Cold and hot water positive and negative water vapor interaction pulse washing and drying device and method

A technology of pulse cleaning and drying device, which is applied in the directions of drying gas arrangement, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of lack of self-circulation and reversing direction functions, large water consumption, unfavorable pipelines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

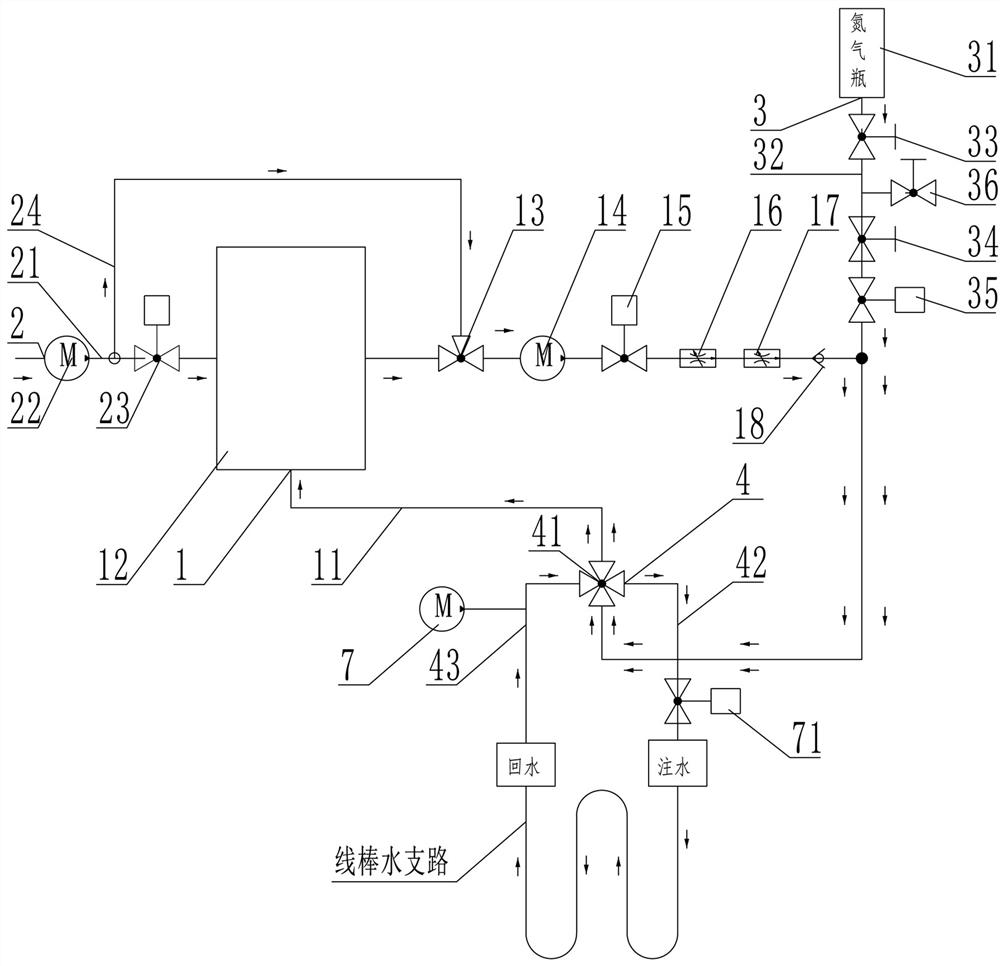

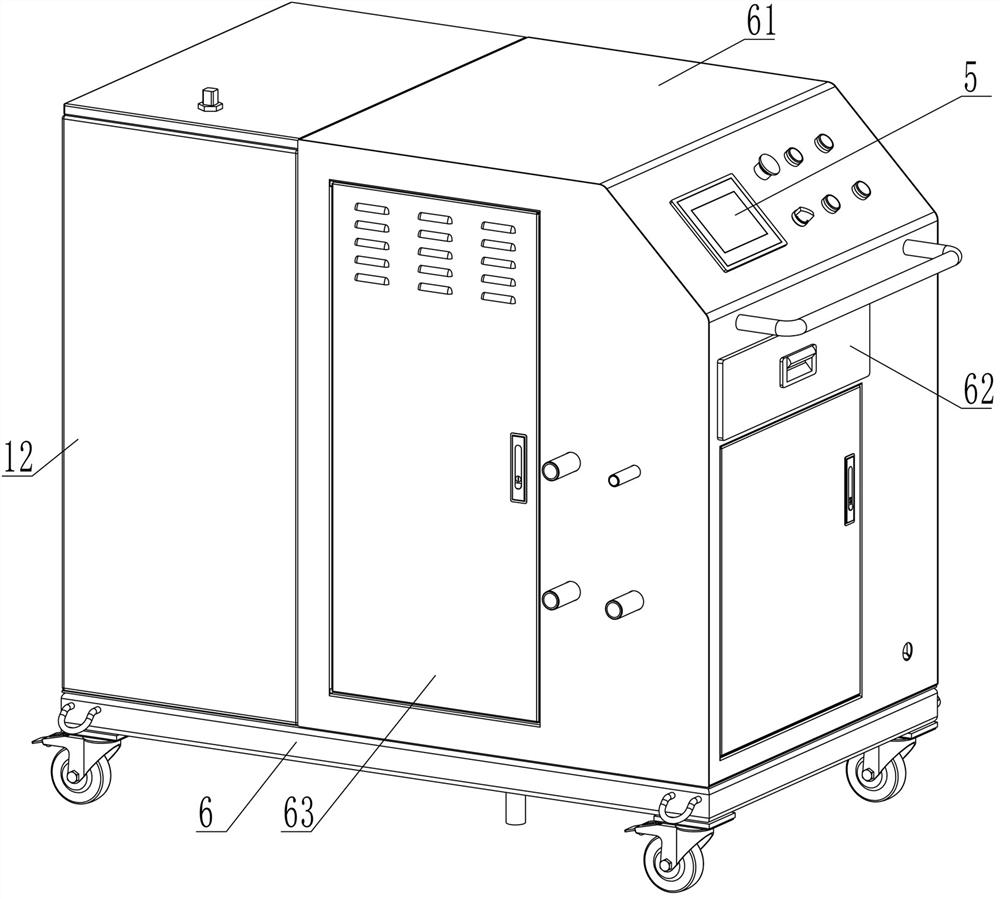

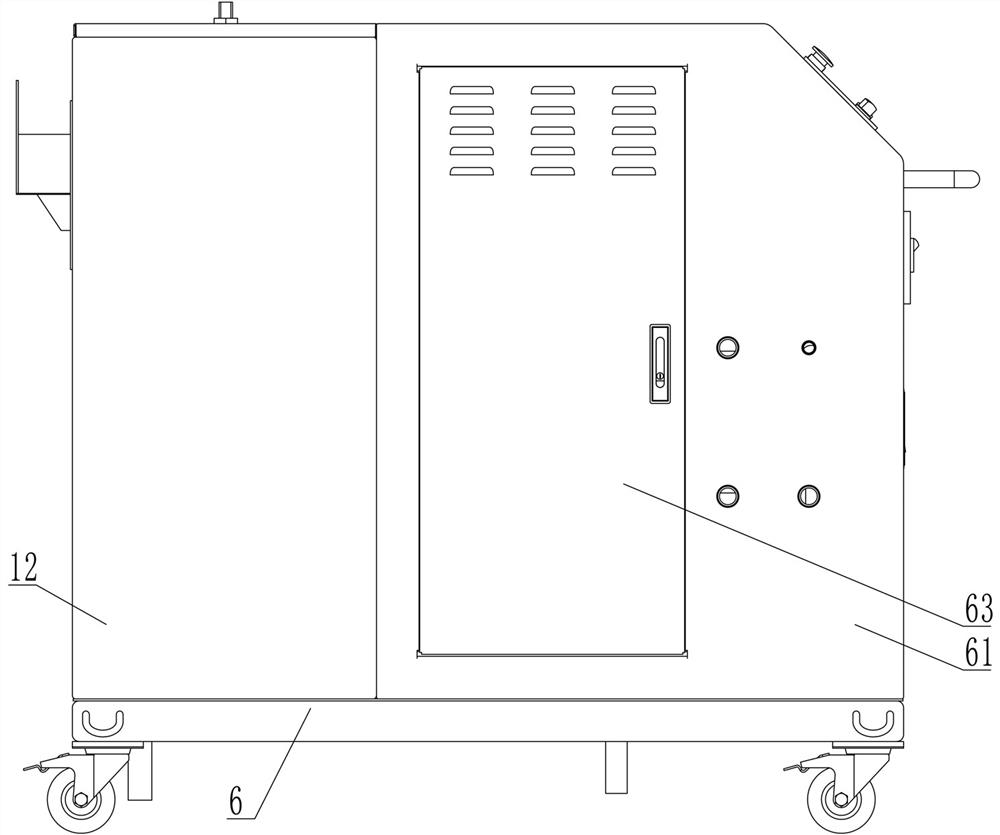

[0054] Such as Figure 1~Figure 4 Among them, a cold and hot water positive and negative water-gas alternating pulse cleaning and drying device, which includes a water circulation system 1, a water replenishment device 2, an air supply device 3, a wire rod cleaning circuit 4 and a PLC control system 5; the water replenishment device 2 and the water cycle The water tank 12 of the system 1 is connected, the air supply device 3 is connected to the water circulation pipeline 11 of the water circulation system 1, the three-position four-way reversing electric valve 41 of the wire rod cleaning circuit 4 is located in the water circulation system 1 and connected to it, the vacuum device 7 is connected to the line The rod cleaning circuit 4 is connected; the three-way electric ball valve 13 in the water circulation system 1, the centrifugal pump 14, the water circulation solenoid valve 15, the overspeed protection valve 16 and the overpressure protection valve 17, and the air supply so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com