Mononuclear multi-shell lithium iron manganese phosphate positive electrode material, preparation method and secondary battery

A multi-shell ferromanganese phosphate and lithium manganese iron phosphate technology, which is applied in the direction of secondary batteries, battery electrodes, chemical instruments and methods, etc., can solve the problems that the electrochemical performance of lithium manganese iron phosphate cathode materials needs to be further improved, and achieve improvement Excellent electrochemical performance, improved compaction density, and low-temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

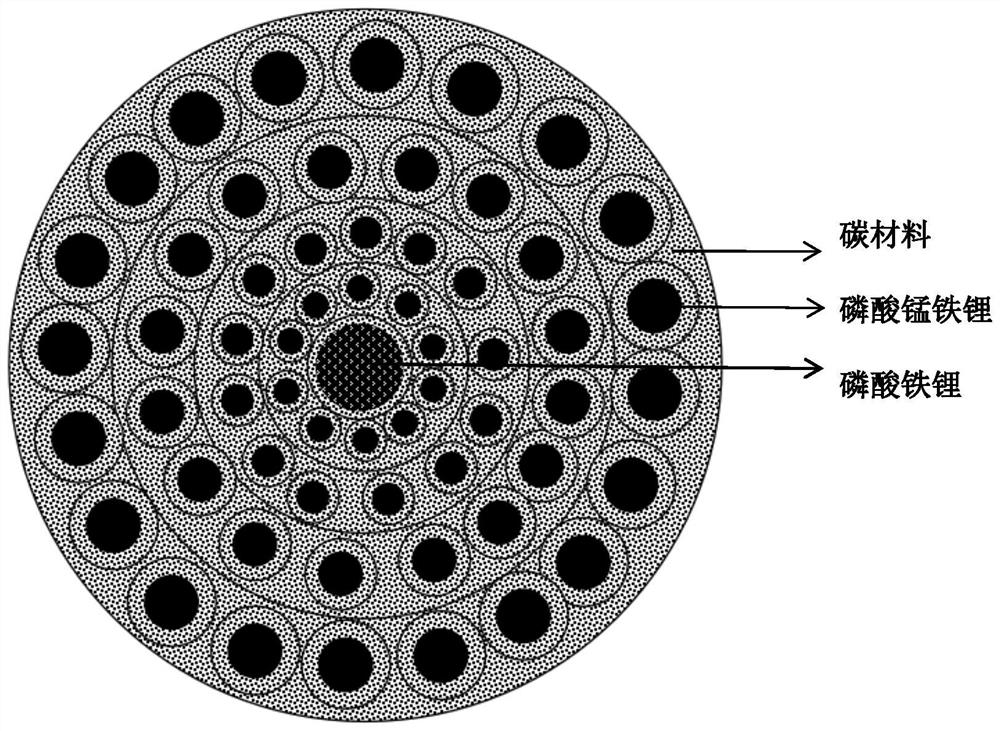

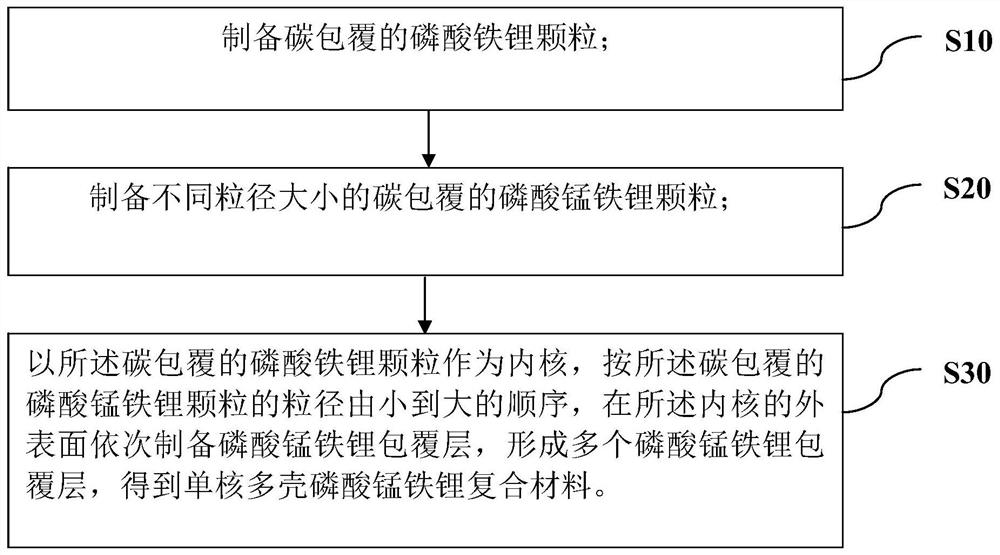

[0035] as attached figure 2 As shown, the second aspect of the embodiments of the present application provides a preparation method of a single-core multi-shell lithium manganese iron phosphate composite material, comprising the following steps:

[0036] S10. Preparation of carbon-coated lithium iron phosphate particles;

[0037] S20. Prepare carbon-coated lithium iron manganese phosphate particles of different particle sizes;

[0038] S30. Using the carbon-coated lithium iron phosphate particles as the inner core, in the order of the particle size of the carbon-coated lithium iron phosphate particles from small to large, successively preparing a lithium iron phosphate coating layer on the outer surface of the inner core to form A plurality of lithium manganese iron phosphate coating layers are obtained to obtain a single-core multi-shell lithium manganese iron phosphate composite material.

[0039] In the preparation method of the single-core multi-shell lithium iron manga...

Embodiment 1

[0069] A single-core multi-shell lithium manganese iron phosphate composite material, the preparation of which comprises the steps:

[0070] 1. Take 1 g of lithium iron phosphate LFP and pass nitrogen through a tube furnace, add 0.2 g of glucose, and bake at 750 °C for 5 hours to obtain carbon-coated lithium iron phosphate.

[0071] 2. Take 400g of lithium iron manganese phosphate LFMP and pass nitrogen through the tube furnace, add 80g of glucose and mix well, then take 4g respectively and roast at 630℃ for 5h to obtain the first carbon-coated lithium iron manganese phosphate particles; take 12g and press it at 670℃ The second carbon-coated lithium iron manganese phosphate particles were obtained by roasting for 5 hours; 84 g were roasted at 700°C for 5 hours to obtain the third carbon-coated lithium manganese iron phosphate particles; 300 g were roasted at 750 °C for 5 hours to obtain the fourth carbon-coated phosphoric acid. Lithium iron manganese particles.

[0072] 3. Af...

Embodiment 2

[0084] A single-core multi-shell lithium manganese iron phosphate composite material, the preparation of which comprises the steps:

[0085] 1. Take 1 g of lithium iron phosphate LFP and pass nitrogen through a tube furnace, add 0.2 g of glucose and bake at 800 °C for 5 hours to obtain carbon-coated lithium iron phosphate.

[0086]2. Take 500g of lithium iron manganese phosphate LFMP and pass nitrogen through the tube furnace, add 100g of glucose and mix well, then take 5g respectively and roast at 650℃ for 5h to obtain the first carbon-coated lithium iron manganese phosphate particles; take 15g and press it at 700℃ The second carbon-coated lithium iron manganese phosphate particles were obtained by roasting for 5 hours; 90 g were roasted at 730°C for 5 hours to obtain the third carbon-coated lithium manganese iron phosphate particles; 390 g were roasted at 800 °C for 5 hours to obtain the fourth carbon-coated phosphoric acid. Lithium iron manganese particles.

[0087] 3. Aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com