Die capable of shortening working time and working method of die

A mold and cooling channel technology, applied in the field of molds that shorten the working hours, can solve the problem that the mold structure cannot meet its needs, and achieve the effects of reasonable cooling, time saving, energy saving, and cooling time reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

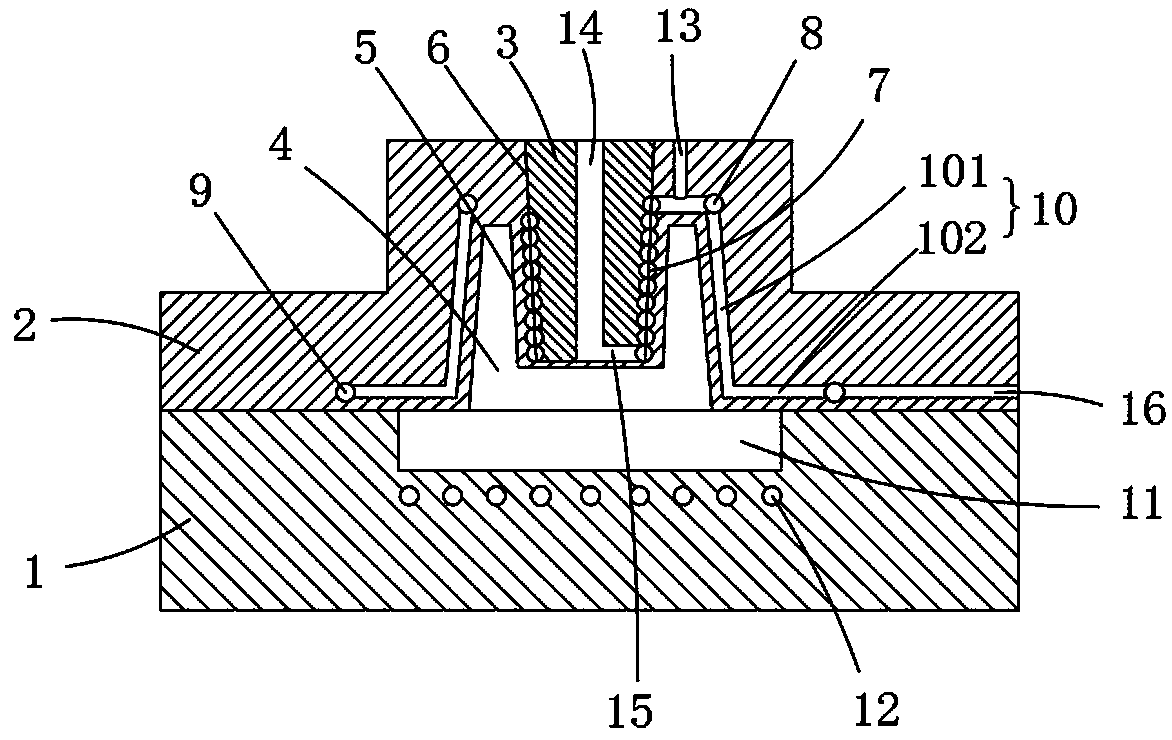

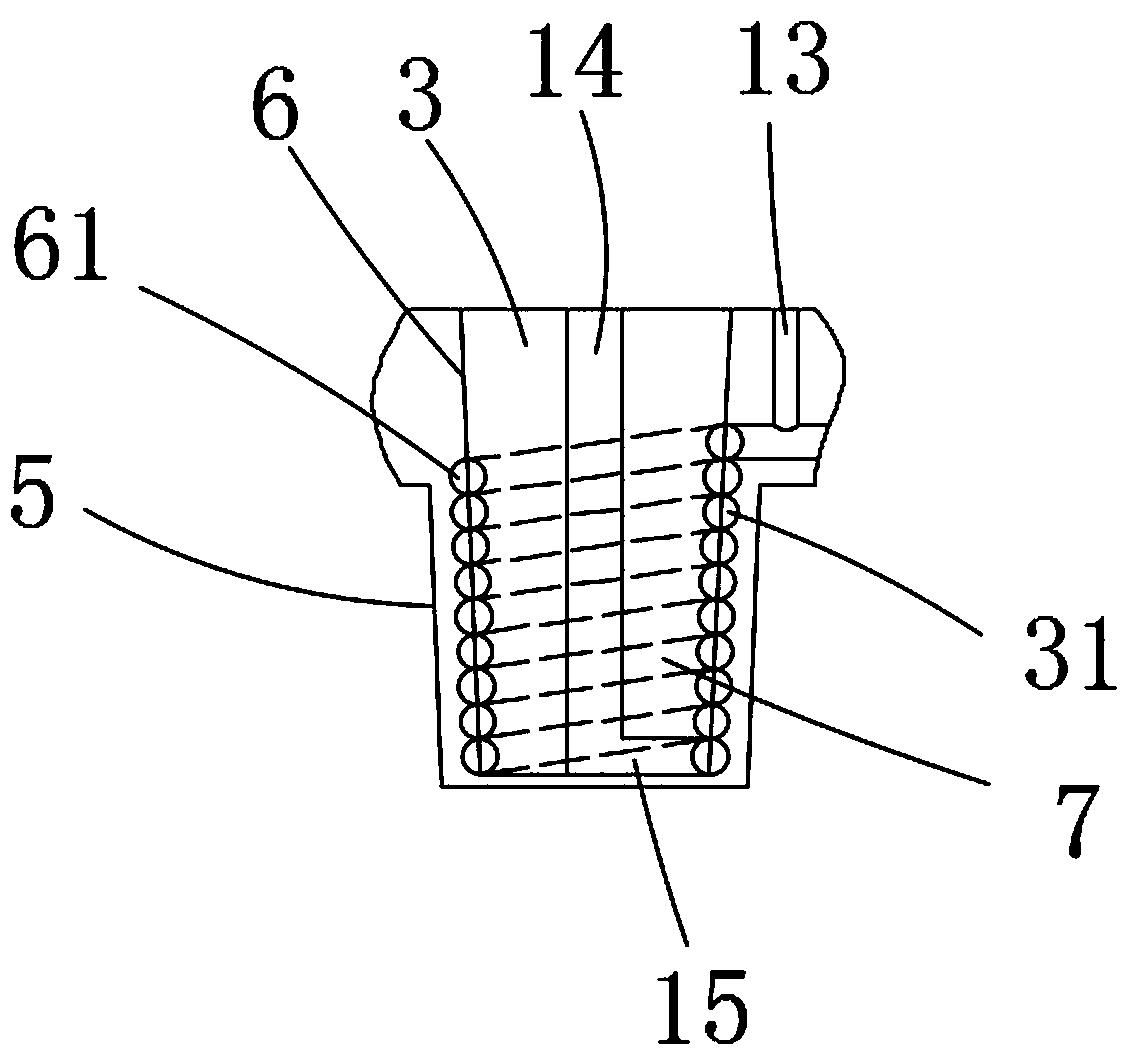

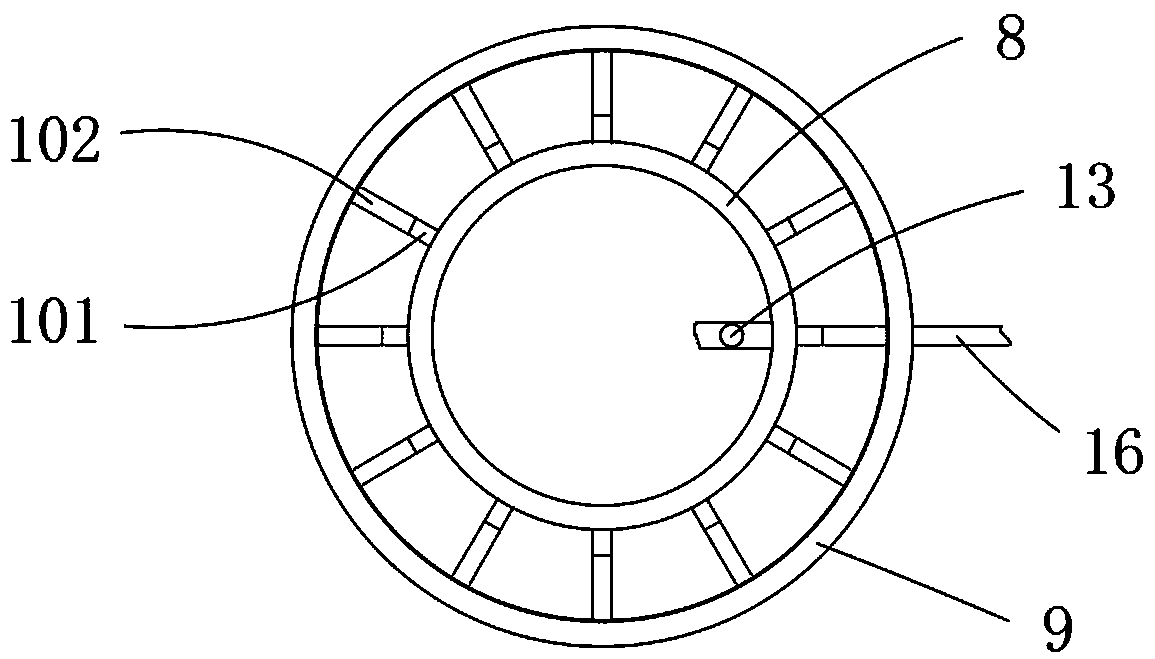

[0029] A kind of mold that shortens working hours of the present invention, as Figure 1 to Figure 4 As shown, it includes a lower mold 1, an upper mold 2, and an auxiliary cooling structure 3 arranged on the upper mold 2. The lower end of the upper mold 2 is provided with an upper cavity 4, and the bottom of the upper cavity 4 is provided with a raised portion 5. An assembly cavity 6 for installing the auxiliary cooling structure 3 is provided between the raised portion 5 and the upper end of the upper mold 2; the outer wall of the auxiliary cooling structure 3 is provided with a group of first helical depressions 31, and the assembly cavity 6 The wall is provided with a set of spiral second recesses 61, the first recess 31 and the second recess 61 butt to form a spiral first cooling channel 7; the upper end of the upper mold 2 and the upper cavity 4 An annular water inlet channel 8 is provided between them, an annular water outlet channel 9 is provided at the lower end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com