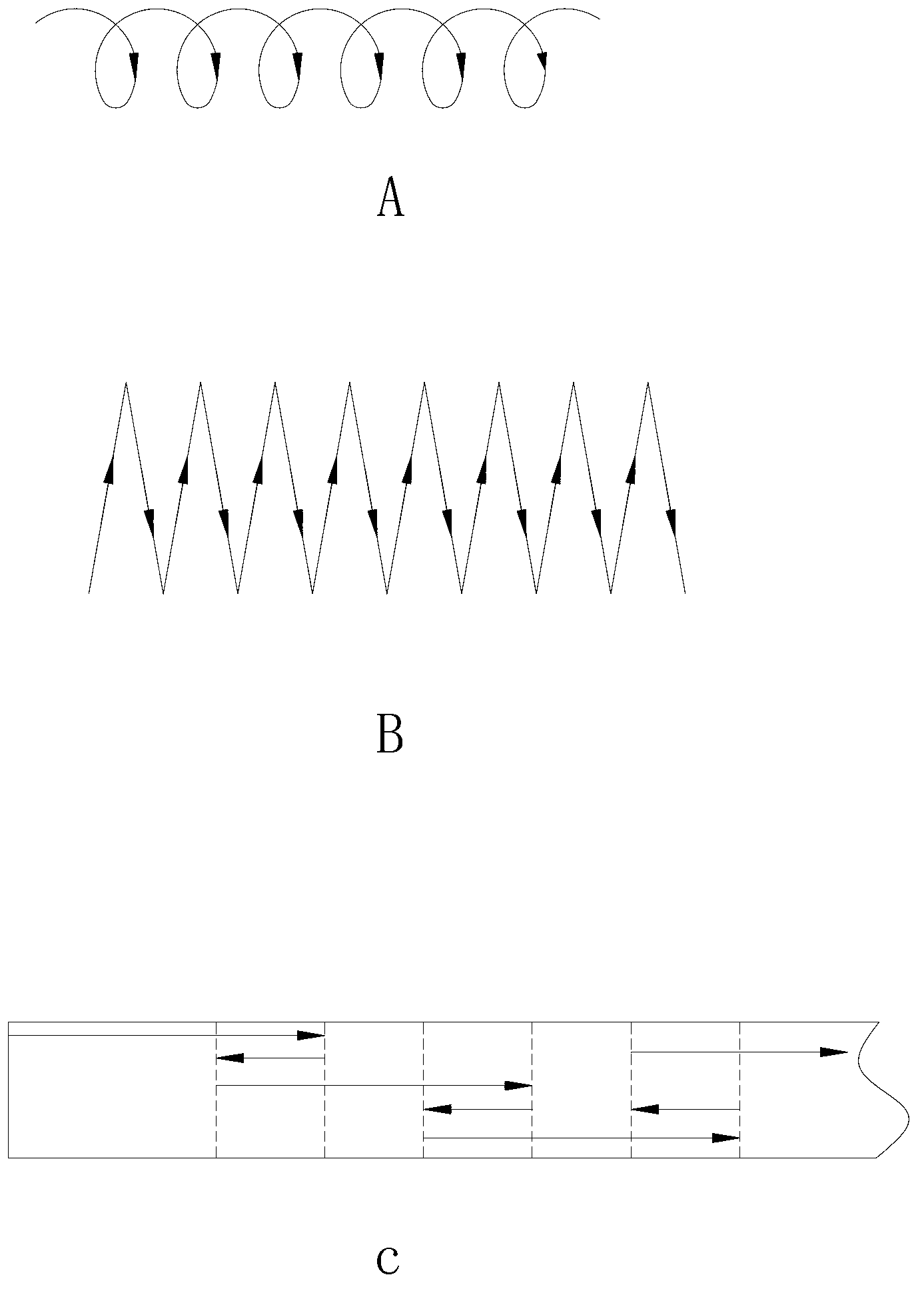

[0035] The steps in this embodiment are the same as in Embodiment 1, except that the specific process parameters are slightly different. In this embodiment, the first laser is a carbon dioxide laser, and the first laser is operated in a multi-pass overlapping mode. The alloy powder The powder feeding direction is coaxial with the first laser beam, the laser wavelength of the first laser is 10.6μm, the output power is 5000W, the running speed is 2-15mm / s, and the single-track width is 2-6mm. The second laser is also a carbon dioxide laser. Its operating speed and laser wavelength are the same as those of the first laser. The distance between the center of the spot of the second laser and the center of the spot of the first laser is 30mm. The intersecting angle between the layers is 85°, and the advancing method of the second laser is selected as a broken line, such as figure 1 As shown in Figure B, the lines in this figure schematically represent the running line of the center ...

Embodiment 3

[0041] This embodiment is basically the same as Embodiment 1, the distance between the center of the spot of the second laser and the center of the spot of the first laser is 40 mm, the angle of intersection between the second laser and the printing layer is 82°, and the stacking is also It is determined by the operation of the spot center of the second laser beam irradiated on the printing layer, such as figure 1 As shown in Figure C in Figure C, the direction of the arrow in Figure C schematically represents the running route of the center of the second laser spot. Its front and back directions are determined according to the forward direction of the first laser beam. The alloy powder used in this embodiment is a cobalt-based alloy powder, and its composition is by weight percentage: 25%WC, 1%C, 4%CaF2, 6%SiN4, 20%Cr, 4%B, 1%V, 3 %Si, 15%Mo, 1.5%Mn, the balance is Co, and the above materials are all 100-200 mesh powder.

[0042] It can be seen from the above that this meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com