Metal mold low-pressure casting mold cooling device and preparation method thereof

A low-pressure casting and mold cooling technology, applied in the field of casting, can solve problems such as water leakage, uneven cooling, loss, etc., and achieve the effects of improving yield and production efficiency, shortening casting production cycle, and reducing the possibility of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

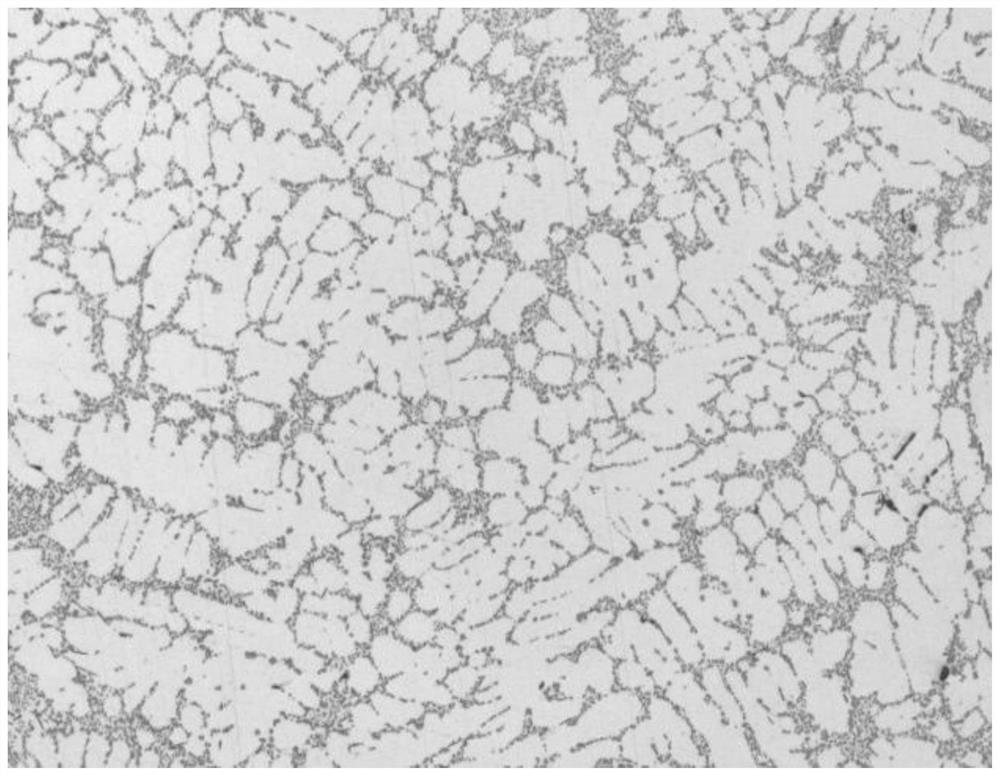

Embodiment 1

[0030] The mold of this embodiment is used to prepare a 22.5-inch wheel, and the material is A356.2 alloy. The material of the main body of the mold used in this embodiment is mold steel H13, the wheel core adopts the 3D printing metal cooling device provided by the present invention to strengthen the cooling of the wheel core, and the rest of the positions adopt traditional water cooling and air cooling devices. The metal material used for 3D printing is 18Ni300 mold steel powder.

[0031] The wheel described in Example 1 is trial-manufactured by conventional low-pressure casting method, and the specific usage method is as follows:

[0032] 1) Pre-treatment: A356.2 aluminum ingots are melted, refined and modified, degassed, and slag-treated. The composition of the molten aluminum meets the range in Table 1, and the density is ≥ 2.61g / cm 3 ; After the mold is sandblasted and sprayed with paint, it is heated to 350-380°C and then put on the machine.

[0033] Table 1 A356.2 ma...

