A disc brake rebound system for an electric vehicle

A kind of brake rebound, electric vehicle technology, applied in the direction of brake actuator, gear transmission mechanism, mechanical equipment, etc., can solve the trouble of brake shoe rebound performance, increase the power consumption of the rider, and the brake rebound is not sensitive enough, etc. problems, to achieve the effect of a wide range of applications, a simple structure, and a large force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

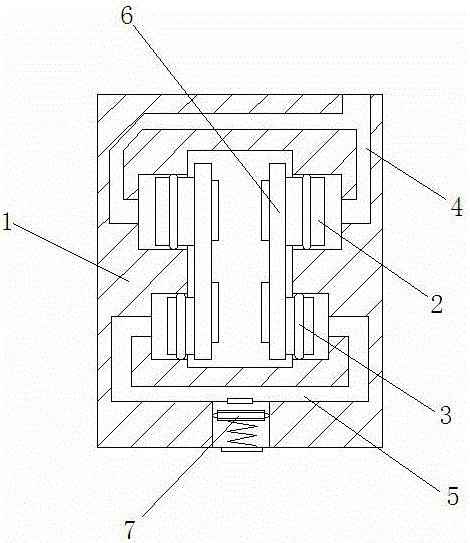

[0015] Such as figure 1 As shown, a disc brake rebound system for an electric vehicle of the present invention includes a caliper structure 1 installed on the brake disc, and a pair of oil circuit piston chambers and a pair of gas piston chambers are provided in the caliper structure 1, and a pair of An oil piston 2 is arranged in each of the oil piston chambers, and a gas piston 3 is respectively arranged in a pair of gas piston chambers. The brake disc is located between the pair of oil pistons 2 and the pair of gas pistons 3. The brake oil pipe 4 is connected to the oil piston chamber, and the gas passage 5 is connected to the pair of gas piston chambers. The oil passage piston 2 and the gas piston 3 on the same side are connected by the brake shoe 6. Pressure air groove, the spring air plug 7 that is used for sucking in and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com