Plate heat tube type solar photovoltaic-photothermal composite heat collector and production process thereof

A solar photovoltaic and flat heat pipe technology, which is applied in the field of solar thermal collectors, can solve the problems of low integration of the manufacturing process, weak heat transfer capability, decreased heat transfer performance, etc., achieves efficient and feasible production process, and realizes modular production. , the effect of no water penetration and scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing, the present invention will be further described through embodiment. The same elements or components in these figures are denoted by the same reference numerals, not for limitation. For the sake of brevity and clarity in description and illustration, some devices of the present invention are not shown in the drawings, but this does not affect the understanding of the content of the present invention by relevant personnel including those of ordinary skill in the art.

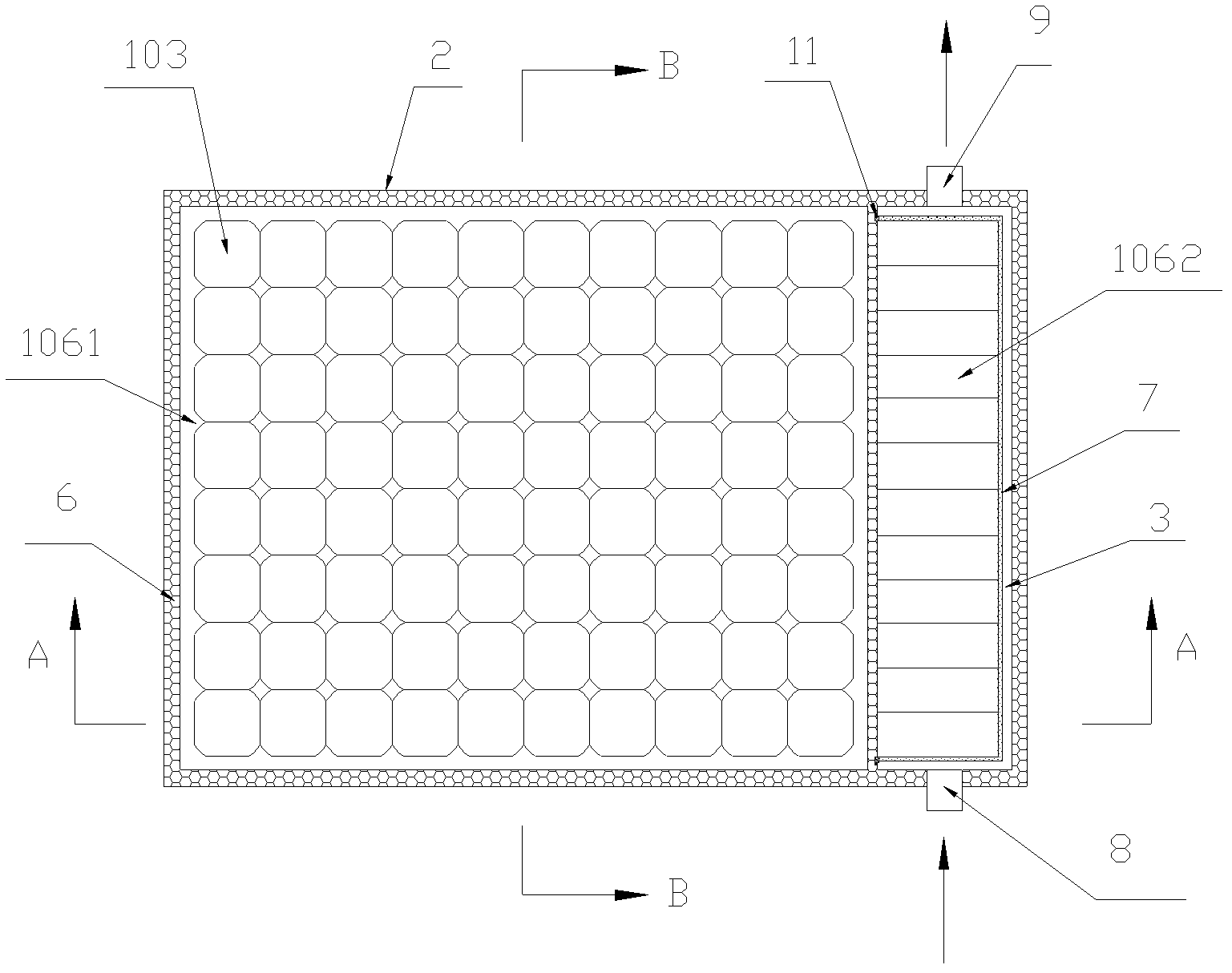

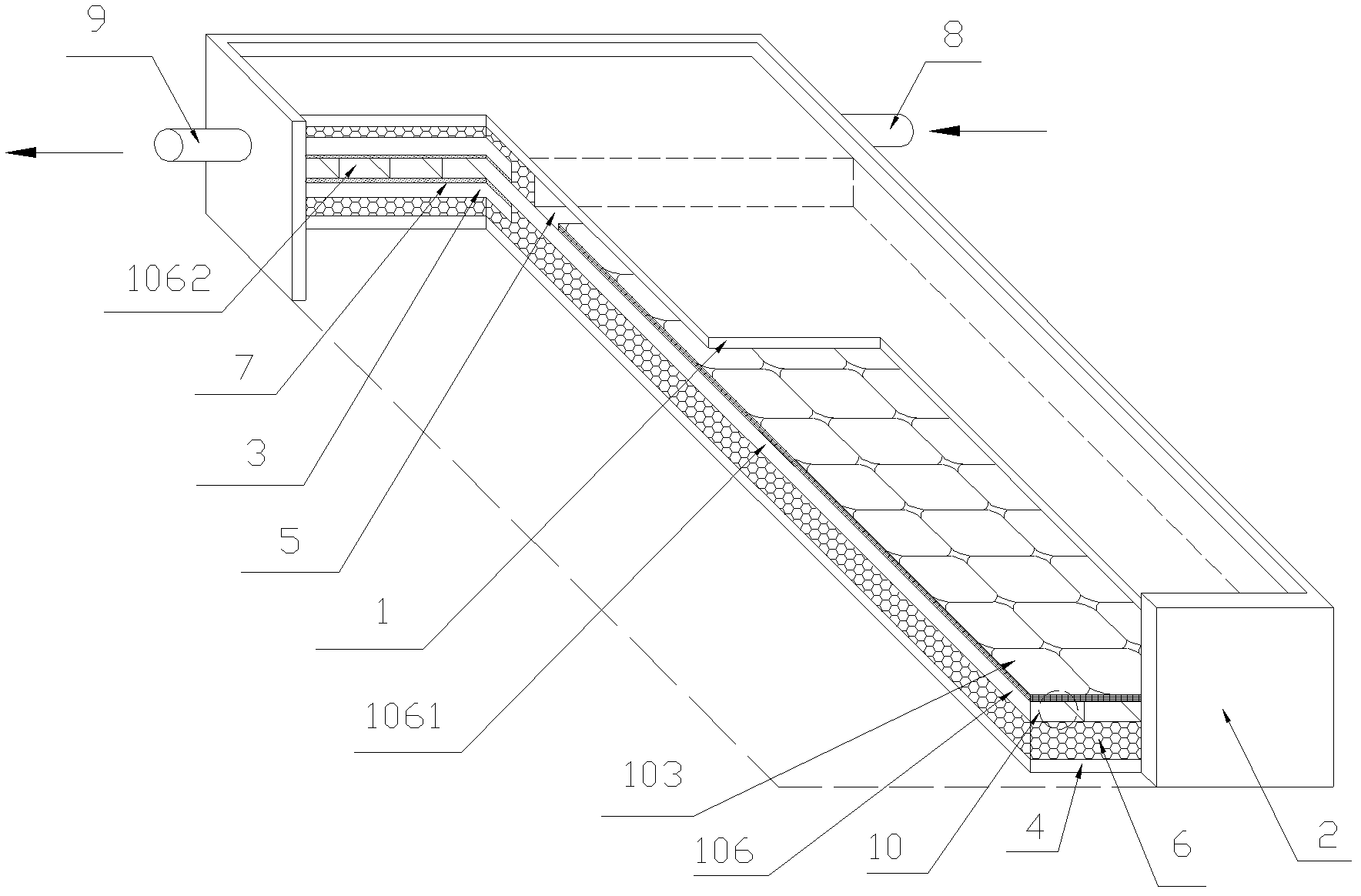