Embodiment 2

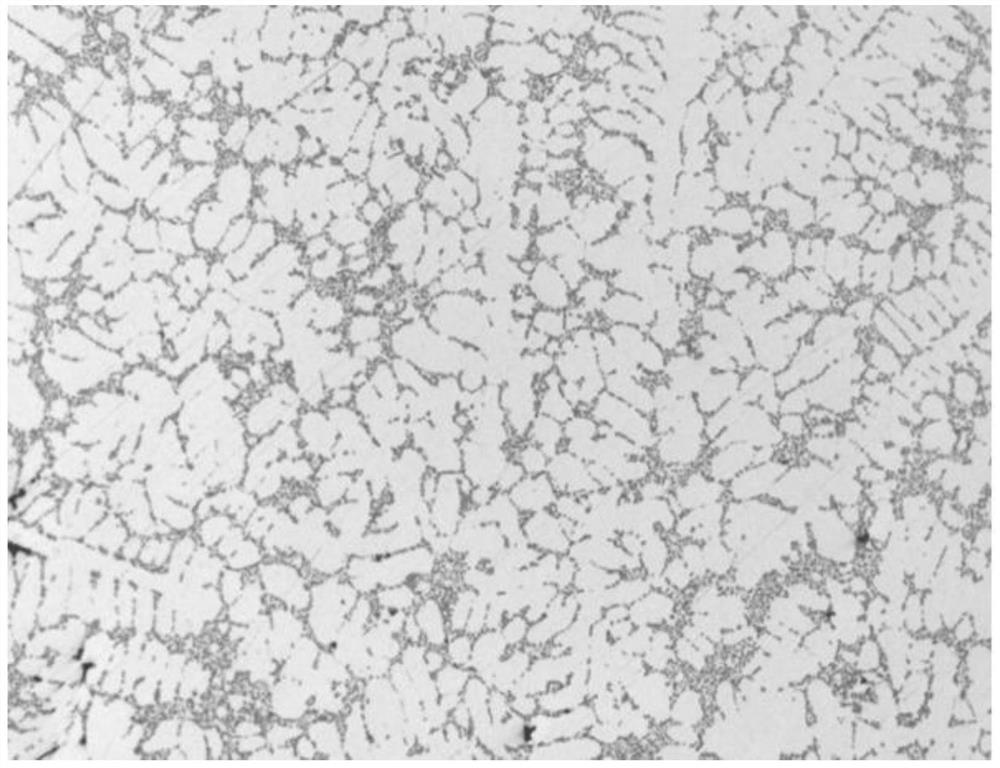

[0052] The mold of this embodiment is used to prepare a 20-inch wheel, and the material is A356.2 alloy. The material of the main body of the mold used in this embodiment is mold steel H13, the wheel core adopts the 3D printing metal cooling device provided by the present invention to strengthen the cooling of the wheel core, and the rest of the positions adopt traditional water cooling and air cooling devices. The metal material used for 3D printing is 316L stainless steel powder.

[0053] The wheel described in Example 1 is trial-manufactured by conventional low-pressure casting method, and the specific usage method is as follows:

[0054] 1) Pre-treatment: A356.2 aluminum ingots are melted, refined and modified, degassed, and slag-treated. The composition of the molten aluminum meets the range in Table 1, and the density is ≥ 2.61g / cm 3 ; After the mold is sandblasted and sprayed with paint, it is heated to 350-380°C and then put on the machine.

[0055] 2) According to t...

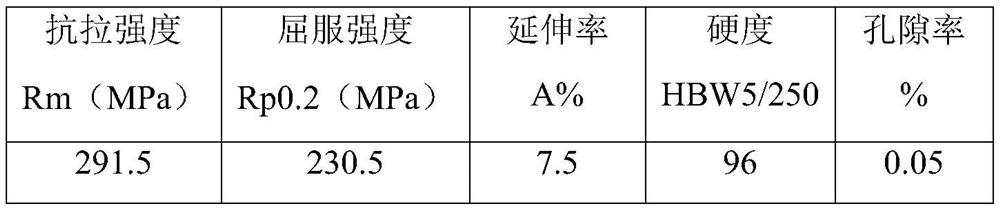

Embodiment 3

[0072] The mold of this embodiment is used to prepare a 22.5-inch wheel, and the material is A356.2 alloy. The main material of the mold used in this example is mold steel H13, the spokes and the core parts adopt the 3D printing metal cooling device provided by the present invention to strengthen the cooling of the spokes and the core parts, and the rest of the positions adopt traditional water cooling and air cooling devices . The metal material used for 3D printing is 18Ni300 mold steel powder.

[0073] The wheel described in embodiment 3 is trial-manufactured by the conventional low-pressure casting method, and the specific usage method is as follows:

[0074] 3) Pre-treatment: A356.2 aluminum ingots are melted, refined and modified, degassed, and slag-removed. The composition of the molten aluminum meets the range in Table 1, and the density is ≥ 2.61g / cm 3 ; After the mold is sandblasted and sprayed with paint, it is heated to 350-380°C and then put on the machine.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com