Cooling arrangement for a humanoid robot

a technology for humanoids and cooling arrangements, which is applied in the field of cooling arrangements for humanoids, can solve the problems of significant pressure drop of air flow, insufficient natural ventilation to control the inner temperature of robots, and less effective cooling of the central back part of inner components, so as to achieve effective and uniform cooling, reduce power consumption and reduce noise. the effect of emitted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

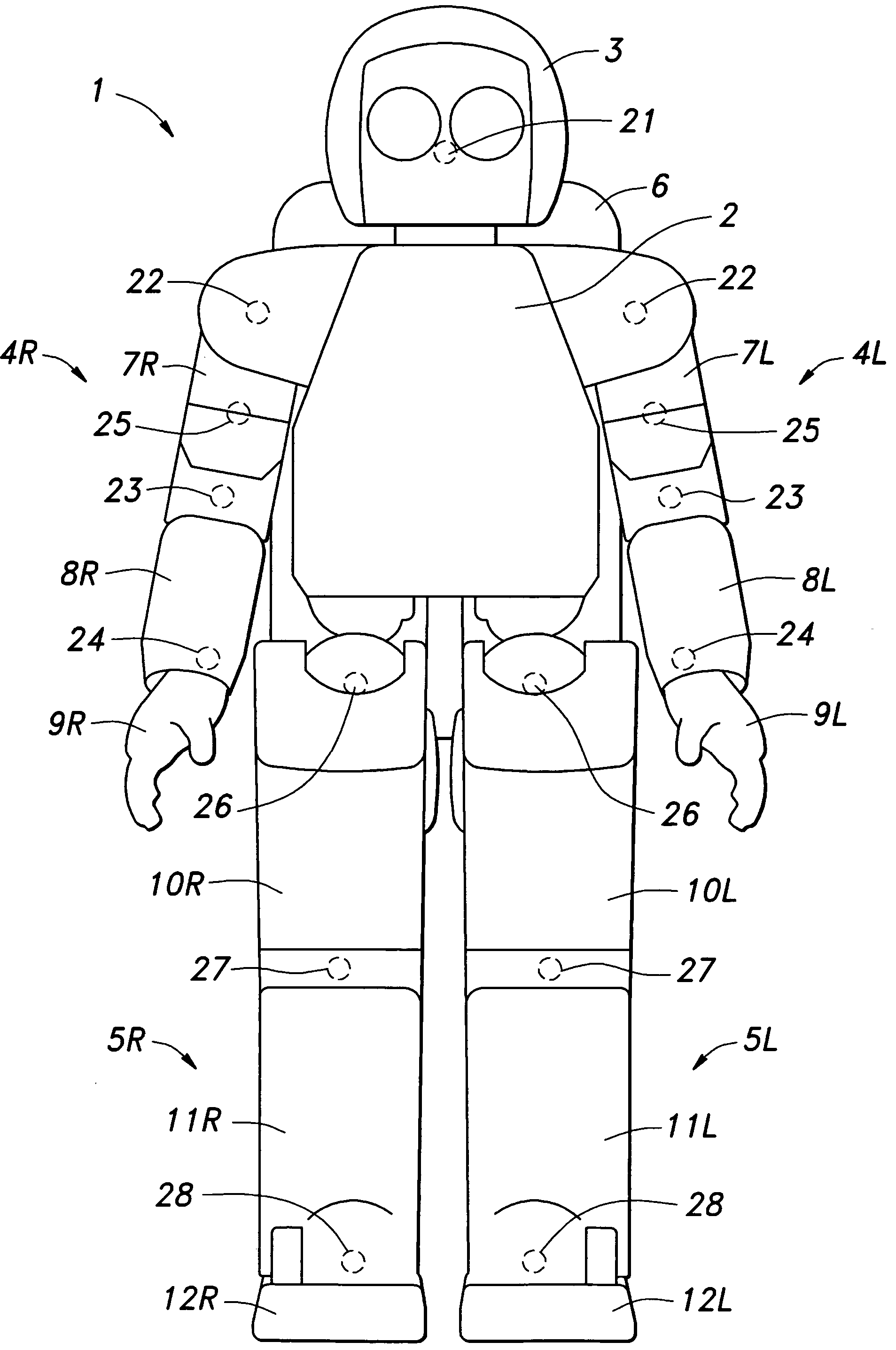

