Cooling device provided with annular water channel and based on 3D printing technology

A 3D printing and cooling device technology, applied in the field of cooling structure, to achieve uniform cooling effect, improve economic benefits, and high cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

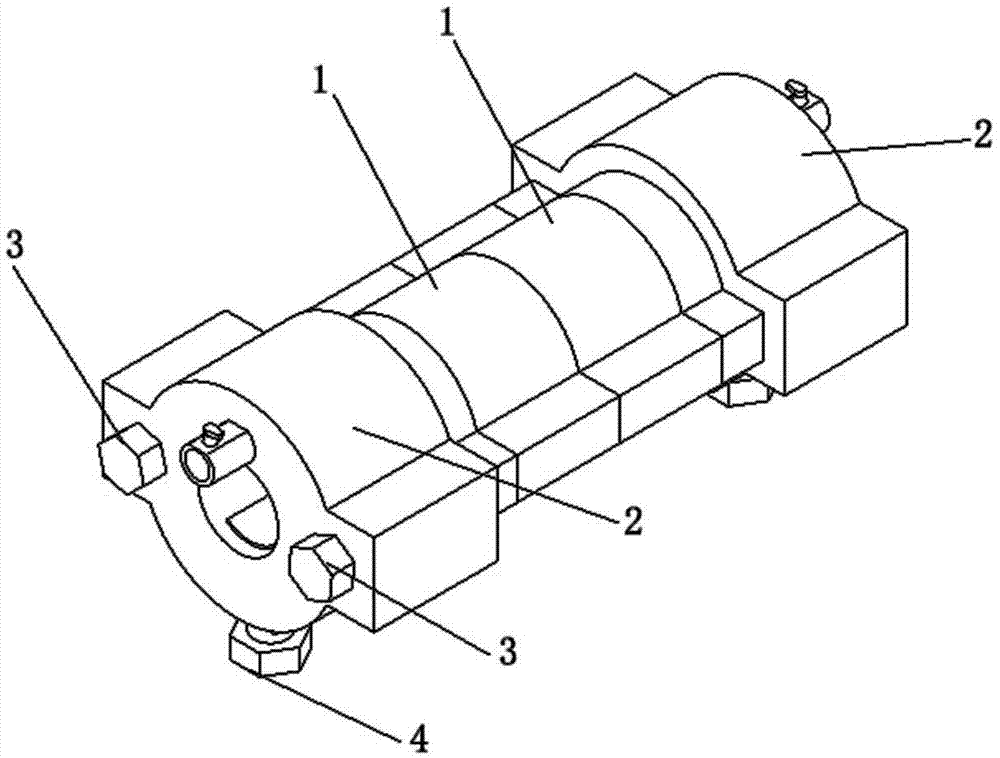

[0026] like figure 1 As shown, the embodiment of the present invention provides a cooling device with an annular waterway based on 3D printing technology, including two end fixing modules 2 and a plurality of conformal cooling modules 1 arranged between the two end fixing modules 2 .

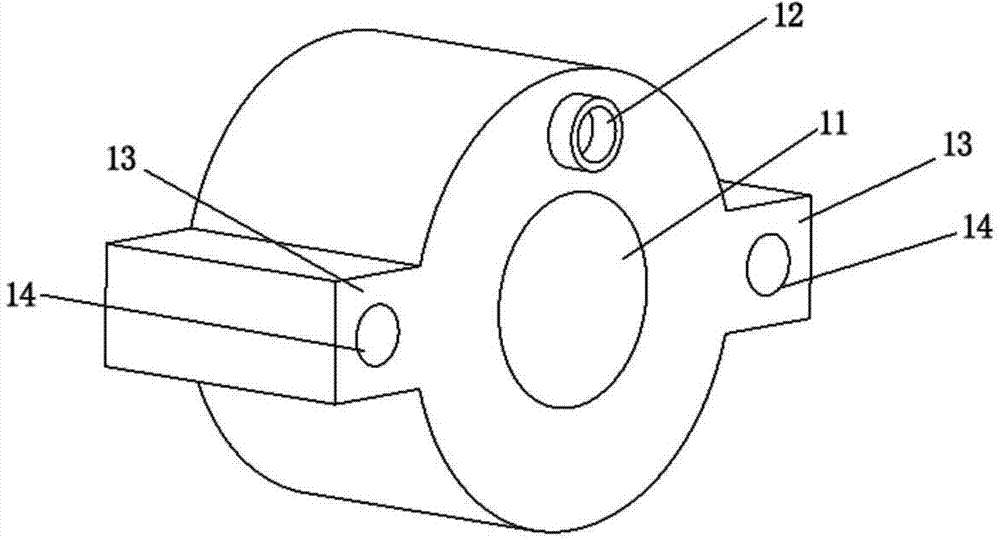

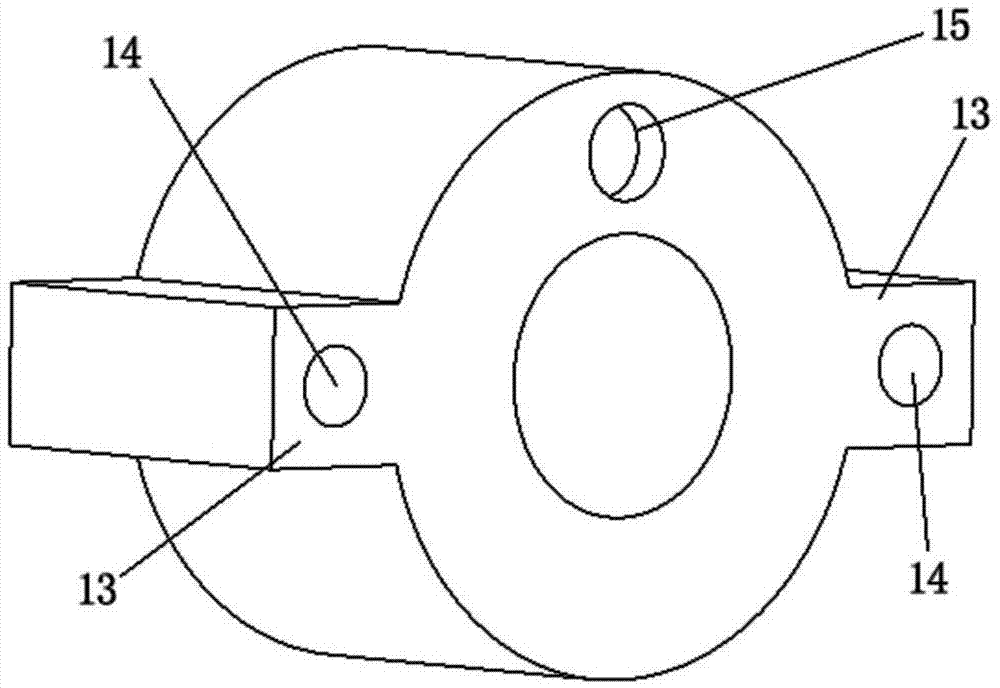

[0027] In the embodiment of the present invention, there are four conformal cooling modules 1 , and each conformal cooling module 1 has the same structure. In practical engineering applications, the structures of multiple conformal cooling modules 1 may be different. Specifically, such as figure 2 , image 3 and Figure 4 As shown, the conformal cooling module 1 is a hollow tubular member, and the inner wall of the conformal cooling module 1 forms a tubular cooling cavity 11 for placing parts to be cooled. In the embodiment of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com