Automatic wire-stripping tin plating machine

An automatic wire stripping and tin machine technology, which is applied to circuit/collector parts, electrical components, circuits, etc., and can solve the problems of large waste, low efficiency, and uneven tin application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

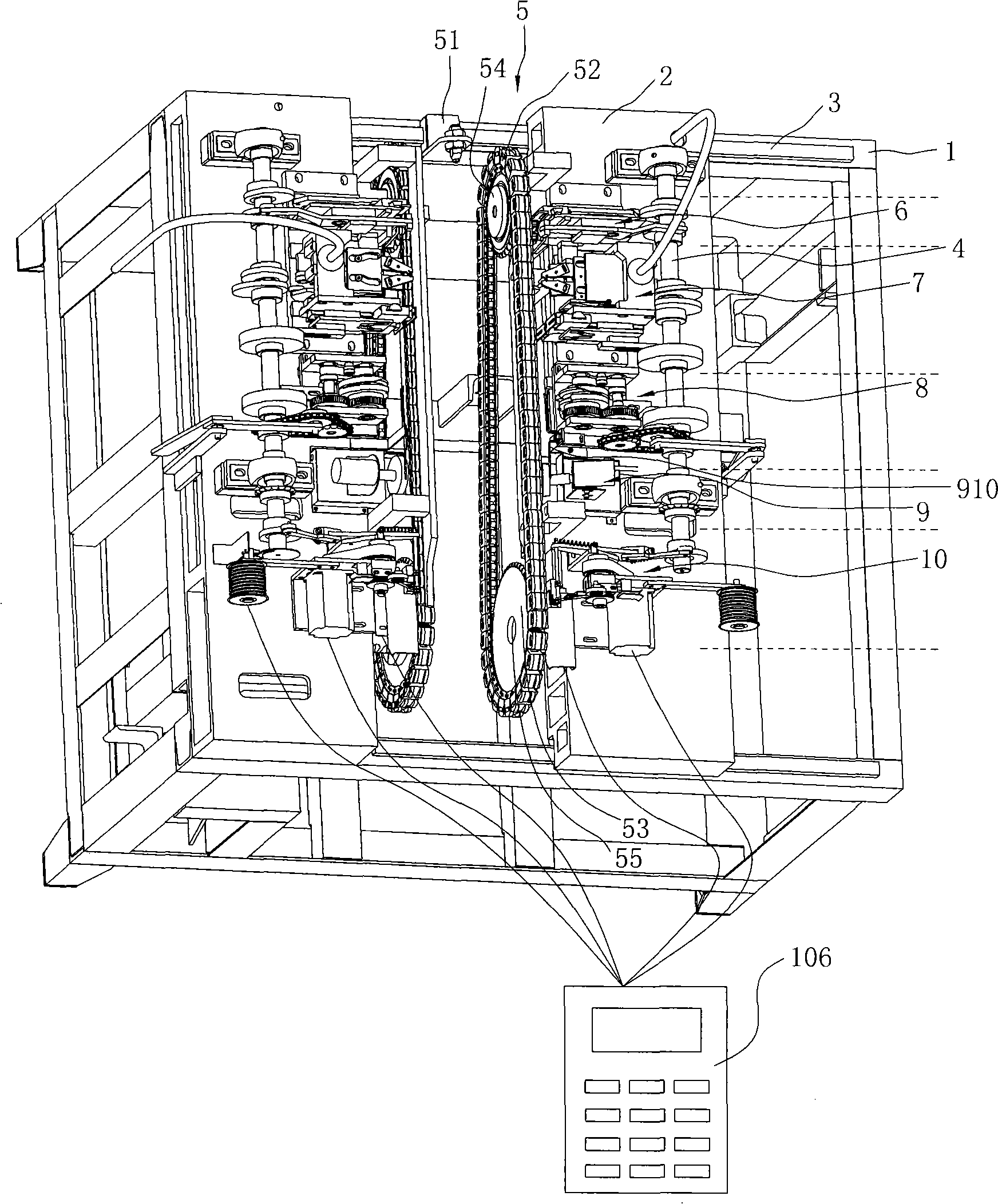

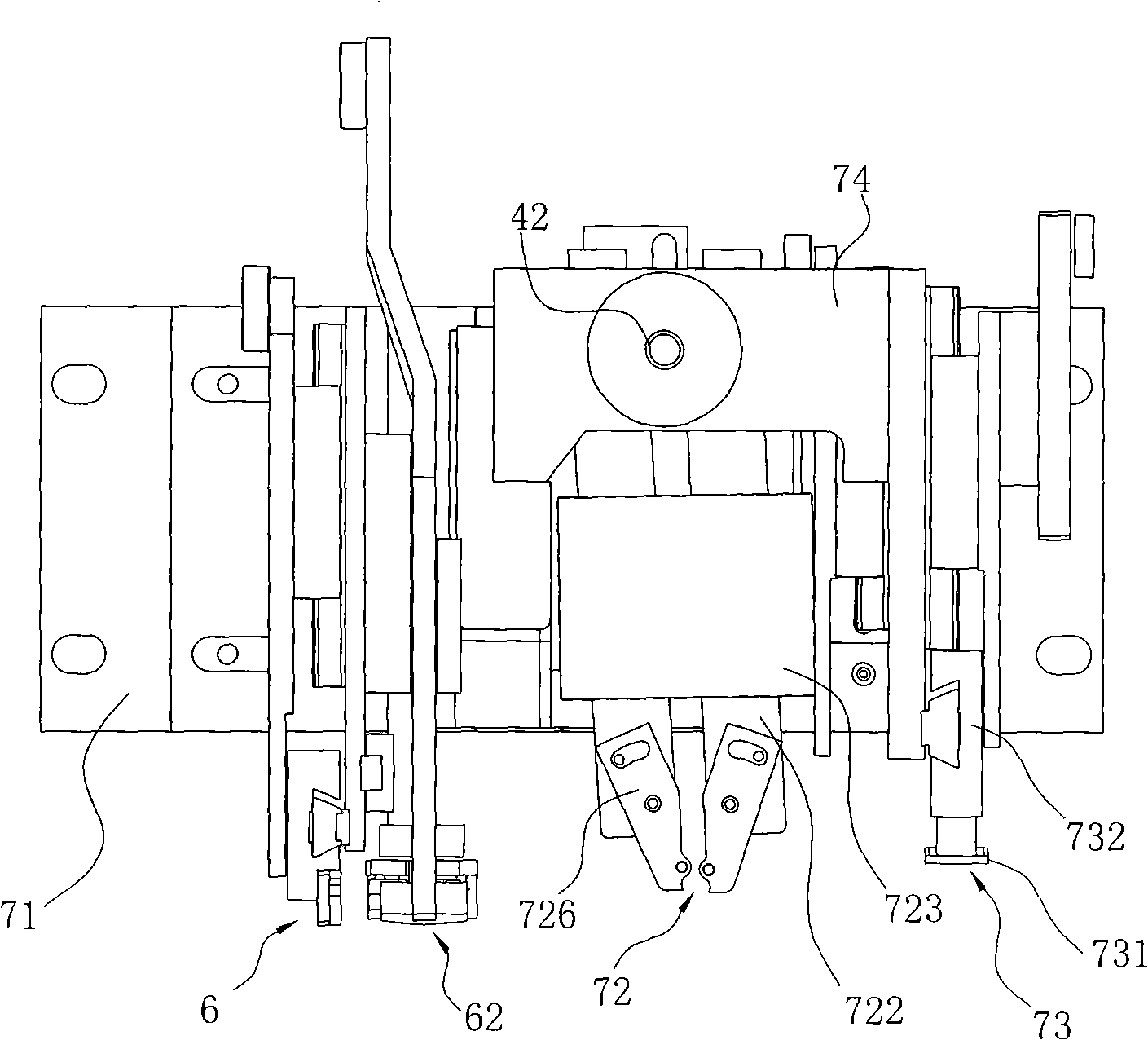

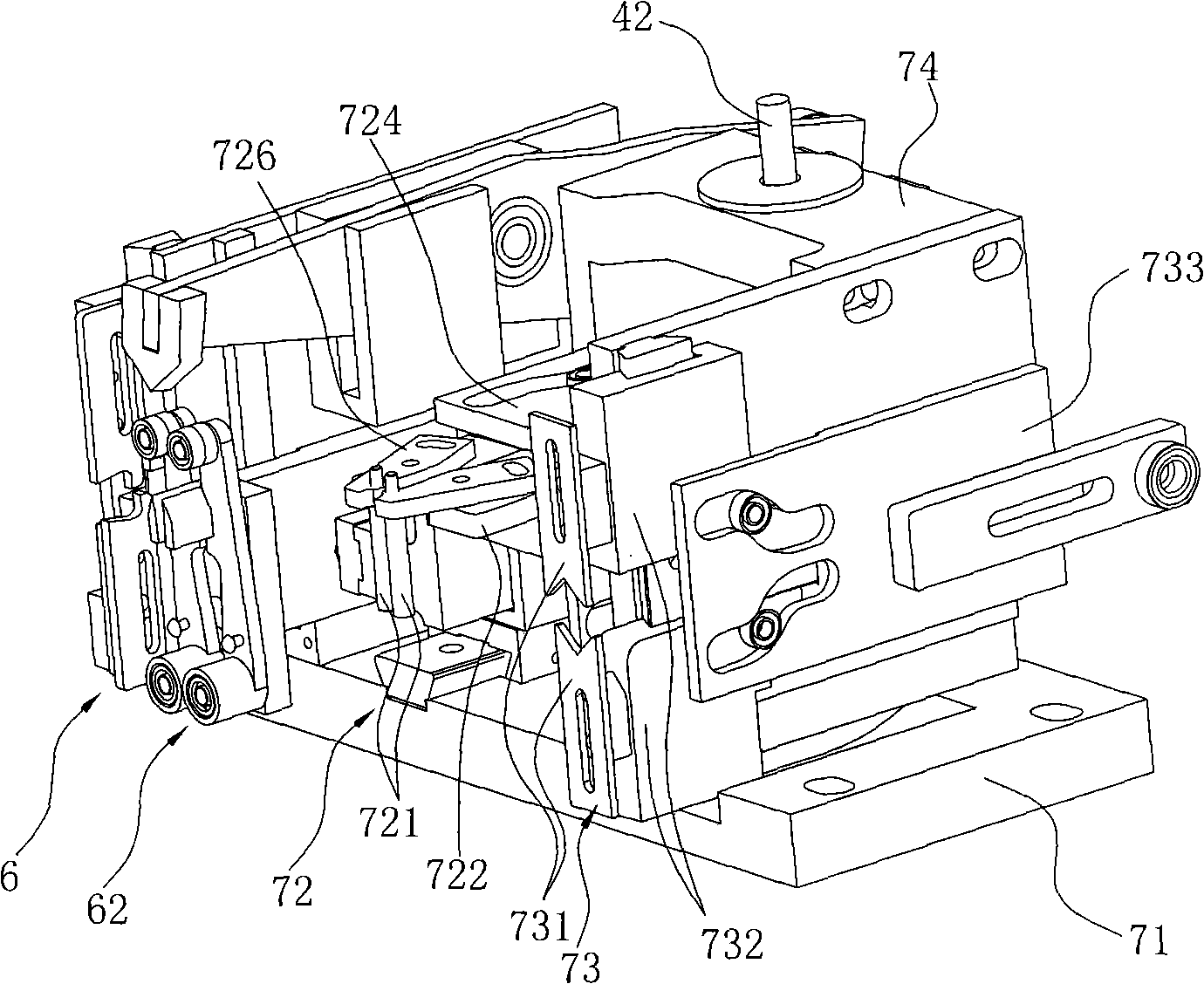

[0059] Such as figure 1 As shown, the automatic tin stripping machine includes a frame 1, a power transmission device installed on the frame 1, a wire transmission device 5, and two workbenches 2 are arranged on the top of the frame 1, and one of the workbenches 2 is fixed On the frame 1, another workbench 2 is erected on a set of parallel adjustment guide rails 3 of the frame 1, and a distance adjustment mechanism is provided between the two workbenches 2, which can move left and right along the adjustment guide rails 3. Table, adjust the distance between it and the fixed worktable to meet the needs of processing wire segments of different lengths. The wire feeding device 5 includes a wire feeding device 51 arranged on the adjusting guide rail 3 and a group of wire feeding chains 52 which are symmetrically arranged between the two workbenches and formed by a plurality of unit nodes. On the adjustment guide rail 3 between the tables 2, two worktables are symmetrically equipp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com