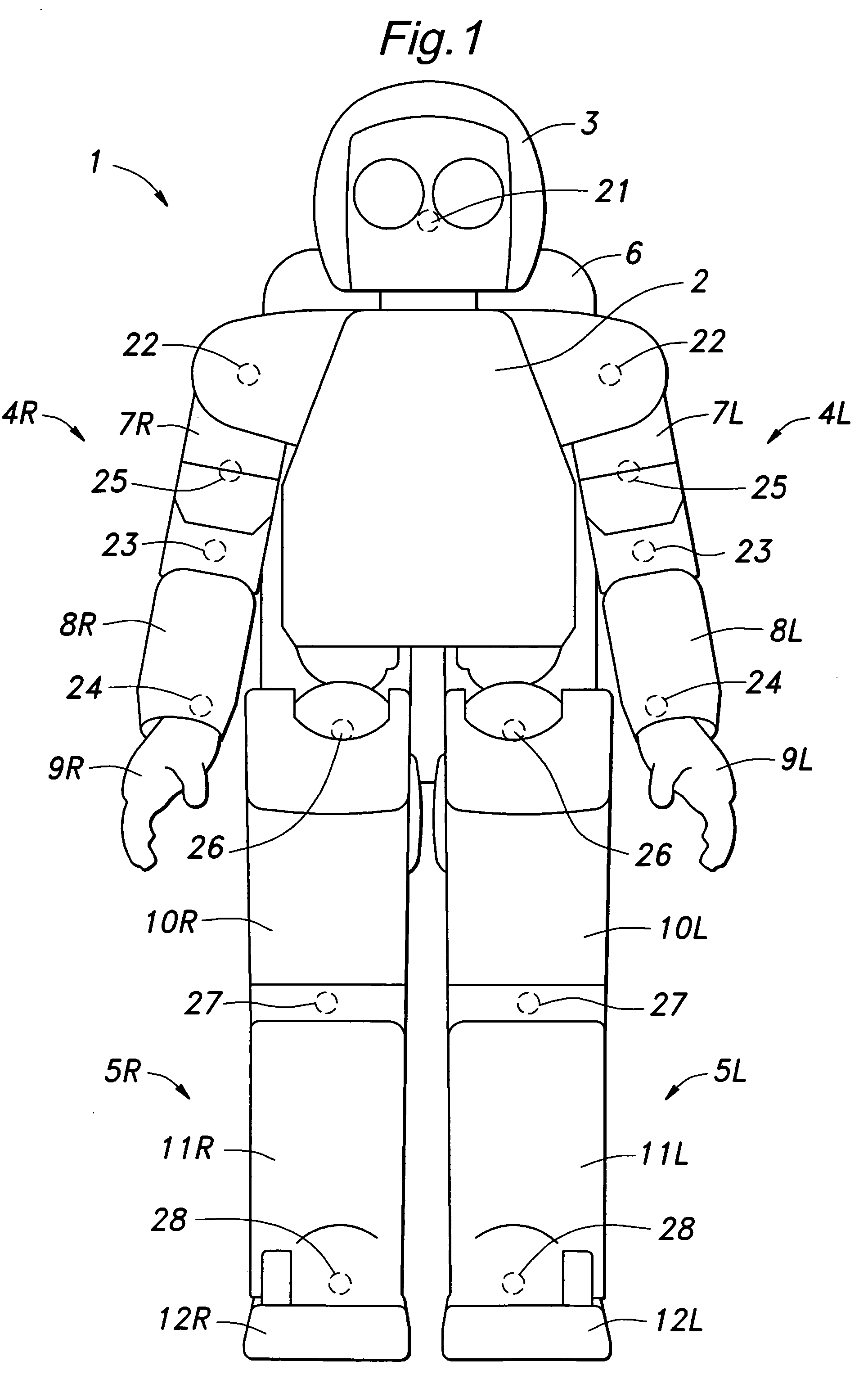

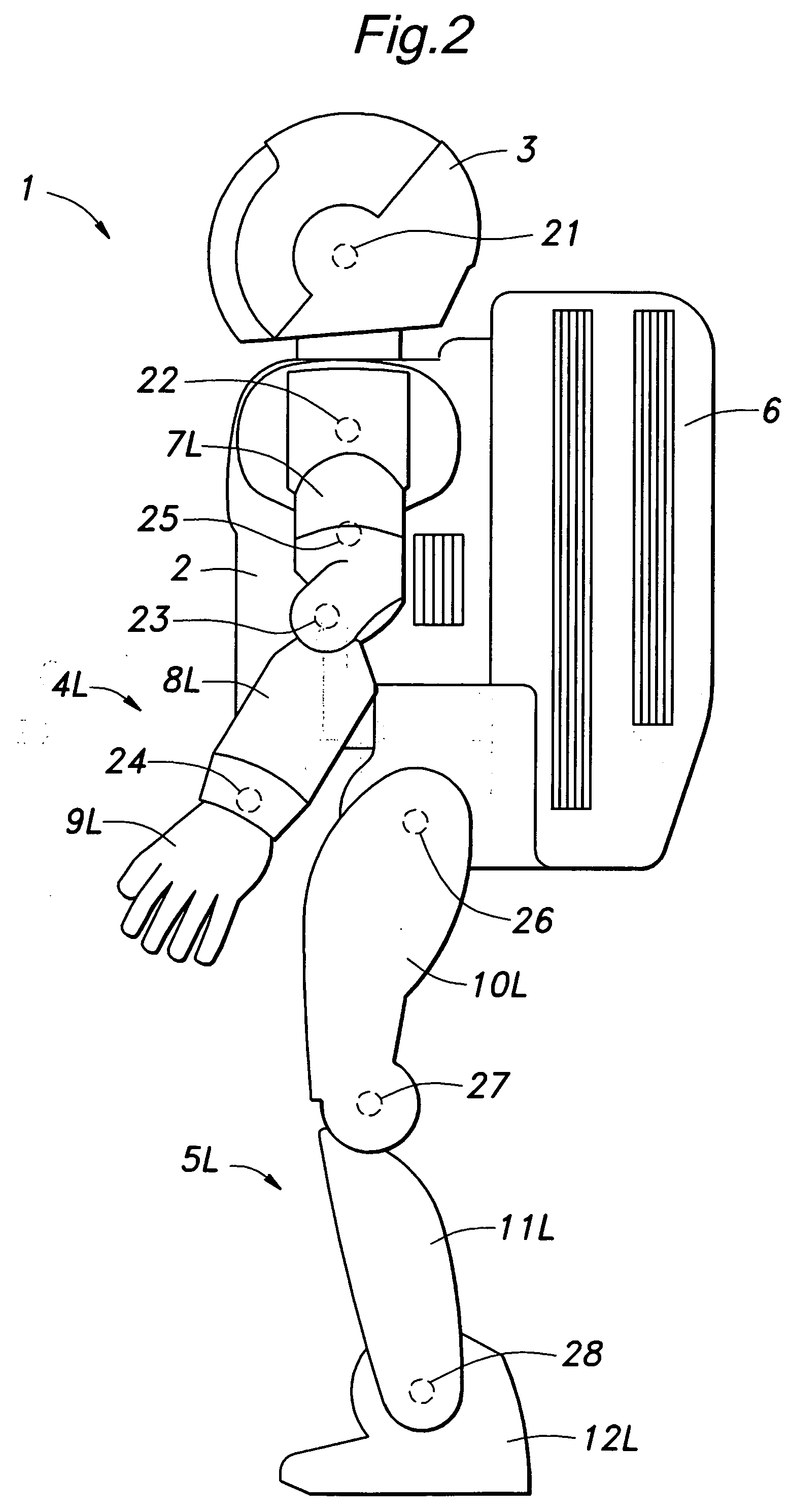

[0020] Referring to FIGS. 1 and 2;, the humanoid robot 1 (which is referred to simply as a robot hereinafter) embodying the present invention comprises a torso 2, a head 3, a pair of arms 4L and 4R, a pair of legs 5L and 5R and a backpack box 6. Each arm 4L (4R) includes an upper arm 7L (7R), a lower arm 8L (8R) and a hand 9L (9R). Likewise, each leg includes an upper leg 10L (10R), a lower leg 11L (11R) and a foot 12L (12R).

[0021] The head 3 is connected to the torso 2 via a neck joint 21. Each upper arm 7L (7R) is connected to the torso 2 via a shoulder joint 22 at an upper end thereof and connected to the corresponding lower arm 8L (8R) via an elbow joint 23 at a lower end thereof. The lower arm 8L (8R) is in turn connected to the corresponding hand 9L (9R) via a wrist joint 24. A middle part of each upper arm 7L (7R) is provided with an upper arm joint 25 so that the upper and lower parts of the upper arm can be rotated relative to each other around an axial line extending cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com