Vacuum freeze drying method and vacuum freeze dryer

A vacuum freeze-drying and drying technology, applied in the direction of drying solid materials, drying solid materials without heating, drying, etc., can solve the problems of poor freezing efficiency and poor grain quality, and achieve improved quality, uniform cooling and heating, The effect of shortening the process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

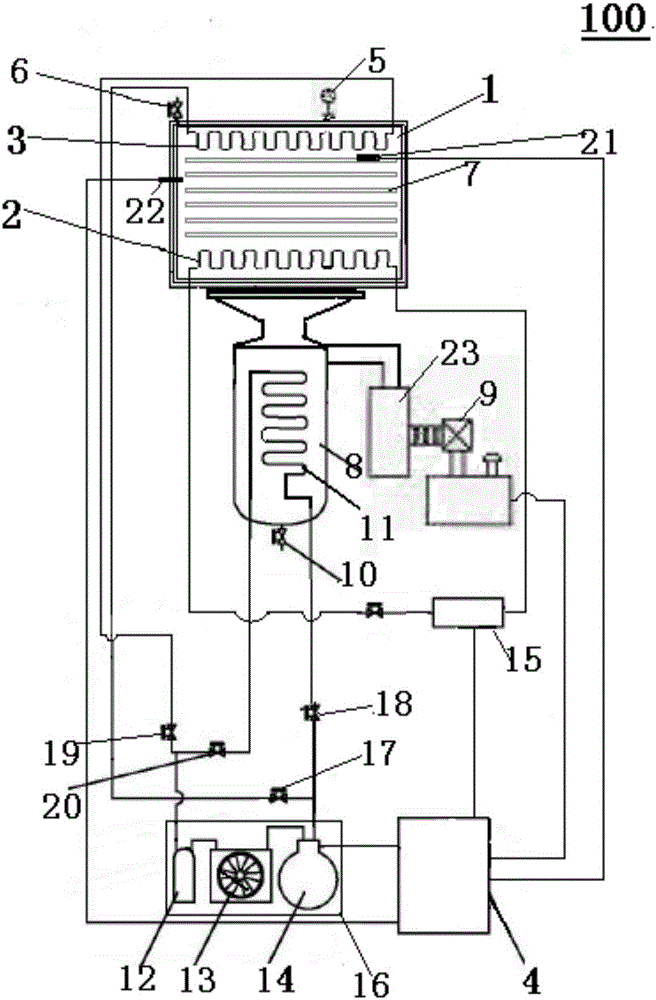

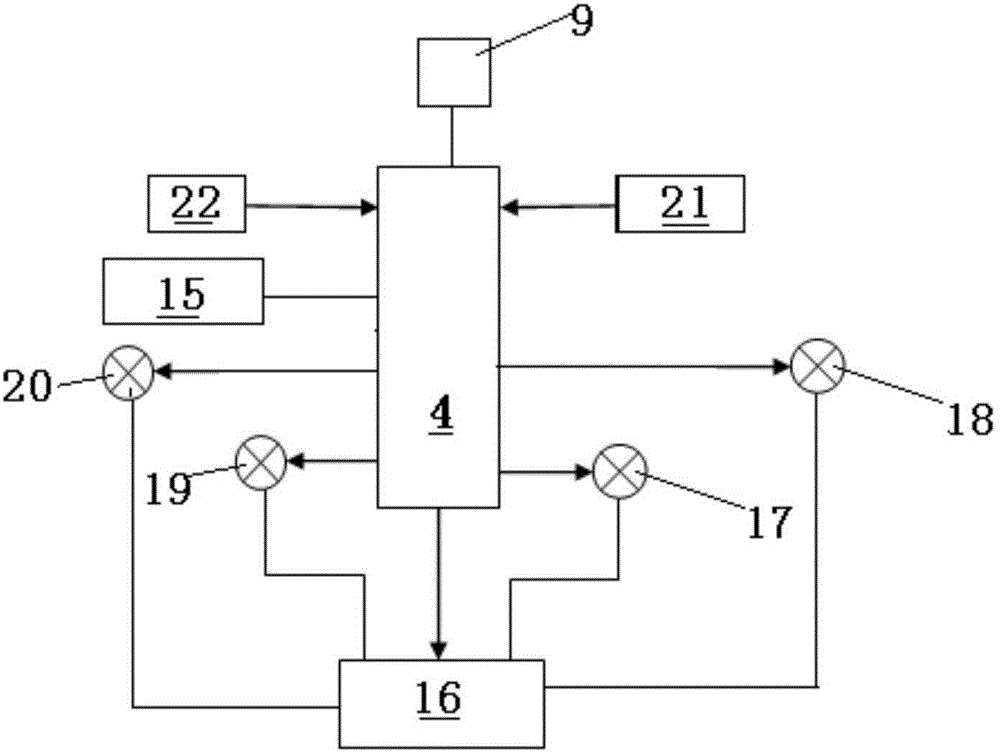

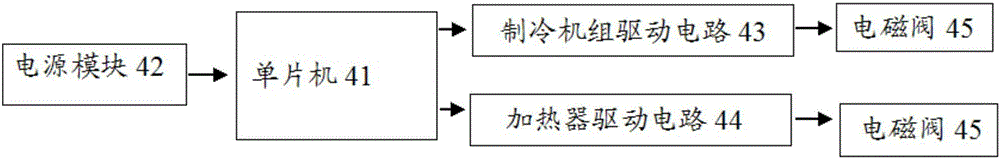

[0031] The structure and working principle of the present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments:

[0032] The invention provides a vacuum freeze-drying method for freeze-drying materials, which comprises the following steps:

[0033] a. Pre-freezing step, pre-freeze the material to 1-10°C above the eutectic point temperature of the material, so that the material can pass through the eutectic point in the shortest possible time, so as to effectively control the particle size of the crystallization crystals, thereby obtaining fine frozen Dry powder, improve the quality of freeze-dried powder products.

[0034] b. In the first heat preservation step, make the material 1-10°C above the eutectic temperature of the material, and keep it for 10-20 minutes;

[0035] c. In the quick freezing step, the temperature of the material is reduced to between -30°C and -45°C within 5-10 minutes;

[0036] d. In the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com