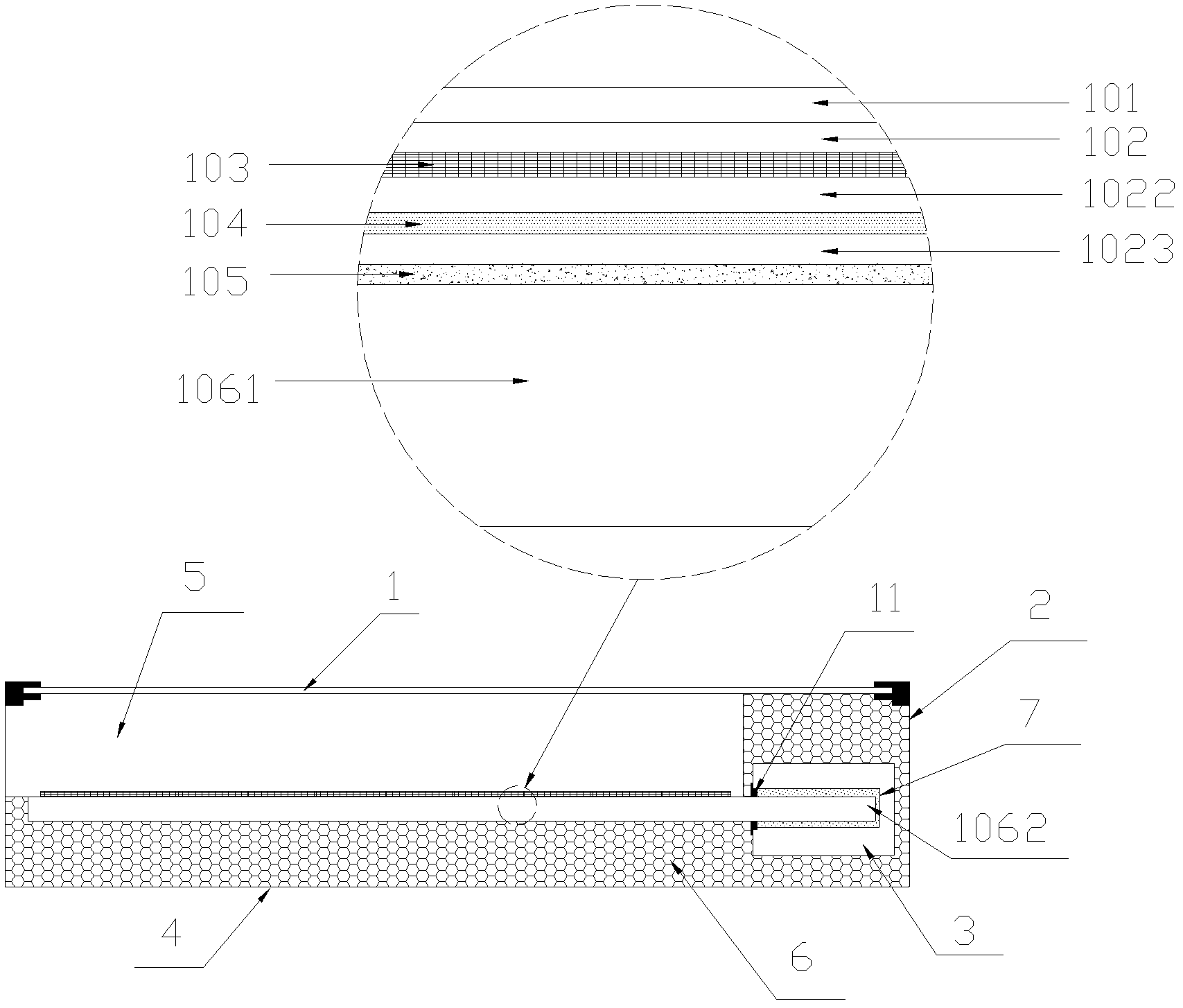

[0039] Such as figure 1 Shown is the front view of the structure of the flat plate heat pipe solar photovoltaic photothermal composite collector. figure 2 for figure 1 Cutaway side view of the collector shown.

[0040] see figure 1 with figure 2 , the flat plate heat pipe solar photovoltaic photothermal composite heat collector of the present invention comprises a photovoltaic photothermal composite assembly 10, a heat collector heat exchanger 3, a ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com